Forming paper with low-heat-conducting performance for low-temperature cigarette nozzle bar

A low-temperature cigarette, low thermal conductivity technology, applied in the field of forming paper, can solve the problems of increasing the difficulty of cooling the flue gas, reducing the diameter of the hollow cavity, reducing the diameter of the flue gas channel, etc., achieving good lateral heat insulation effect, reducing flue gas temperature, The effect of large flue gas channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

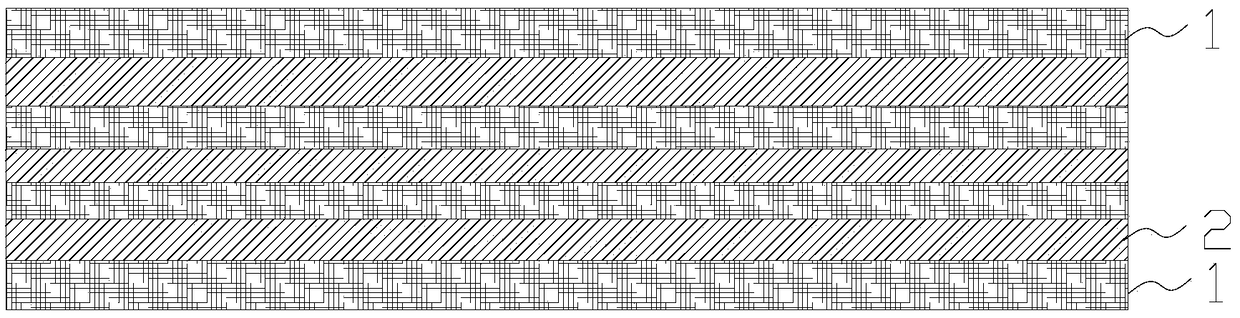

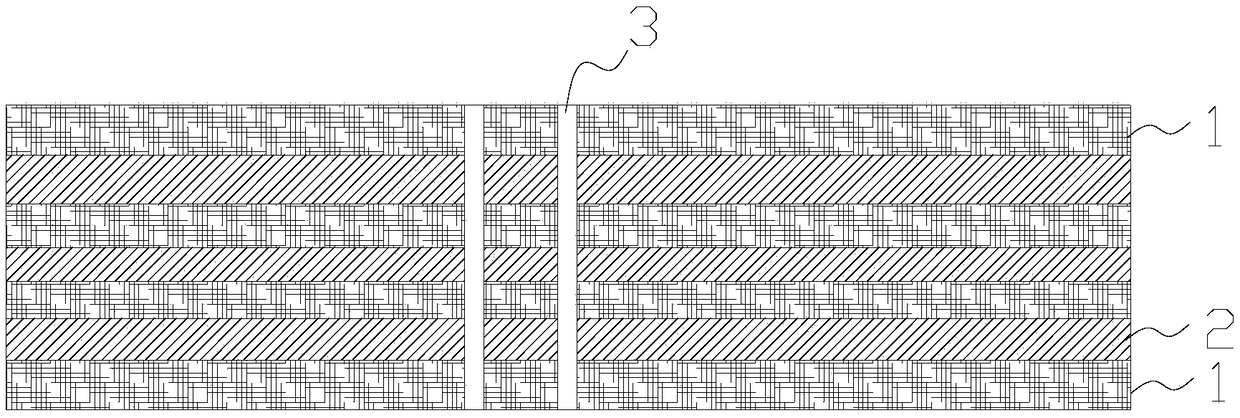

[0017] see figure 1 , a forming paper with low thermal conductivity for low-temperature cigarette tip rods, which is formed by alternate bonding of plant fiber paper 1 and organic plastic film paper 2, and the outermost layer is plant fiber paper 1, and the gap between adjacent layers Glyceryl triacetate is used for bonding, and the plant fiber paper 1 is usually made of wood pulp, straw pulp or hemp pulp without adding any inorganic salt filler or adding 1 to 15% of pulp equivalent silica particles in the papermaking process. , the organic plastic film paper 2 is polyethylene terephthalate plastic paper, polyvinyl chloride plastic paper or polylactic acid plastic paper.

[0018] The present invention adopts plant fiber paper and organic plastic film paper, and its thermal conductivity is relatively lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com