Preparation method of porous carbon based electrothermal phase change composite

A composite phase change material and phase change material technology, which is applied in the field of preparation of porous carbon-based electrothermal composite phase change materials, can solve problems such as unfavorable packaging phase change core materials, hinder electron transmission, reduce electrical conductivity, etc., and achieve electrothermal conversion Excellent performance, good cycle stability, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0023] (1) Preparation of carbon nanotubes through porous carbon support materials:

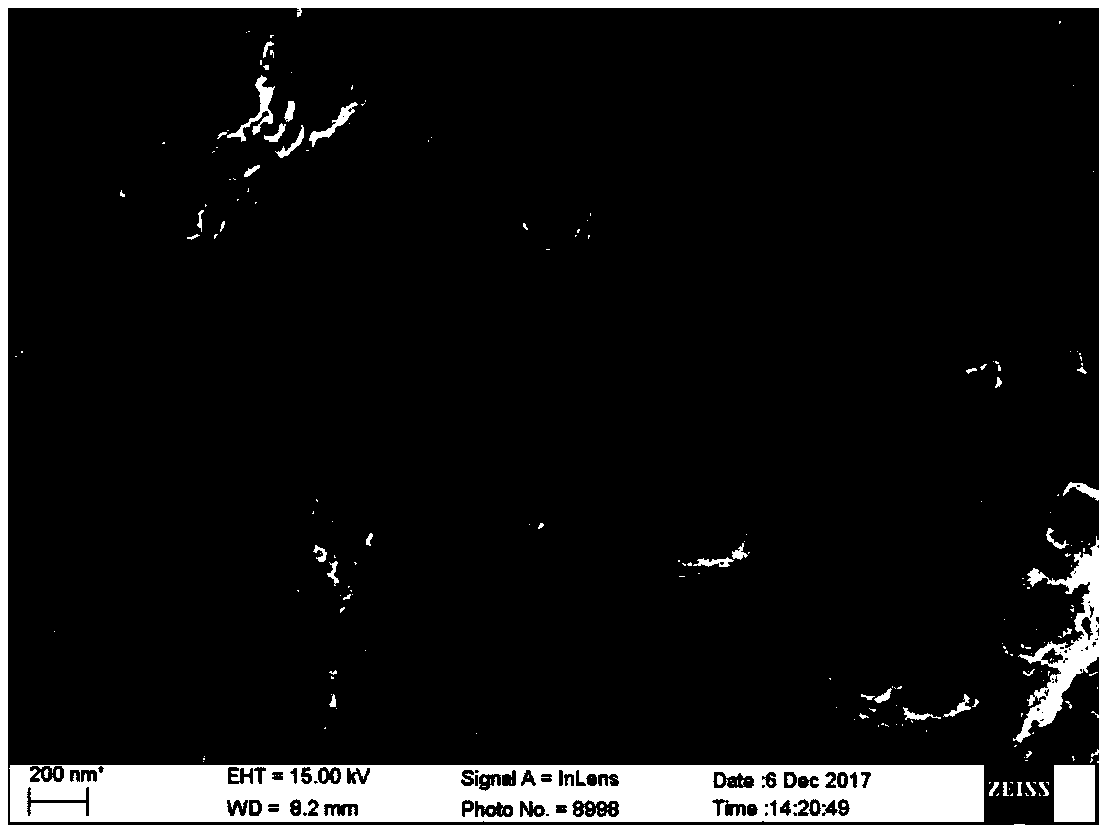

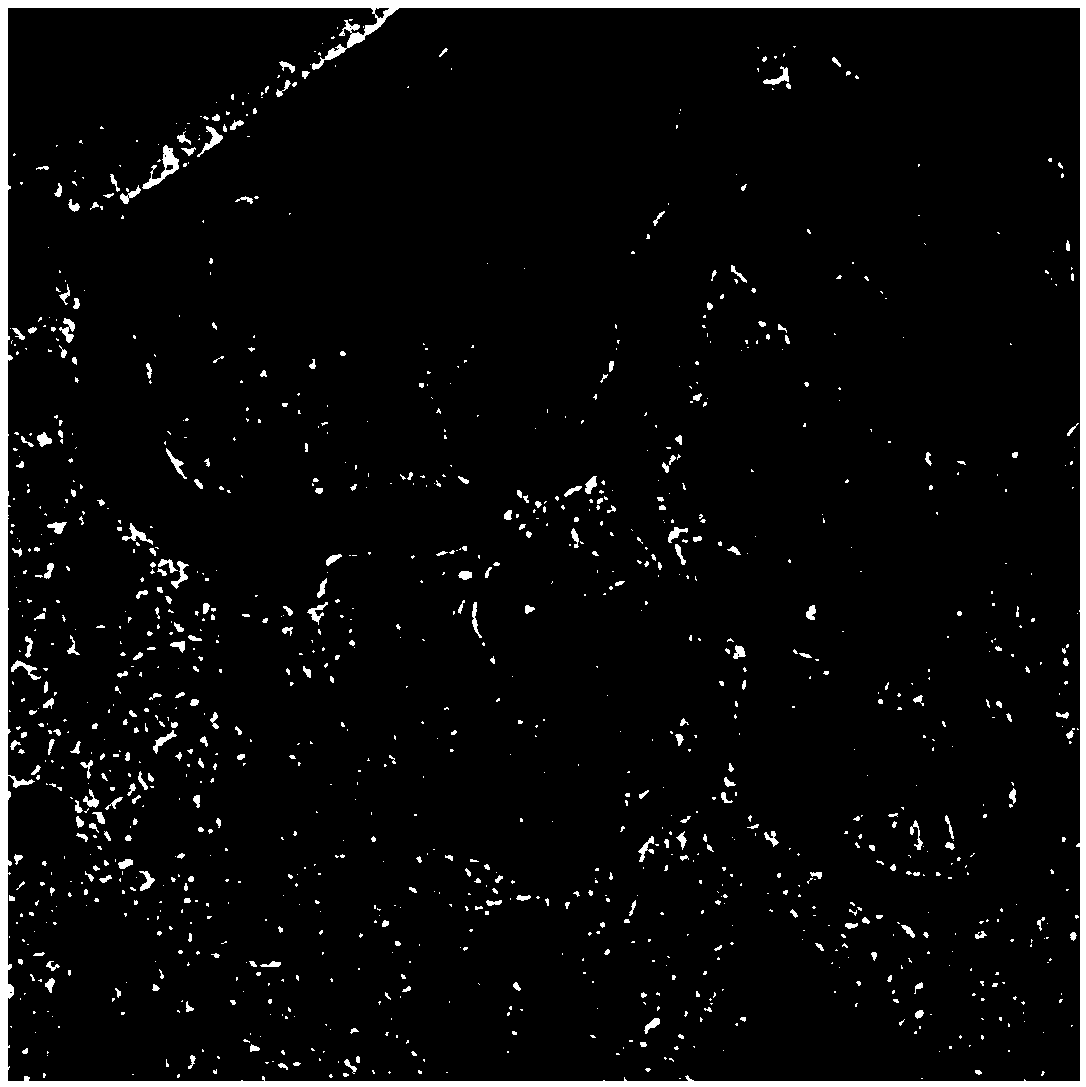

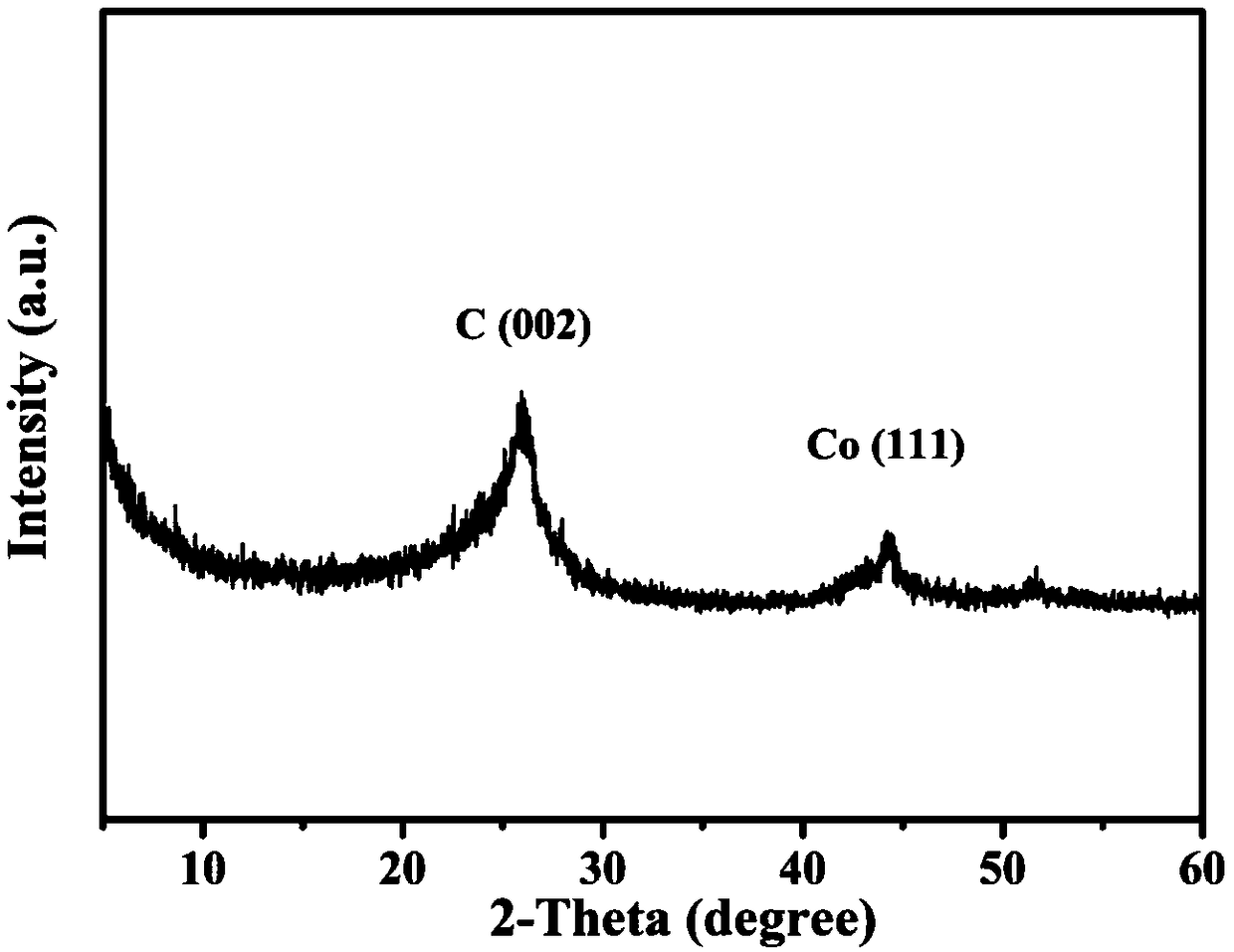

[0024] 2.91 g of cobalt nitrate hexahydrate and 3.28 g of dimethylimidazole were dispersed in 250 ml of methanol solvent. After stirring at room temperature for 24 h, the metal-organic framework ZIF-67 was obtained. 1.0 g of ZIF-67 was dispersed into 500 ml of a DMF solvent containing 3.36 g of zinc nitrate hexahydrate and 1.14 g of 2-aminoterephthalic acid. Stir at room temperature for 12 h, filter and wash with DMF three times, and dry at 80° C. for 24 h. The dried product was subjected to H 2 / Ar atmosphere at a rate of 2 °C / min to 1000 °C, and kept at this temperature for 8 hours, and then cooled to room temperature at a rate of 5 °C / min to obtain a porous carbon support material with carbon nanotubes interspersed.

[0025] (2) Preparation of composite phase change materials:

[0026] 0.25 g of the carbon nanotubes prepared above were evacuated through the porous carbon support materi...

Embodiment example 2

[0028] (1) Preparation of carbon nanotubes through porous carbon support materials:

[0029] 2.97 g of nickel nitrate hexahydrate and 3.28 g of dimethylimidazole were dispersed in 400 ml of methanol solvent. Stirring at 140°C for 24h gave the metal-organic framework Ni-ZIF. 1.0 g of Ni-ZIF was dispersed into 500 ml of DMF solvent containing 3.36 g of zinc nitrate hexahydrate and 1.14 g of 2-methylimidazole. Stir at room temperature for 12 h, filter and wash with DMF three times, and dry at 80° C. for 24 h. The dried product was subjected to H 2 / Ar atmosphere at a rate of 2 °C / min to 1000 °C, and kept at this temperature for 8 hours, and then cooled to room temperature at a rate of 5 °C / min to obtain a porous carbon support material with carbon nanotubes interspersed.

[0030] (2) Preparation of composite phase change materials:

[0031]0.30 g of the carbon nanotubes prepared above were evacuated through the porous carbon support material at 120° C. for 8 hours to complete...

Embodiment example 3

[0033] (1) Preparation of carbon nanotubes through porous carbon support materials:

[0034] Disperse 2.78g of ferrous sulfate heptahydrate and 3.28g of dimethylimidazole into 200ml of methanol solvent. After stirring at room temperature for 24 h, the metal-organic framework Fe-ZIF was obtained. 1.0 g of Fe-ZIF was dispersed into 500 ml of DMF solvent containing 3.36 g of zinc nitrate hexahydrate and 1.14 g of 2-methylimidazole. Stir at room temperature for 12 h, filter and wash with DMF three times, and dry at 80° C. for 24 h. The dried product was subjected to H 2 / Ar atmosphere at a rate of 2 °C / min to 1000 °C, and kept at this temperature for 8 hours, and then cooled to room temperature at a rate of 5 °C / min to obtain a porous carbon support material with carbon nanotubes interspersed.

[0035] (2) Preparation of composite phase change materials:

[0036] 0.20 g of the carbon nanotubes prepared above were evacuated through the porous carbon support material at 120° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com