Compound brazing material for brazing quartz short fiber enhanced silicon dioxide composite material and Invar alloys as well as preparation method thereof

A short fiber reinforced, silica technology, used in welding/cutting media/materials, welding equipment, metal processing equipment, etc., can solve problems such as large brittle compounds, achieve suitable melting point, improve microstructure, and improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

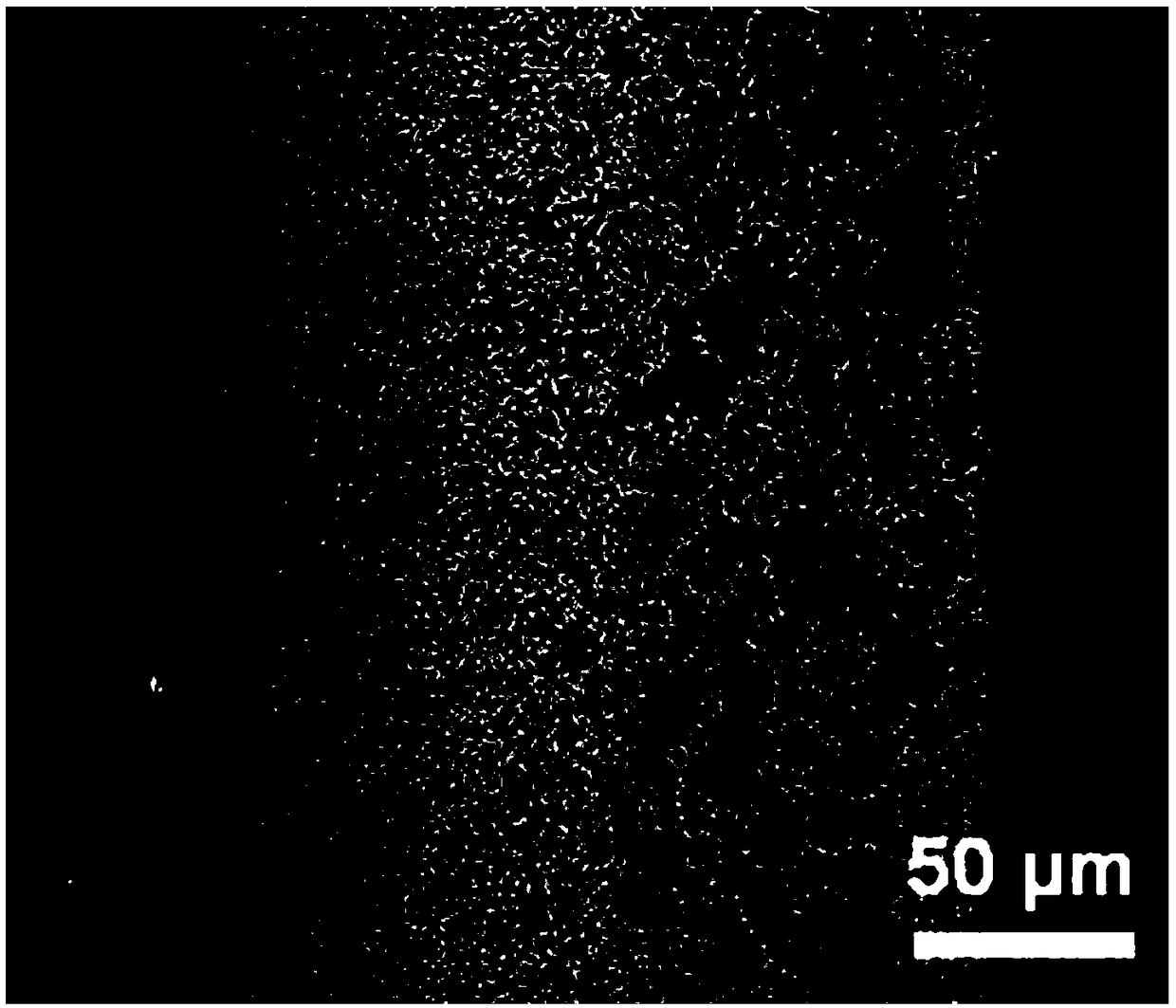

[0021] Specific embodiment one: the present embodiment is used for brazing quartz short fiber reinforced silica composite material and Invar alloy composite solder is made of Cu powder, few-layer graphene and TiH 2 composition.

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is different from Embodiment 1 in that: the purity of the Cu powder is 99.0%-99.9%, and the particle size of the Cu powder is 300 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the TiH 2 The purity is more than 99%, TiH 2 The particle size is 48-52μm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com