Organic electroluminescent element

An electroluminescent element and luminescent technology, applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve problems that cannot be said to be sufficient, and achieve low driving voltage, improved injection and transmission efficiency, and improved hole transport efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

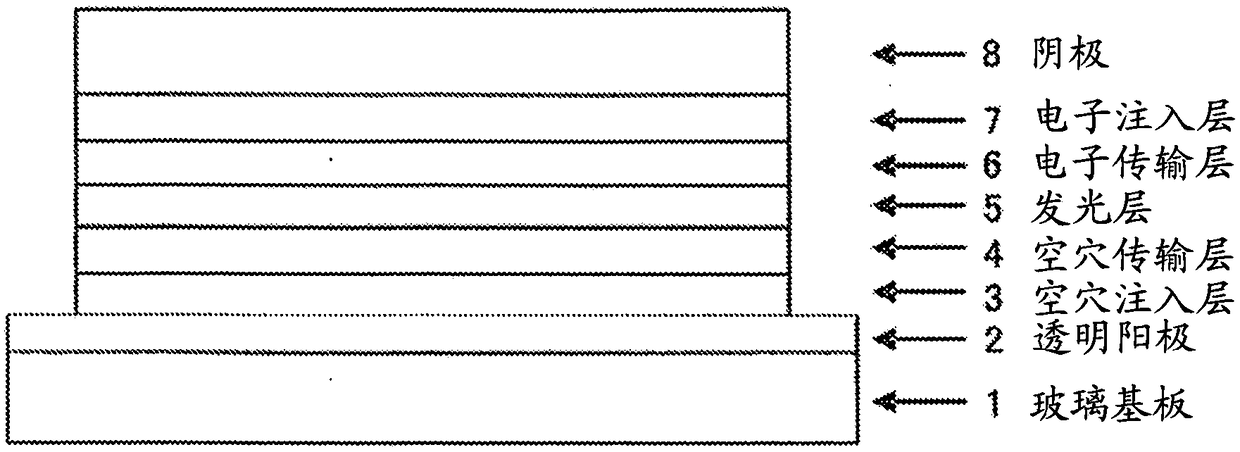

Image

Examples

Embodiment

[0387] Hereinafter, although an Example demonstrates embodiment of this invention concretely, this invention is not limited to the following Example.

Synthetic example 1

[0388]

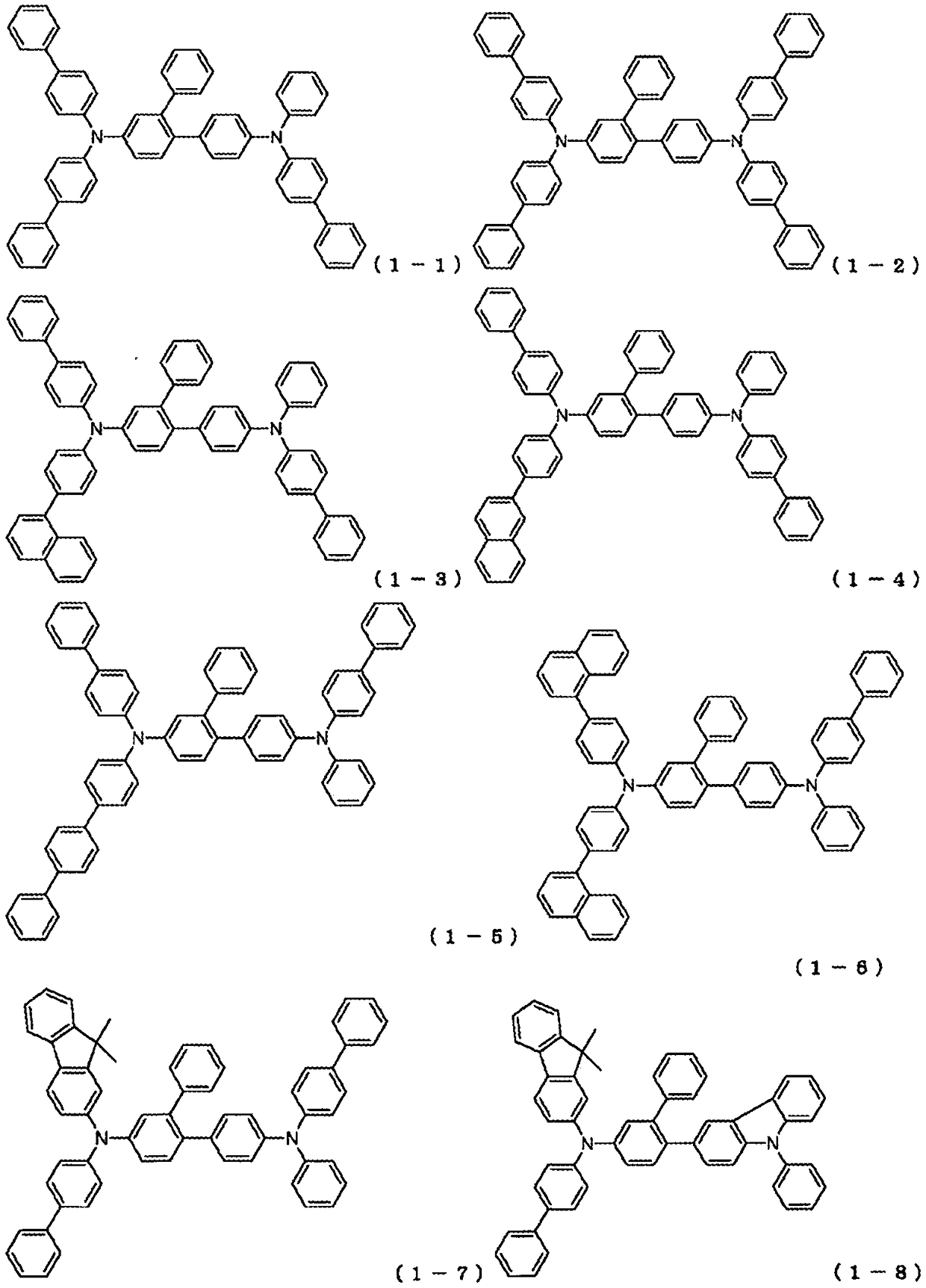

[0389] Synthesis of 4-bis(biphenyl-4-yl)amino-4'-{(biphenyl-4-yl)-phenylamino}-2-phenyl-biphenyl:

[0390] In a nitrogen-purged reaction vessel add

[0391]

[0392]

[0393] , heated, and stirred overnight at 100°C to obtain a reaction solution. The reaction liquid was cooled, and the organic layer was extracted by a liquid separation operation. The extracted organic layer was concentrated to obtain a crude product. The crude product was purified by column chromatography (carrier: silica gel, eluent: dichloromethane / heptane). As a result, 5.30 g of white powder of compound 1-1 was obtained (yield 37%).

[0394] For the obtained white powder, the structure was identified using NMR. use 1 H-NMR (CDCl 3 ) detected the following 44 hydrogen signals.

[0395] δ(ppm)=7.65-7.60(5H)

[0396] 7.59-7.53(5H)

[0397] 7.52-7.40(9H)

[0398] 7.39-7.21(15H)

[0399] 7.20-7.10(5H)

[0400] 7.09-6.91(5H)

[0401] [chemical 14]

[0402]

Synthetic example 2

[0403]

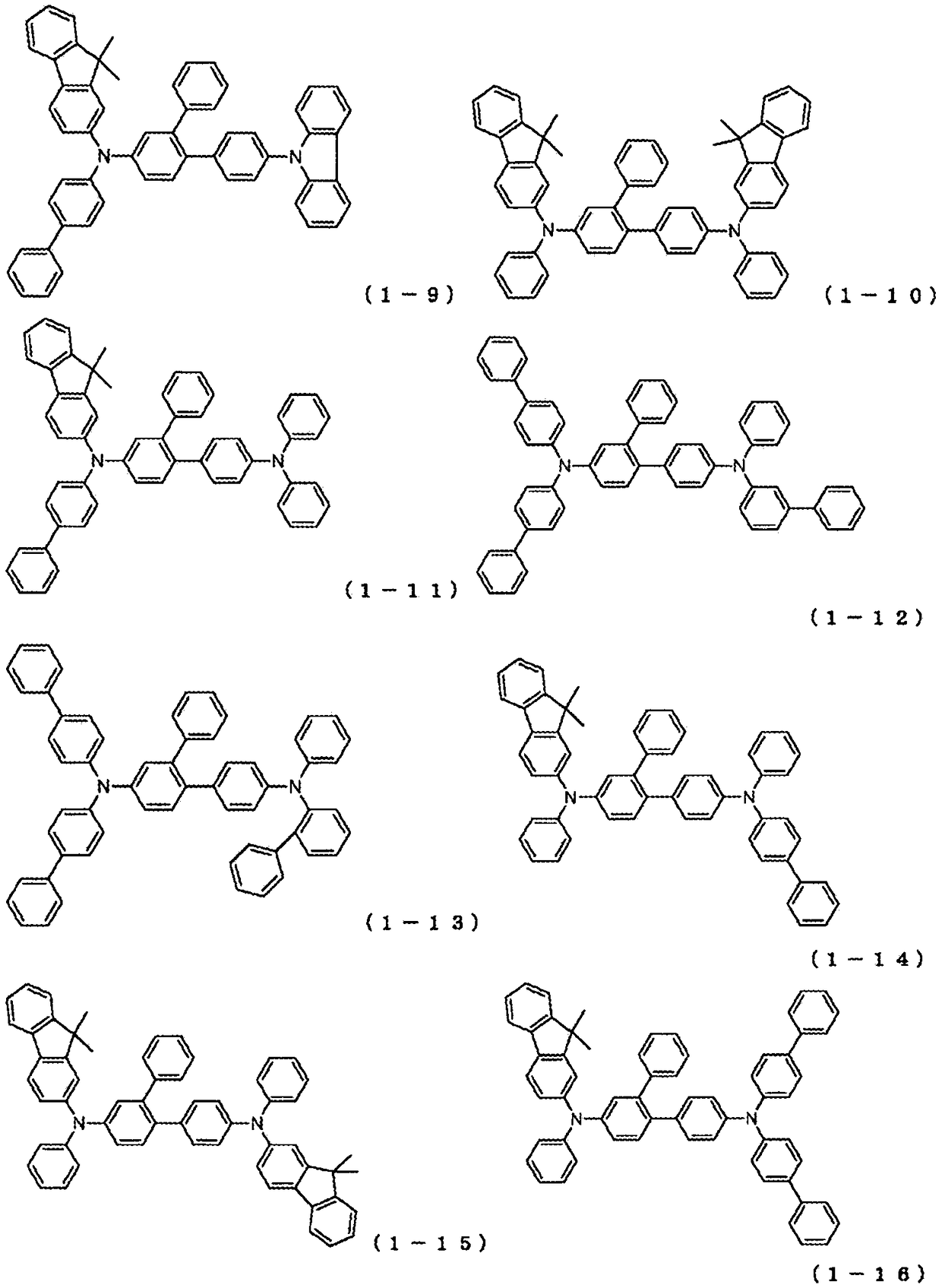

[0404] 4-{(biphenyl-4-yl)-(4-naphthalen-1-yl-phenyl)amino}-4'-{(biphenyl-4-yl)-phenylamino}-2-phenyl- Synthesis of biphenyl:

[0405] In Synthesis Example 1, (biphenyl-4-yl)-(6-bromobiphenyl-3-yl) was used instead of bis(biphenyl-4-yl)-(6-bromobiphenyl-3-yl)amine )-(4-naphthalen-1-yl-phenyl)amine, reacted under the same conditions. As a result, 9.70 g of an off-white powder of Compound 1-3 was obtained (69% yield).

[0406] For the obtained off-white powder, use NMR to identify the structure. use 1 H-NMR (CDCl 3 ) detected the following 46 hydrogen signals.

[0407] δ(ppm)=8.07(1H)

[0408] 7.93(1H)

[0409] 7.87(1H)

[0410] 7.67-7.54(7H)

[0411] 7.54-7.11(31H)

[0412] 7.69-6.92(5H)

[0413] [chemical 15]

[0414]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com