Preparation method for supramolecular assembly body based on polyvinyl alcohol and cyclopolysaccharide

A supramolecular assembly, polyvinyl alcohol technology, applied in the field of polymer material functionalization, can solve the problems of unsuitable melt processing, the melting point and thermal decomposition temperature of polyvinyl alcohol are close, and achieve good solubility, easy separation and purification, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

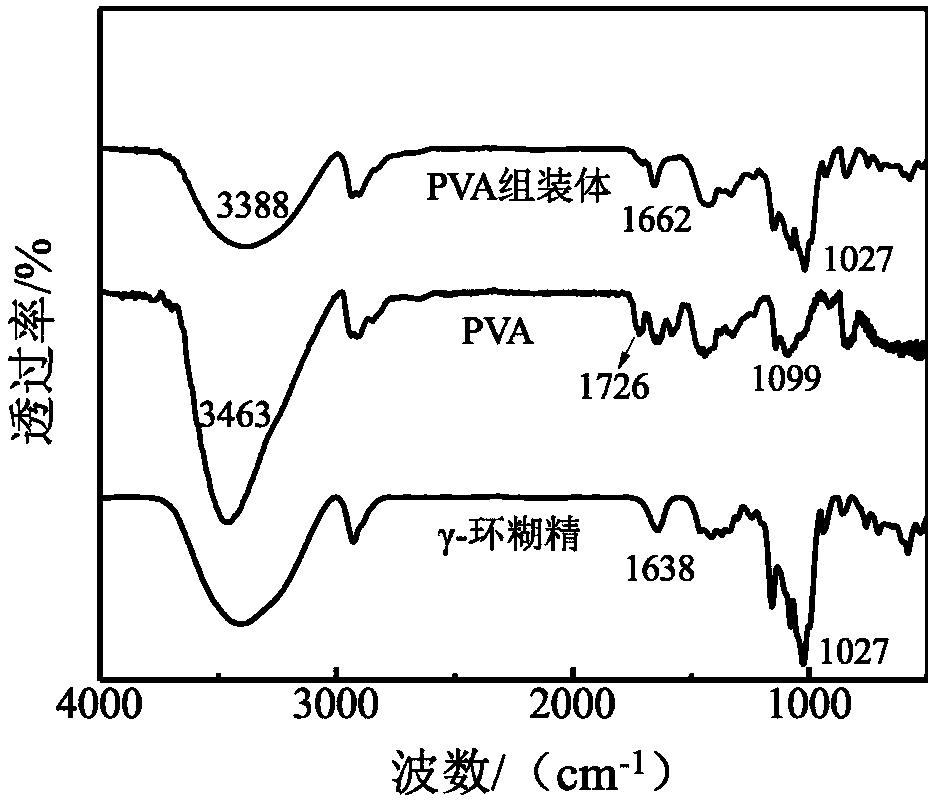

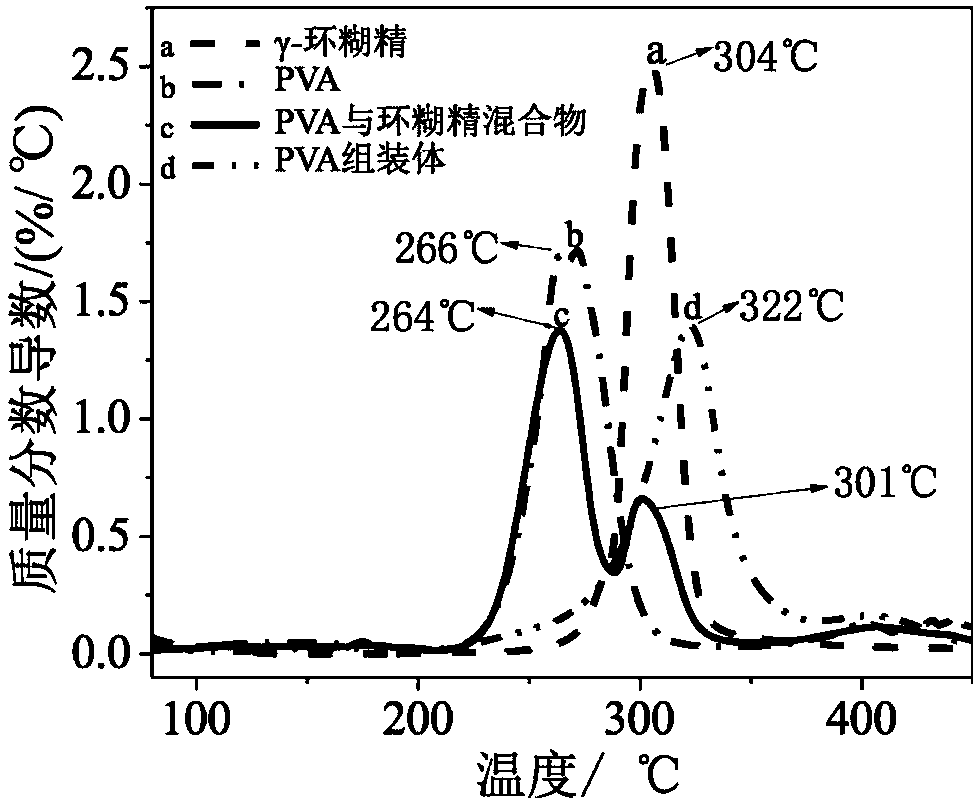

[0018] With cyclopolysaccharide γ-cyclodextrin as the main molecule, the molecular weight Mw=0.9×10 4 g / mol, polyvinyl alcohol with a degree of alcoholysis of 80% is the guest molecule, and the polyvinyl alcohol supramolecular assembly is prepared, and the specific steps are as follows:

[0019] ① Add 0.25g of the above PVA solid to 50mL of distilled water to prepare a PVA dilute solution.

[0020] ②Dissolve 0.5g of γ-cyclodextrin solid powder into the above dilute polyvinyl alcohol solution, gradually raise the temperature to 70°C within 5 minutes, condense and reflux, stir for 4 hours, cool down to 25°C, and continue stirring for 10 hours. The above reaction process was repeated 3 times.

[0021] ③ After the reaction is finished, add 20 mL of the concentrated solution obtained by rotary evaporation of the above solution dropwise into 120 mL of cold ethanol, and stir to obtain a precipitate. The resulting precipitate was centrifuged at a speed of 10000 r / min. The precipita...

Embodiment 2

[0024] With cyclopolysaccharide β-cyclodextrin as the main molecule, the molecular weight Mw=0.9×10 4 g / mol, polyvinyl alcohol with a degree of alcoholysis of 80% is the guest molecule, and the polyvinyl alcohol supramolecular assembly is prepared, and the specific steps are as follows:

[0025] ① Add 0.25g of the above PVA solid to 50mL of distilled water to prepare a PVA dilute solution.

[0026] ②Dissolve 2.5g of β-cyclodextrin solid powder into the above dilute PVA solution, gradually raise the temperature to 80°C within 5 minutes, condense and reflux, stir for 4 hours, cool down to 20°C, and continue stirring for 12 hours. The above reaction process was repeated 4 times.

[0027] ③ After the reaction is finished, add 20 mL of the concentrated solution obtained by rotary evaporation of the above solution dropwise into 120 mL of cold ethanol, and stir to obtain a precipitate. The resulting precipitate was centrifuged at a speed of 10000 r / min. The precipitated product obta...

Embodiment 3

[0029] With cyclopolysaccharide α-cyclodextrin as the main molecule, the molecular weight Mw=0.2×10 4 g / mol, polyvinyl alcohol with a degree of alcoholysis of 80% is the guest molecule, and the polyvinyl alcohol supramolecular assembly is prepared, and the specific steps are as follows:

[0030] ① Add 0.25g of the above PVA solid to 50mL of distilled water to prepare a PVA dilute solution.

[0031] ②Dissolve 1.0g of α-cyclodextrin solid powder into the above dilute PVA solution, gradually raise the temperature to 90°C within 5 minutes, condense and reflux, stir for 8 hours, cool down to 4°C, and continue stirring for 24 hours. The above reaction process was repeated 8 times.

[0032] ③ After the reaction was completed, 20 mL of the concentrated solution obtained by rotary evaporation of the above solution was added dropwise to 150 mL of methanol, and stirred to obtain a precipitate. The resulting precipitate was centrifuged at a speed of 10000 r / min. The precipitated produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com