Method for preparing dry bonded structure surface through direct metal laser ablation

A structured surface, laser direct technology, used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of high-cost manufacturing process, low output, dislocation, etc., achieve good metal properties, wide selectivity, avoid destabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

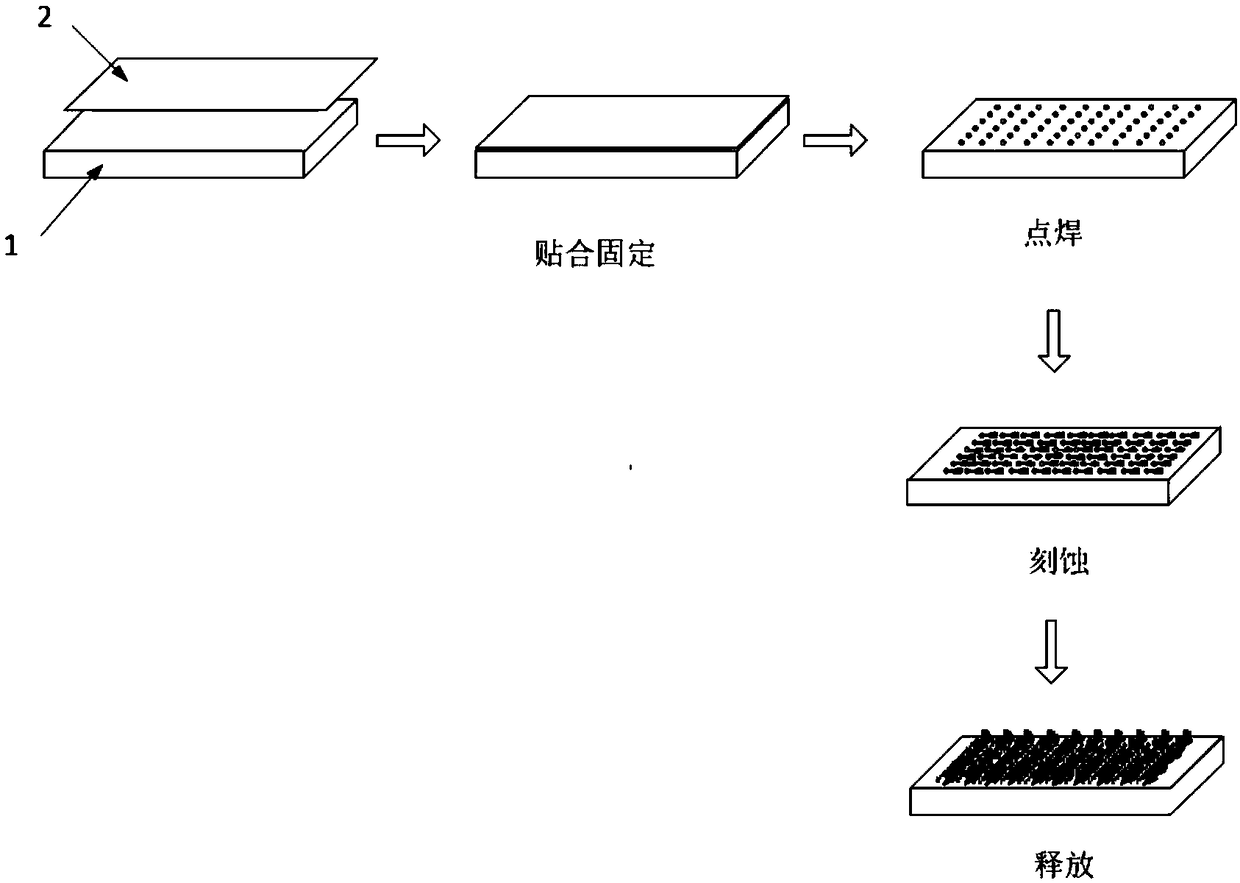

[0028] Such as figure 1 As shown, the invention provides a method for laser direct etching of metal to prepare dry bonded structure surface, specifically comprising the following steps:

[0029] (1) Material preparation: the materials include metal substrate 1 and metal foil 2; the materials of metal substrate 1 and metal foil 2 are stainless steel, copper alloy or aluminum alloy, etc. (the two can be made of different materials); the metal substrate is required The surface roughness Ra values of 1 and metal foil 2 are both less than 3.2 μm, the thickness of metal substrate 1 is greater than 1 mm, and the thickness range of metal foil 2 is 0.002 mm to 0.2 mm; metal foil 2 is required to be flexible, and the surface shape of metal substrate 1 is The expandable surface, that is, the metal foil 2 can fit and cover the pattern area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com