Method for preparing anthraquinone by anthracene oxidation method

An oxidation method and anthraquinone technology, applied in the preparation of oxidized quinones, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve strong oxidative and strong corrosive equipment damage, unfavorable industrialization, etc. problems, to achieve the effect of low cost, sufficient raw materials and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] 1. γ-Al 2 o 3 Determination of adsorption capacity

[0055] The saturated adsorption capacity of the carrier needs to be determined before preparing the supported catalyst by the equal volume impregnation method. The method is as follows: Then weigh 5.00 grams of carrier γ-Al 2 o 3 , add distilled water dropwise to saturation, the amount of water used (3.5ml) is the saturated adsorption capacity Vp of the carrier (unit: mL / g).

[0056] 2. Preparation of catalysts with different components

[0057] FeN 3 o 9 9H 2 O is an active component, wherein the amount concentration ratio (Table 3) of the prepared substance is: n(Fe):n(Al)=0.02:1, 0.04:1, 0.06:1, 0.08:1, 0.1:15 single-supported catalyst. Number the five kinds of active components and carrier mixtures separately and seal them with plastic wrap, soak them at room temperature for 6-8 hours, put the soaked samples in a drying oven at a controlled temperature of 120°C and dry them for 6-7 hours. The process requ...

experiment example

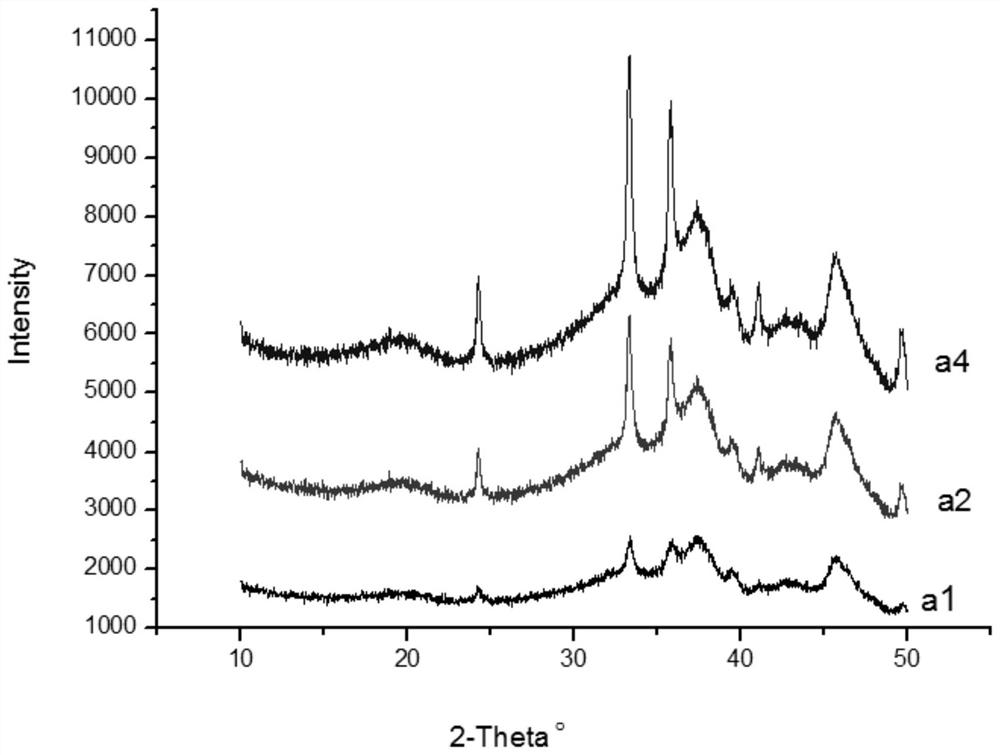

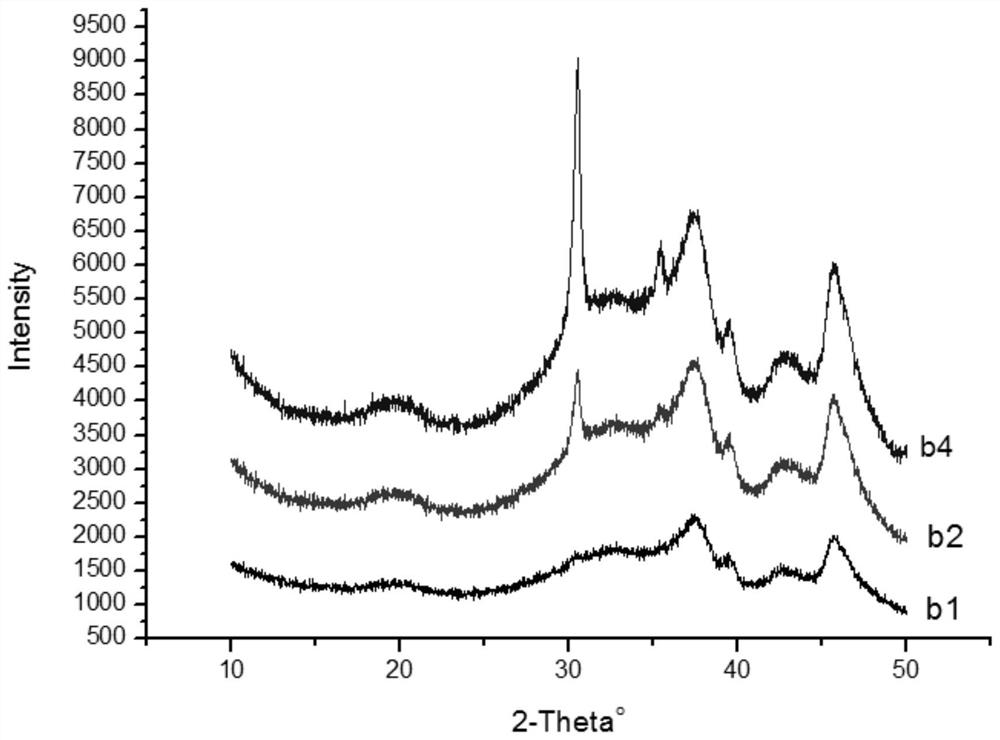

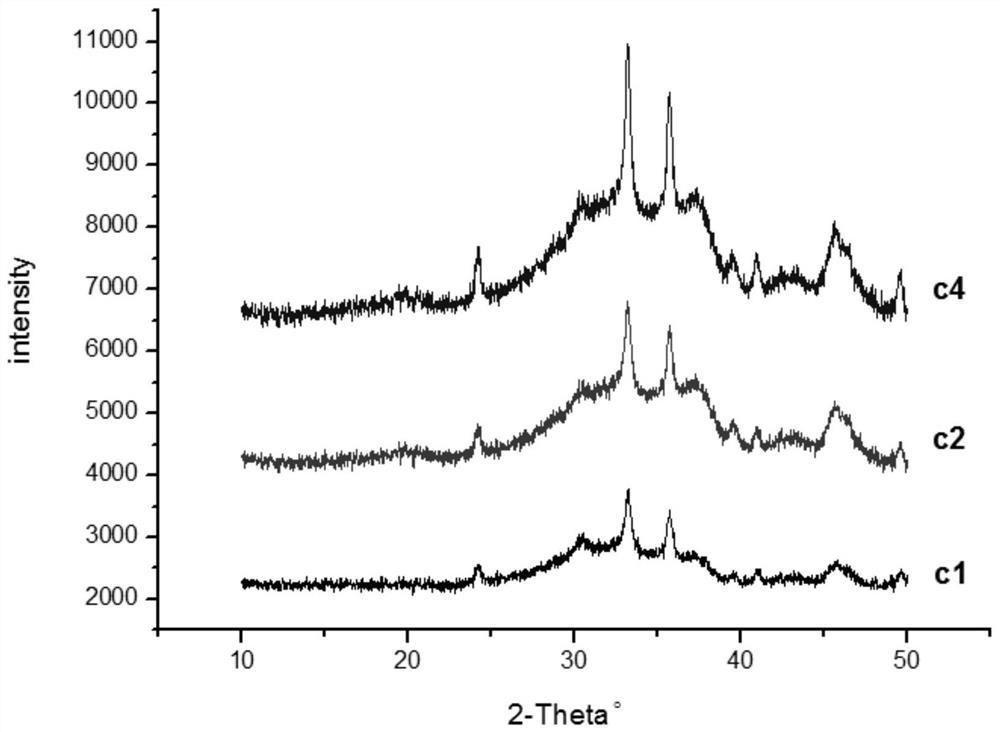

[0064] Experiment with γ-Al 2 o 3 As the carrier, Fe and Zr oxides are the active components, and the Fe-γ-Al is prepared by the equal volume impregnation method 2 o 3 , Zr-γ-Al 2 o 3 Single supported catalyst and Fe-Zr / γ-Al 2 o 3 dual-supported catalyst. Investigate the influence of the structure of catalysts with different active components on the yield of anthraquinone under normal pressure and low temperature, analyze the product by ultra-high performance liquid chromatography, and evaluate the catalytic performance of the catalyst in the reaction of anthracene oxidation to anthraquinone. XRD characterization analyzed the crystal situation in the catalyst.

[0065] Experimental Reagents and Instruments

[0066] Table 1 Main experimental reagents

[0067]

[0068] Table 2 Main Experimental Instruments

[0069]

[0070] Table 3 Distribution ratio of Fe / Al, Zr / Al single-loaded active components

[0071]

[0072] Table 4 Distribution ratio of Fe-Zr / Al doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com