Immobilized bactericide capable of realizing in-situ restoration of polluted sediment and preparation method and application thereof

A technology for in-situ restoration and sedimentation, applied to the preparation of the above materials, immobilized bacterial agents for in-situ restoration of contaminated sediments, and the application of the above-mentioned materials in the field of in-situ restoration of contaminated sediments to speed up the reaction rate , Improve the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

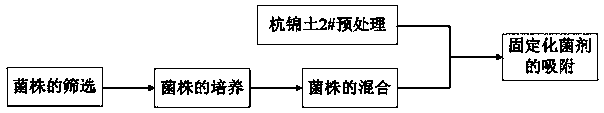

[0035] The preparation method of immobilized bacterial agent of the present invention, comprises the steps:

[0036] 1) Carry out pretreatment of Hangjin soil 2#: coarsely crush Hangjin soil 2# with a mortar, grind and directly pass through a 100-mesh sieve, and use 2.5mol / L H at a ratio of 1:10 (mass: volume) 2 SO 4 Acidify at 90°C for 2 hours, then add 5mol / L NaOH solution to adjust the pH value to 7.5, centrifuge the mud-water mixture, discard the supernatant, wash with pure water for 3-4 times, dry at 90°C, and put it in a horse After being fired at a high temperature of 750°C for 3 hours in a Furnace, it is ready for use, and finally a particle filler with a particle size of less than 0.15mm is obtained.

[0037] 2) Screening of bacterial strains: the microorganisms screened include Geobacter sulfurreducens strain DL1, ATCC52573), Geobacter metallireducens (ATCC53774), Shewanella oneidensis strain MR-1, ATCC700500.

[0038] 3) Purification and cultivation of strains: in...

Embodiment 1

[0046] 1) Preparation of Hangjin soil 2# loading matrix

[0047] The purchased Hangjin soil 2# is coarsely crushed with a mortar, ground and passed through a 100-mesh sieve, and 200g of the ground Hangjin soil 2# is weighed, and 2000ml of 2.5mol / L H 2 SO 4 , acidified in a water bath at 90°C for 2h, and then added 5mol / L NaOH solution to adjust the pH value to 7.5. Pour the mixed solution into a centrifuge tube, centrifuge at 8000rpm for 10min, pour off the supernatant, wash with pure water and centrifuge again, repeat 3-4 times. The precipitate was dried in an oven at 90°C for 2 hours, and then placed in a muffle furnace for 3 hours at a high temperature of 750°C to obtain a particle filler with a particle size of less than 0.15mm in mass of about 190g.

[0048] 2) Screening of strains

[0049] In this example, three kinds of bacteria capable of using iron oxides and humic substances as electron acceptors were screened out from more than 30 extracellular electricity-produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com