System to eliminate alkali metal oxides in smoke

A technology of alkali metal oxides and dust, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as inability to accurately control cleaning, achieve the effect of reducing downtime costs and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

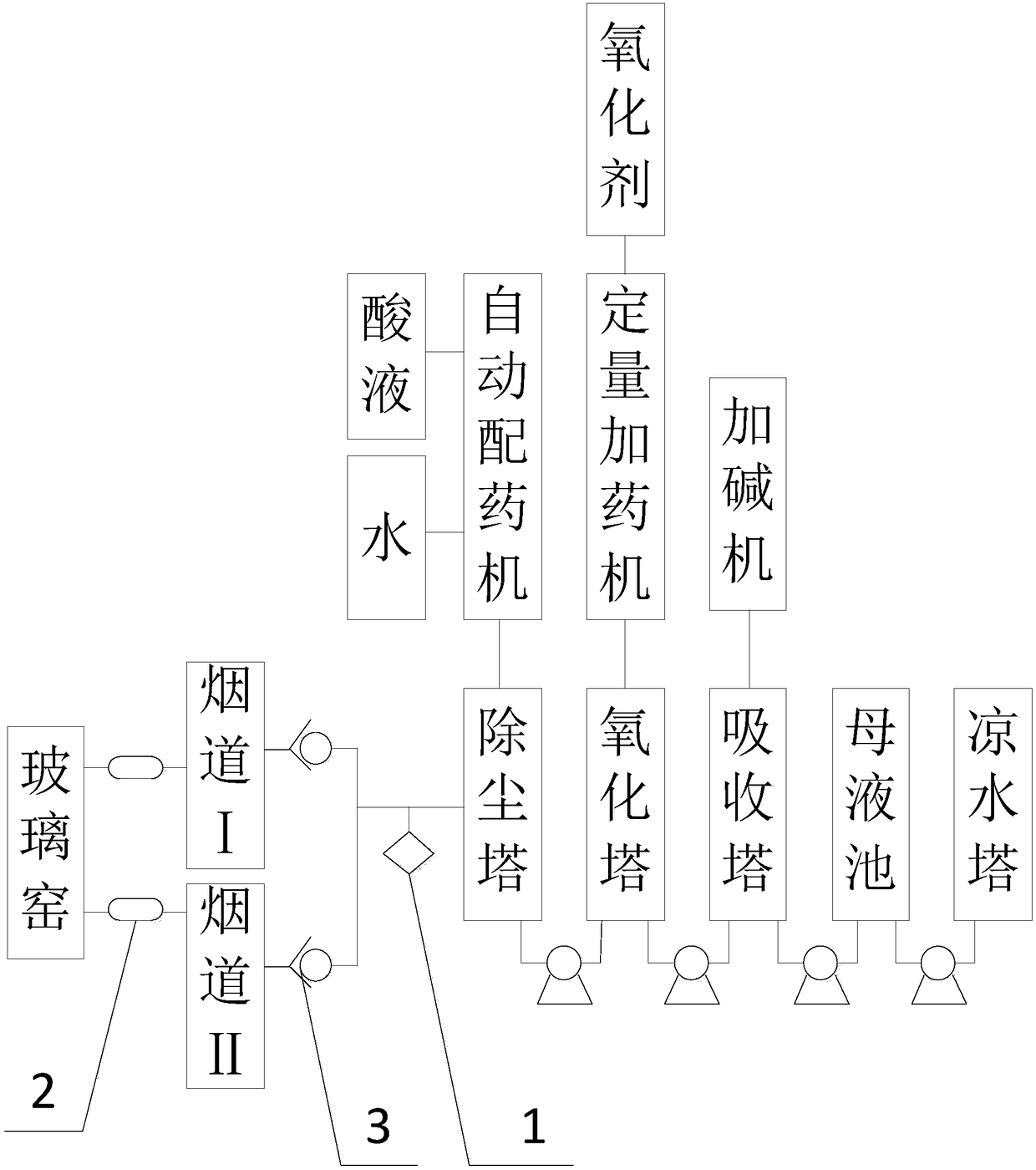

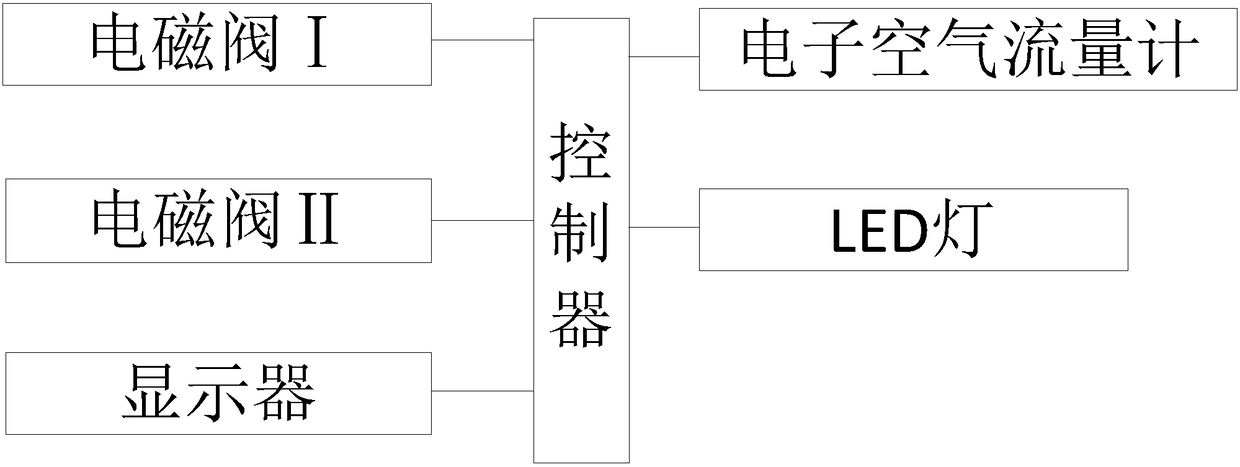

[0018] Such as Figure 1-Figure 2 As shown, the present invention removes the alkali metal oxide system in the dust, including the recording system and the dust removal equipment arranged at the outlet of the flue of the glass kiln. The glass kiln sends the flue gas produced by the production into the dust removal equipment through the flue. The dedusting equipment includes acid distributing equipment, oxygen distributing equipment, alkali adding machine and successively connected dedusting tower, oxidation tower, absorption tower, mother liquor pool and cooling water tower, the input end of the dedusting tower is connected with the outlet of the flue, so The acid distribution equipment is connected with the dust removal tower and sprays acid mist into the dust removal tower. The oxygen distribution equipment is connected with the oxidation tower and sprays strong oxidant into the oxidation tower. Alkali is added in the tower, and there are two flues, one end of which is conne...

Embodiment 2

[0023] A one-way valve 3 is connected between the flue and the main pipeline. One-way valve 3 to avoid flue gas backflow

[0024] Preferably, the LED lights are flashing LED lights.

Embodiment 3

[0026] The controller can adopt single chip microcomputer, ARM processor or PLC. Preferred single-chip microcomputer in the present invention, its model is preferably AT89LV51, the preferred LWGQ series gas turbine flowmeter of electronic gas flow meter, display adopts LED display screen or digital display screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com