Preparation method of PBO fiber composite material with high-temperature dielectric property

A technology of fiber composite materials and dielectric properties, which is applied in fiber types, fiber processing, textiles and papermaking, etc., can solve the problems of PBO fiber interface performance and poor high temperature resistance, and achieve improved interface properties and good dielectric properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: what this embodiment records is a kind of preparation method of high temperature dielectric performance PBO fiber composite material, described method comprises the following steps:

[0024] Step 1: Preparation of grafting liquid: put the homemade hyperbranched PBO polymer and polyphosphoric acid in a 500 mL three-necked bottle at a mass ratio of 1:125 to 150, and use an electric stirrer under a nitrogen atmosphere at 100 Stir at a speed of ~500 r / min to completely dissolve it to make a grafting liquid; the electric stirrer is the DJ1C booster electric stirrer produced by Jintan Dadi;

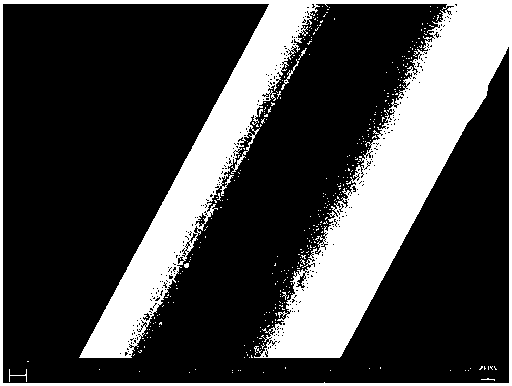

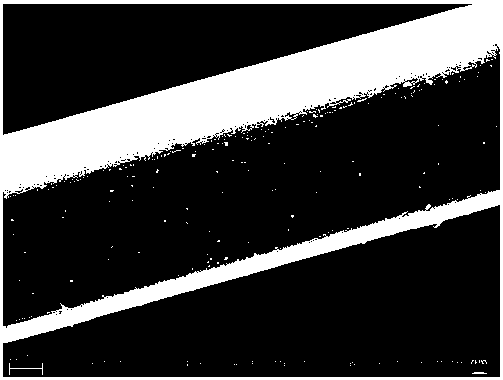

[0025] Step 2: Infiltration treatment of PBO fibers: Take 10-20 m of laboratory-made and cleaned PBO fibers to make PBO fiber bundles, tie both ends with polytetrafluoroethylene tapes, and place the PBO fiber bundles on the PBO fiber bundles prepared in step 1. In the grafting liquid, conduct ultrasound to fully infiltrate the PBO fiber bundles with the grafting ...

specific Embodiment approach 2

[0029] Embodiment 2: In Embodiment 1, a method for preparing a PBO fiber composite material with high-temperature dielectric properties, in step 1, the electric stirring time is 4-6 h, and the stirring temperature is 110-160°C.

specific Embodiment approach 3

[0030] Embodiment 3: In the method for preparing a high-temperature dielectric PBO fiber composite material described in Embodiment 1, in step 2, the ultrasonic time is 5-10 min, and the ultrasonic power is 120 W.

[0031] Embodiment 4: In the method for preparing a high-temperature dielectric PBO fiber composite material described in Embodiment 1, in step 3, the heating temperature in the water bath is 80-90 °C, and the time is 1-2 h.

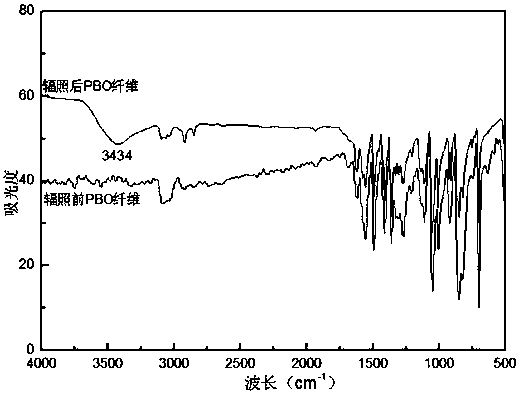

[0032] Specific embodiment five: the preparation method of a kind of high-temperature dielectric performance PBO fiber composite material described in specific embodiment one, in step four, described Co 60 The dose of γ-ray irradiation was 30-40 kGy, and the irradiation time was 15-20 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com