Water-based paint for metal surface and preparation method thereof

A technology of water paint and deionized water, which is applied to the device, coating, epoxy resin coating and other directions of coating liquid on the surface, which can solve the problem of water paint to be developed, and achieve high hardness, fullness, and good gloss. , low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

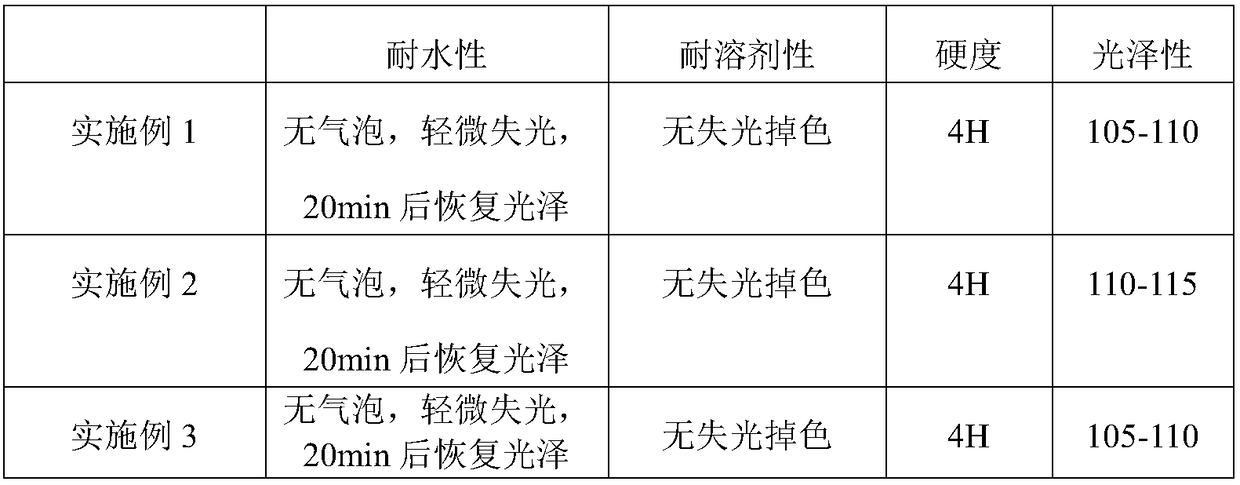

Embodiment 1

[0066] In this example, the water paint was prepared according to the following method:

[0067] 1. Raw materials

[0068] The dispersion of 65 parts by weight, the full methyl etherified amino resin of 10 parts by weight (purchased from Cytec), the dimethylethanolamine of 0.2 parts by weight, the defoamer (Tego-902w of Tego Company of Tego Company) of 0.2 parts by weight; The BYK-024 of BYK company, mass ratio is 1:1), the deionized water of 15 weight parts, the substrate wetting and leveling agent of 0.2 weight part (Tego-4100 of Tego company; And the BYK-346 of BYK company, The mass ratio is 1:1), 0.5 parts by weight of surface leveling agent (PW336 of Xianchuang Company), and 0.2 parts of thickener (OMG0620 of OMG Company).

[0069] 2. Steps

[0070] (1) 25 parts by weight of E-20 epoxy resin and 15 parts by weight of E-12 epoxy resin, 3 parts by weight of polyethylene glycol 4000, 2 parts by weight of polyethylene glycol 6000 are dropped into the reaction vessel, and th...

Embodiment 2

[0075] Prepare water paint according to the method for embodiment 1, difference is that raw material is as follows:

[0076] The dispersion of 70 parts by weight, the amino resin of 12 parts by weight, the neutralizing agent of 0.4 parts by weight, the defoamer of 0.4 parts by weight, the deionized water of 20 parts by weight, the substrate wetting and leveling agent of 0.5 parts by weight, 1 part by weight of surface leveling agent and 0.5 part by weight of thickener.

Embodiment 3

[0078] Prepare water paint according to the method for embodiment 1, difference is that raw material is as follows:

[0079] The dispersion of 68 parts by weight, the amino resin of 11 parts by weight, the neutralizing agent of 0.3 parts by weight, the defoamer of 0.3 parts by weight, the deionized water of 18 parts by weight, the substrate wetting and leveling agent of 0.4 parts by weight, 0.8 parts by weight of surface leveling agent and 0.4 parts by weight of thickener.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap