Method for preparing copper metal nanopowder having uniform oxygen passivation layer by using thermal plasma, and apparatus for preparing same

A metal powder and powder technology, which is applied in the field of preparing copper metal nano-powder with a uniform oxygen passivation layer by using thermal plasma and its preparation equipment, can solve the problems of high purity limitation, difficulty and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

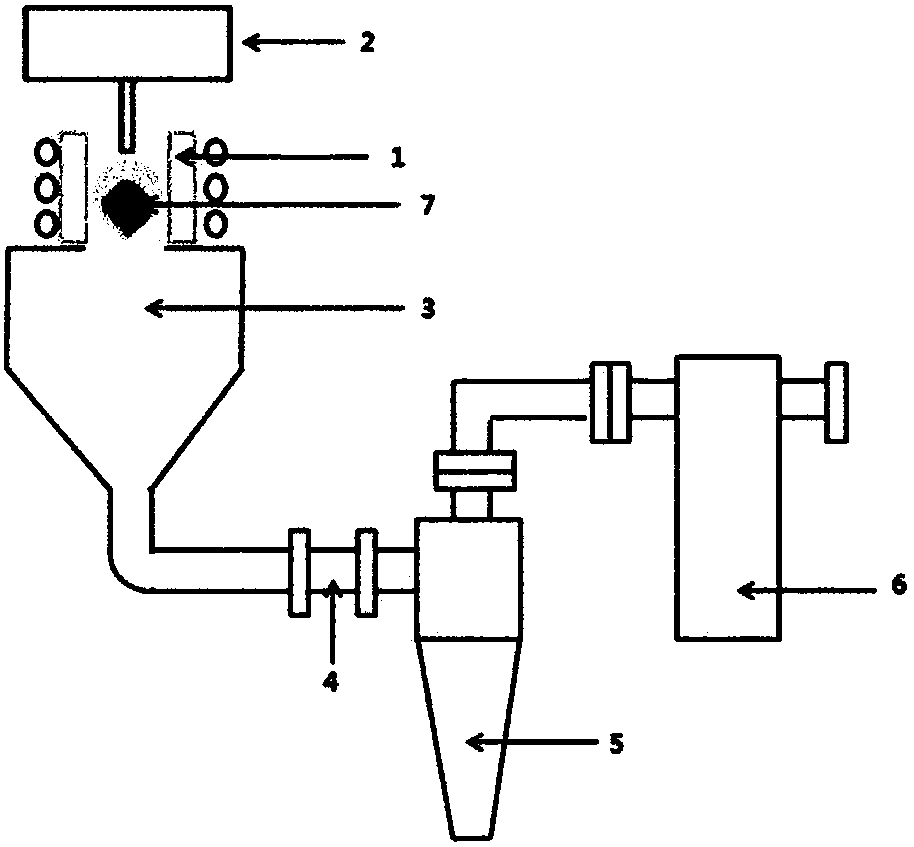

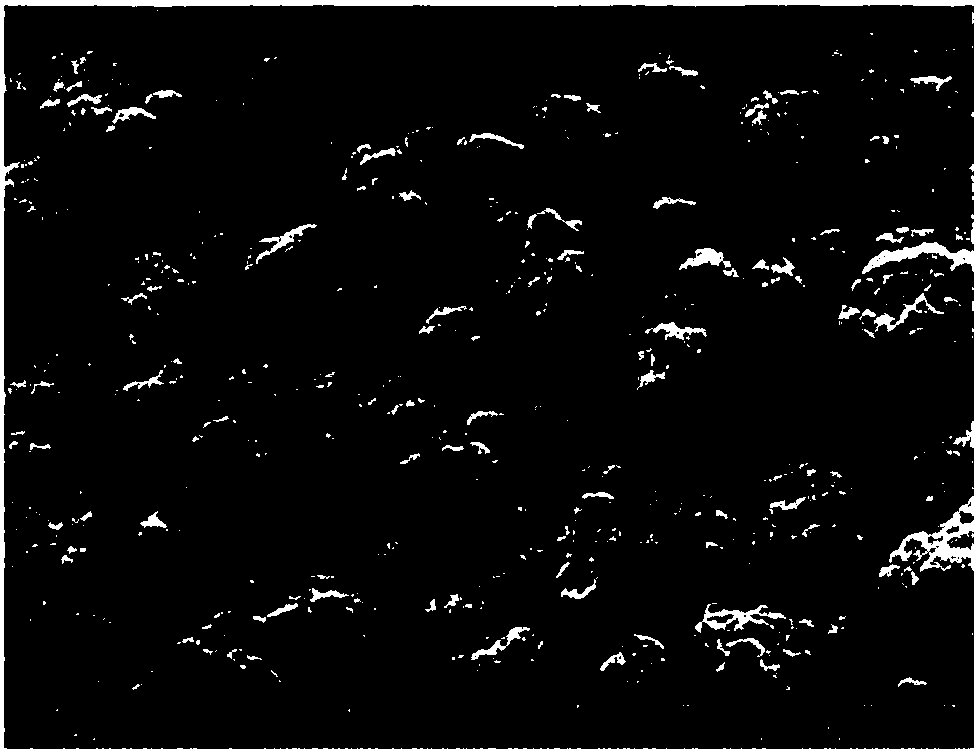

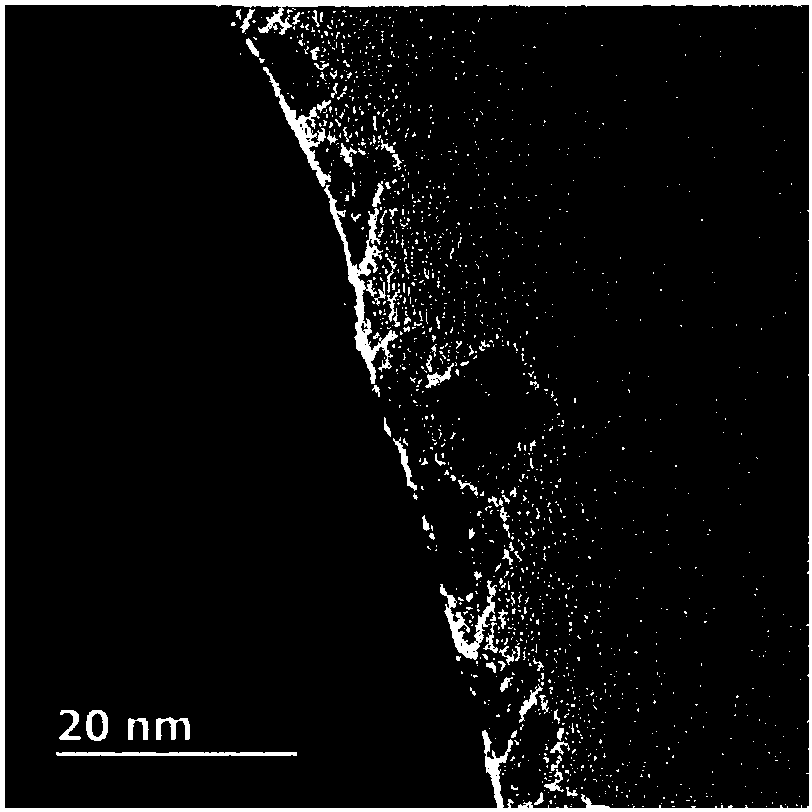

[0052] Copper powder having an average particle diameter of 12 μm and a purity of 96% was supplied into the plasma high temperature region by a raw material supplier at an injection rate of 0.5 kg / hr. Treatment with RF thermal plasma with 4MHz high-frequency power supply frequency, such as figure 1 As shown in , the raw material powder is melted due to thermal plasma. Under the condition that the amount of oxygen added is 1 slpm for 1 kg of copper or copper alloy powder injected per hour, oxygen passes through the oxygen reaction area to form a surface oxygen passivation layer. Afterwards, the oxygen that has passed through the reaction vessel to generate powder and the nano-copper metal powder that has been uniformly passivated by oxygen are collected by the collector. As a result, nano copper metal powder having an average particle diameter of 79 nm and an oxygen passivation layer having a thickness of 10 to 15 nm was prepared.

example 2

[0054] Nano copper metal powder having an average particle diameter of 98 nm and an oxygen passivation layer with a thickness of 8 to 10 nm was prepared in the same manner as Example 1 except that the injection rate of the copper powder was 0.9 kg / hr.

example 3

[0056] Nano copper metal powder having an average particle diameter of 120 nm and an oxygen passivation layer thickness of 5 to 8 nm was prepared in the same manner as Example 1 except that the injection rate of the copper powder was 1.2 kg / hr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com