Device with integral injection system for removing sulfur trioxide and NOx in flue gas

An injection system, sulfur trioxide technology, applied in the direction of gas treatment, chemical instruments and methods, membrane technology, etc., can solve problems such as uneven distribution, low adaptability of injection devices, and inability to achieve uniformity of base absorbents, etc., to achieve Extensive economic benefits and good environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

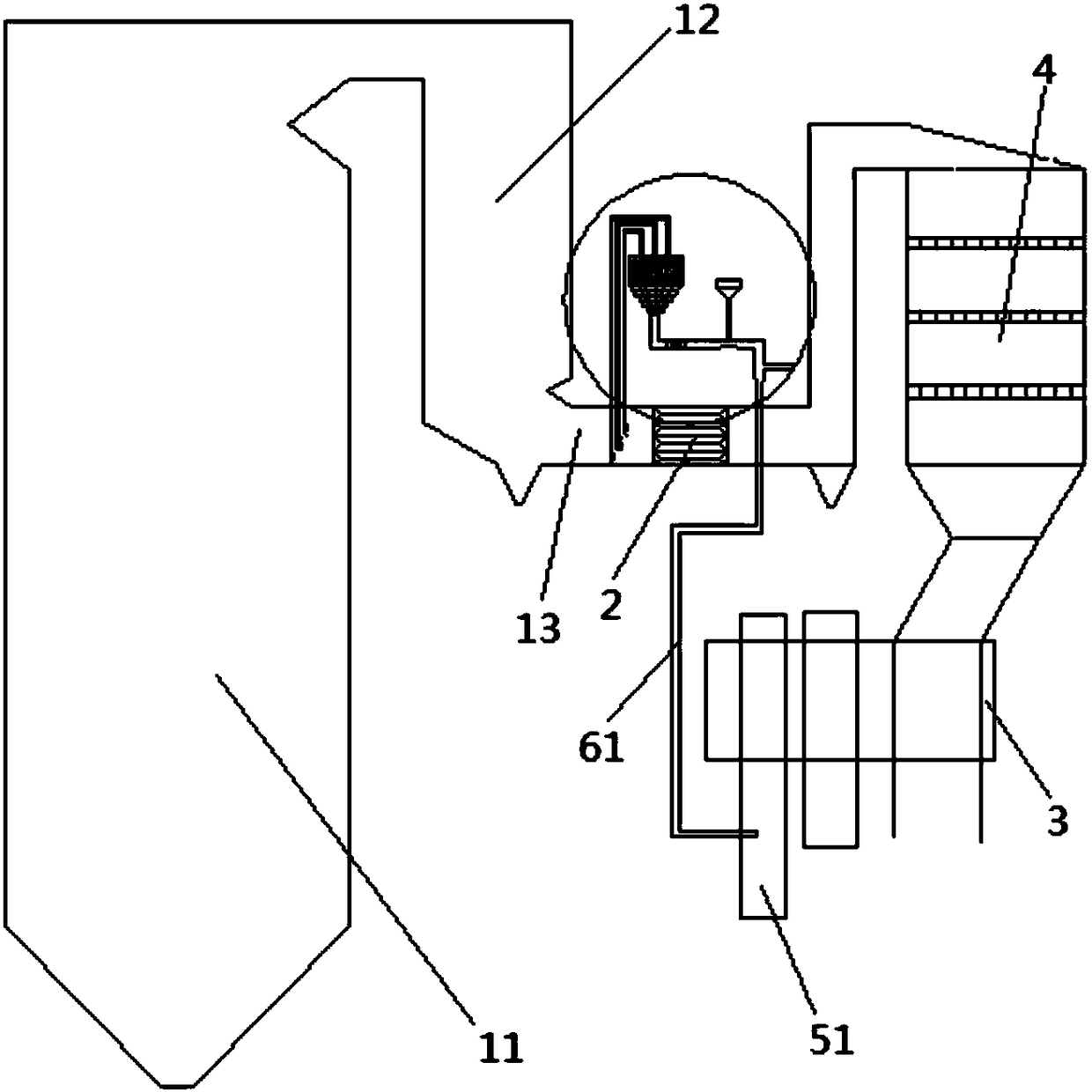

[0078] A 300MW coal-fired unit is equipped with two SCR reactors 4. Under the rated load and 6% oxygen, the flue gas volume at the outlet of the boiler 11 is 1,000,000m 3 / h, the temperature is 350°C, and the NOx concentration is 400mg / m 3 , SO 2 The concentration is 3000mg / m 3 , SO in the flue gas inside boiler 11 and SCR reactor 4 2 / SO 3 The conversions were 0.8% and 1.0%, respectively. In order to control the NOx emission concentration to be less than 40mg / m 3 and air preheater 3 outlet SO 3Concentration less than 10mg / m 3 , Design the device for removing sulfur trioxide and NOx in flue gas with integrated injection system.

[0079] 1. Material balance

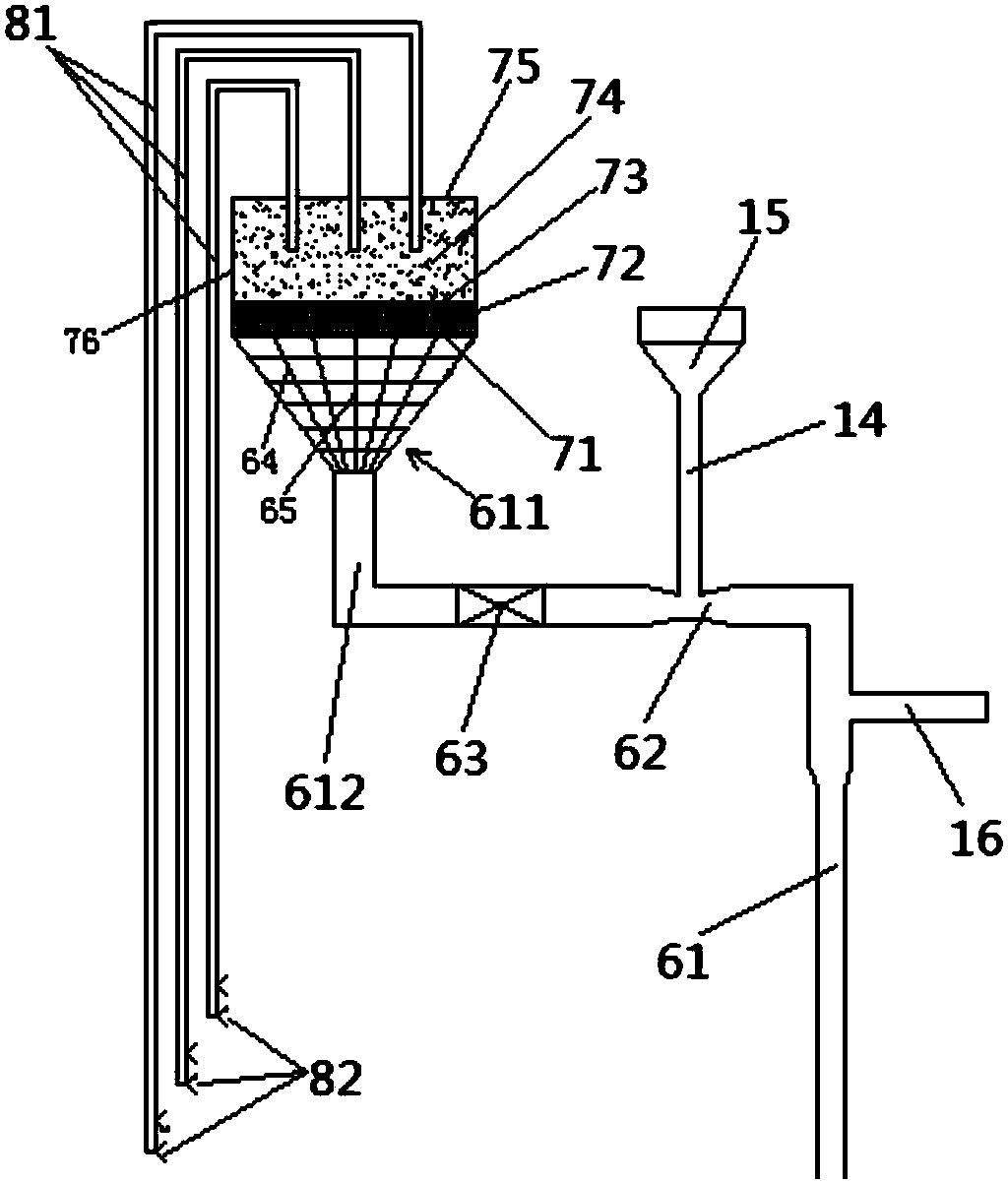

[0080] According to the design boundary conditions and performance index requirements, the calculated ammonia consumption is 133kg / h, and the dilution air volume of 5% volume concentration is 3506m 3 / h, the ammonia injection dilution air volume at the 4 inlets of each SCR reactor is 1753m 3 / h.

[0081] Conside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com