High-temperature chlorine corrosion resistant coating and preparation method thereof

A technology of chlorine corrosion and high temperature resistance, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, alkali metal silicate coatings, etc., and can solve the problems that the anti-chlorine corrosion affects the service life and effect of the coating, and the anti-chlorine corrosion needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The application also provides the preparation method of the high temperature chlorine corrosion resistant coating, comprising:

[0038] Mixing 20-35wt% binder with water to obtain binder liquid;

[0039] The binder liquid is mixed with 20-30wt% filler, and the high temperature chlorine corrosion resistant coating is obtained after grinding.

[0040] In the preparation process of the above-mentioned preparation of high-temperature chlorine corrosion resistant coatings, the binder is first mixed with water to obtain a binder liquid; after the binder liquid is obtained, the binder liquid is mixed with a filler, and then preferably added After the additive is stirred and ground, the high temperature chlorine corrosion resistant coating can be obtained.

[0041] In order to prevent the carbon nanotubes from being broken during the grinding process, the grinding is preferably performed using a planetary ball mill, and the time of the ball milling is 1-2 hours.

[0042] The ...

Embodiment

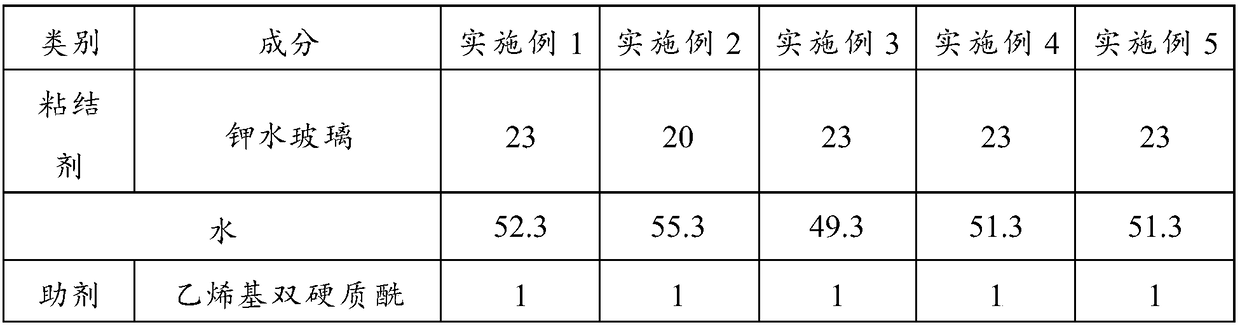

[0045] Mix the binder potassium silicate with water to obtain a binder liquid, then add three additives such as a dispersant vinyl bis stearamide, a defoamer n-octanol and a rheological agent organic bentonite, and add fillers, wherein the fillers include: barium Glass powder, carbon nanotubes, aluminum oxide are then filtered and packaged after being ground by a planetary ball mill for 1 hour to obtain the coating; the above-mentioned coating can be divided into 5 embodiments according to the content of the specific components, and the ceramics of embodiments 1 to 5 are The paint component content data table is as shown in Table 1:

[0046] Table 1 Embodiment 1~Example 5 Ceramic coating material each group material content and specification data (wt%)

[0047]

[0048]

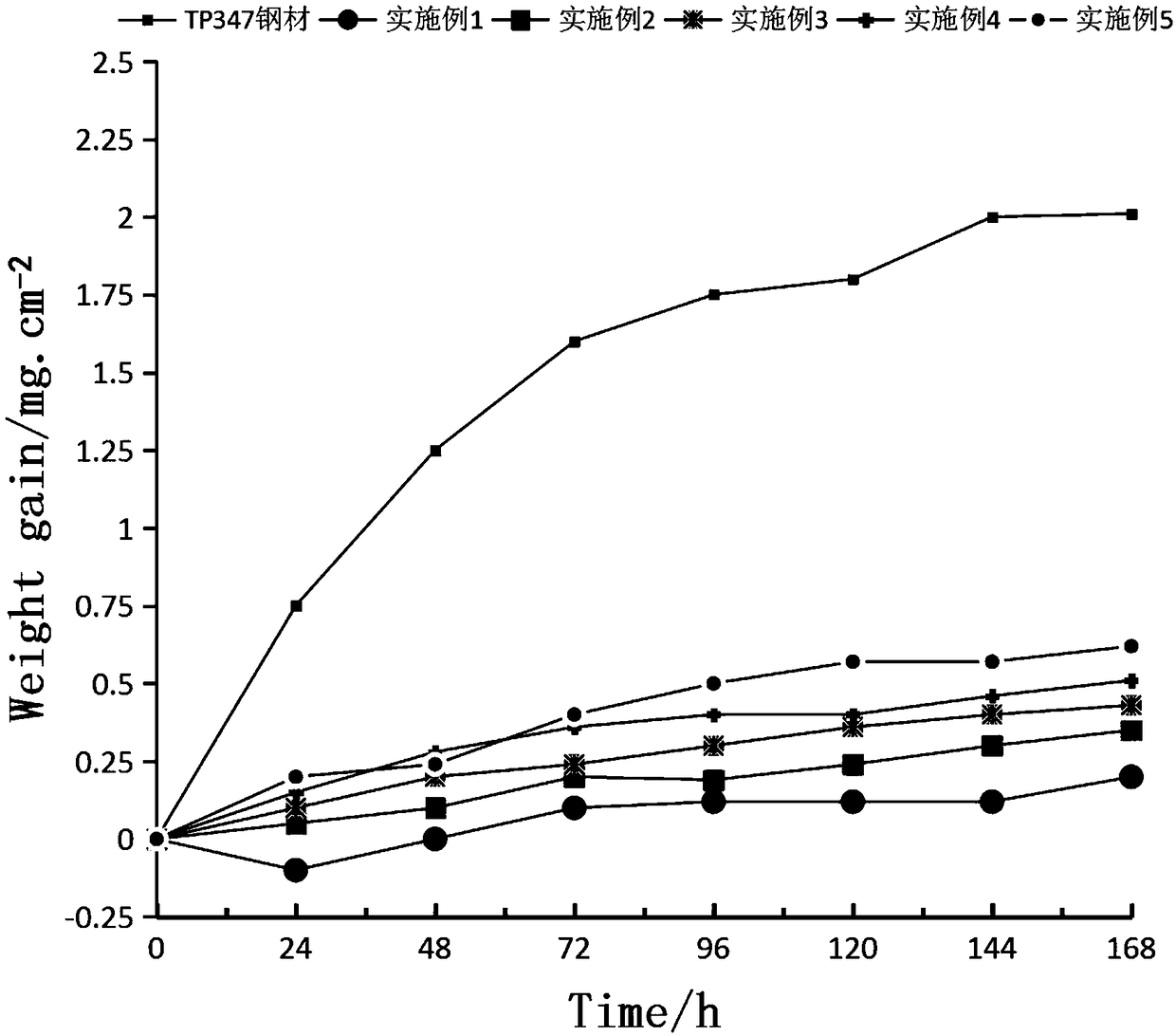

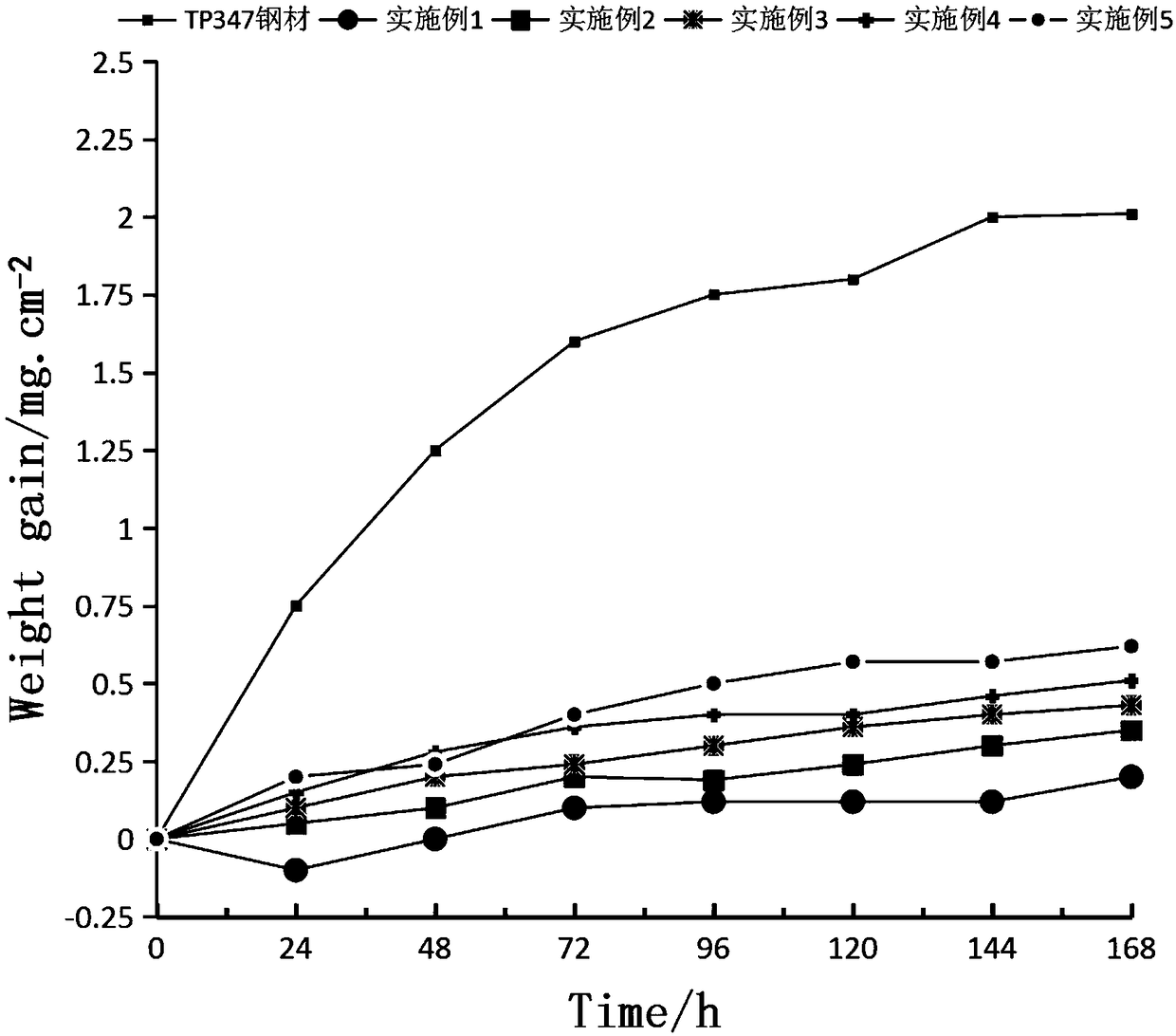

[0049] The coatings in Examples 1 to 5 were sprayed on the surface of the 20G steel material commonly used in boiler water walls, and their high-temperature chlorine corrosion resistance was tested;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com