Composite material of modified carbon fibers and nanoaramid fibers and preparation method of composite material

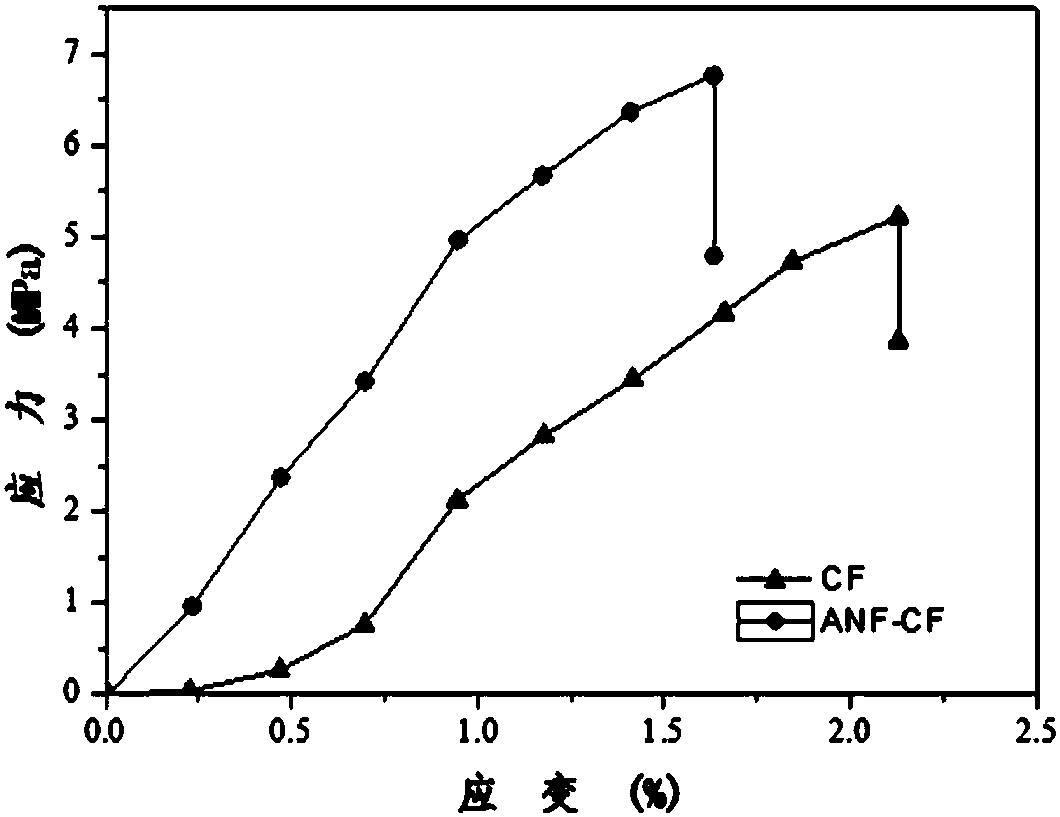

A technology of aramid fibers and composite materials, which is applied in the field of composite fiber preparation, can solve the problems of restricting the performance of carbon fiber and aramid fiber composite materials, lack of chemically active functional groups, poor deposition effect, etc., and achieve enhanced adhesion and Hydrophilic, excellent mechanical properties, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]This embodiment provides a composite material of modified carbon fiber / nano-aramid fiber and a preparation method thereof.

[0052] (1) Weighing 2g of carbon fiber, cleaning, filtering and drying the carbon fiber with lye in sequence, and then ultrasonically cleaning, filtering and drying the carbon fiber with deionized water again to obtain pretreated carbon fiber.

[0053] (2) Dissolving the pretreated carbon fiber in Tris-HCl buffer solution with pH=8.5, adding 0.5g / L dopamine solution, mixing and soaking for 24 hours. Then filter the solution, wash the precipitate with water, and dry to obtain the dopamine-modified carbon fiber.

[0054] (3) Dissolve the dopamine-modified carbon fiber in 50mL of DMSO solution, stir well, slowly add 0.5g of NaOH solid powder, then place it in a constant temperature water bath at 60°C, and then add 5mL of 2,3-epoxypropyltri Methylammonium chloride, fully stirred, and then filtered to obtain a precipitate, which was washed with DMSO an...

Embodiment 2

[0062] This embodiment provides a composite material of modified carbon fiber / nano-aramid fiber and a preparation method thereof.

[0063] (1) Weighing 5 g of carbon fiber, washing, filtering and drying the carbon fiber with lye in sequence, and then ultrasonically cleaning, filtering and drying the carbon fiber with water again to obtain pretreated carbon fiber.

[0064] (2) Dissolve the pretreated carbon fibers in a Tris-HCl buffer solution with pH=8.5, add 2.5g / L dopamine solution, mix and soak for 36 hours. Then filter the solution, wash the precipitate with water, and dry to obtain the dopamine-modified carbon fiber.

[0065] (3) Dissolve the dopamine-modified carbon fiber in 150mL of DMSO solution, stir well, slowly add 1.5g of KOH solid powder, then place it in a constant temperature water bath at 60°C, and then add 15mL of 2,3-epoxypropyl trimethylammonium chloride, fully stirred, and then filtered to obtain a precipitate, which was washed with DMSO and deionized wate...

Embodiment 3

[0071] This embodiment provides a composite material of modified carbon fiber / nano-aramid fiber and a preparation method thereof.

[0072] (1) Weighing 3g of carbon fiber, washing, filtering and drying the carbon fiber with lye in sequence, and then ultrasonically cleaning, filtering and drying the carbon fiber with water again to obtain pretreated carbon fiber.

[0073] (2) Dissolving the pretreated carbon fiber in Tris-HCl buffer solution with pH=8.5, adding 1.5g / L dopamine solution, mixing and soaking for 30h. Then filter the solution, wash the precipitate with water, and dry to obtain the dopamine-modified carbon fiber.

[0074] (3) Dissolve the dopamine-modified carbon fiber in 150mL of DMSO solution, stir well, slowly add 2.0g of KOH solid powder, then place it in a constant temperature water bath at 60°C, and then add 8mL of 2,3-epoxypropyl trimethyl ammonium chloride, fully stirred, and then filtered to obtain a precipitate, which was washed with DMSO and deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com