Multifunctional long fiber fabric

A filament cloth, multi-functional technology, applied in non-woven fabrics, knitting, textiles, etc., can solve the problems of large influence on tensile strength and tensile modulus, low extensibility, etc., to reduce secondary damage, strengthen The effect of shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

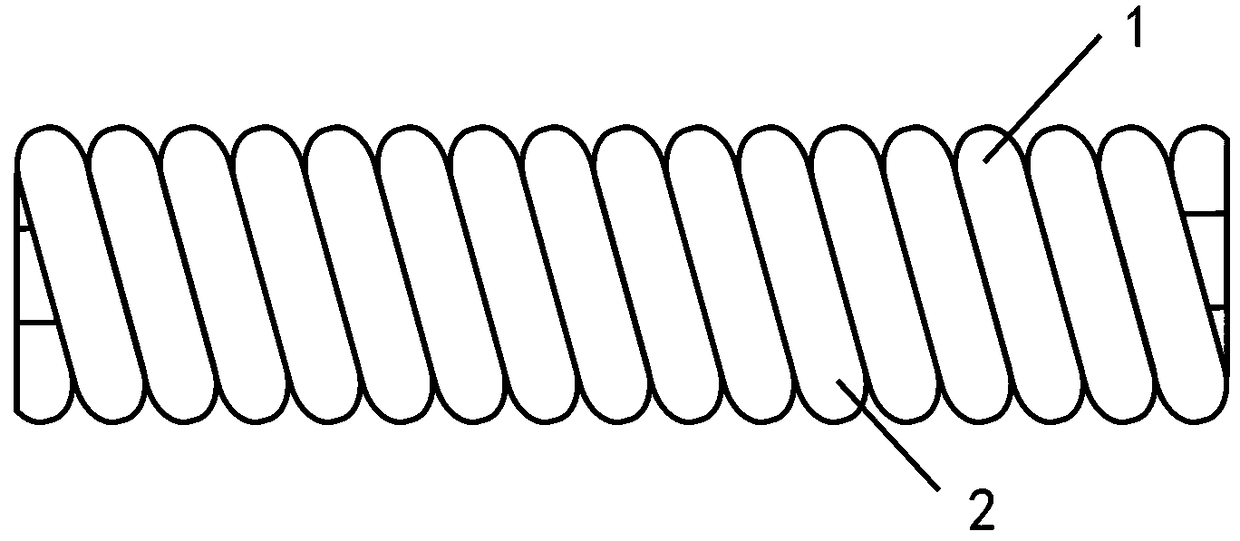

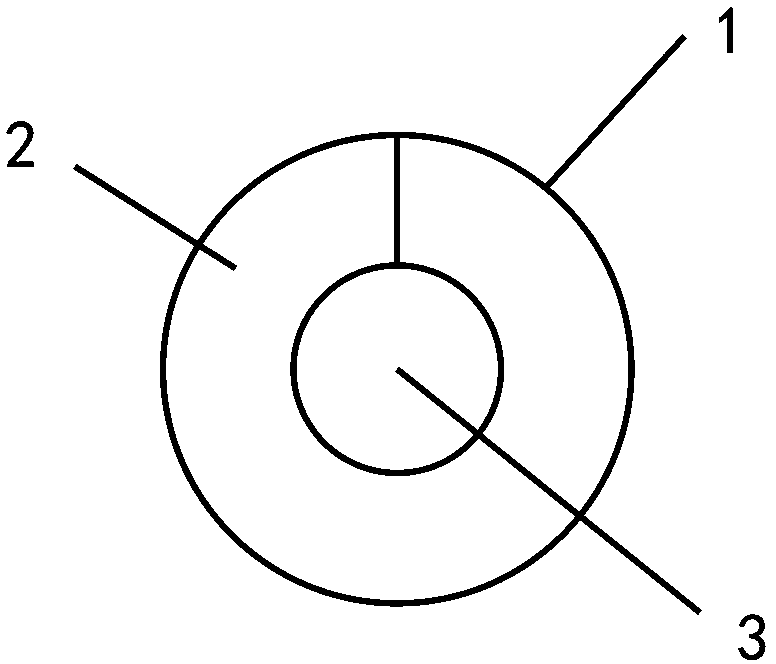

[0030] Multifunctional filament fabrics include non-woven fabrics and their prepregs, interwoven fabrics and their prepregs, warp-knitted fabrics and their prepregs using needle stitching; non-woven fabrics include 0°, -45°, 45° , the unidirectional yarn layer 5 of 90 ° direction, also can adopt the single item yarn layer 5 of any number of layers to be processed into cloth, and the unidirectional yarn layer 5 is closely arranged by any layer of several single filaments 6 or filament bundles, according to The ratio is placed into the spiral thread 1, and the spiral thread 1 is formed by a single filament 6 or a filament bundle, or a single wire or a single wire bundle, and spirals along the outer circumference of the core material 4 axially. Wrapping 2 into a winding layer, the winding layer is Z-direction or S-direction, and the core material 4 can also be wrapped around the first layer and then reversely wrap the second layer and more layers; so that the cloth can For long-d...

Embodiment 2

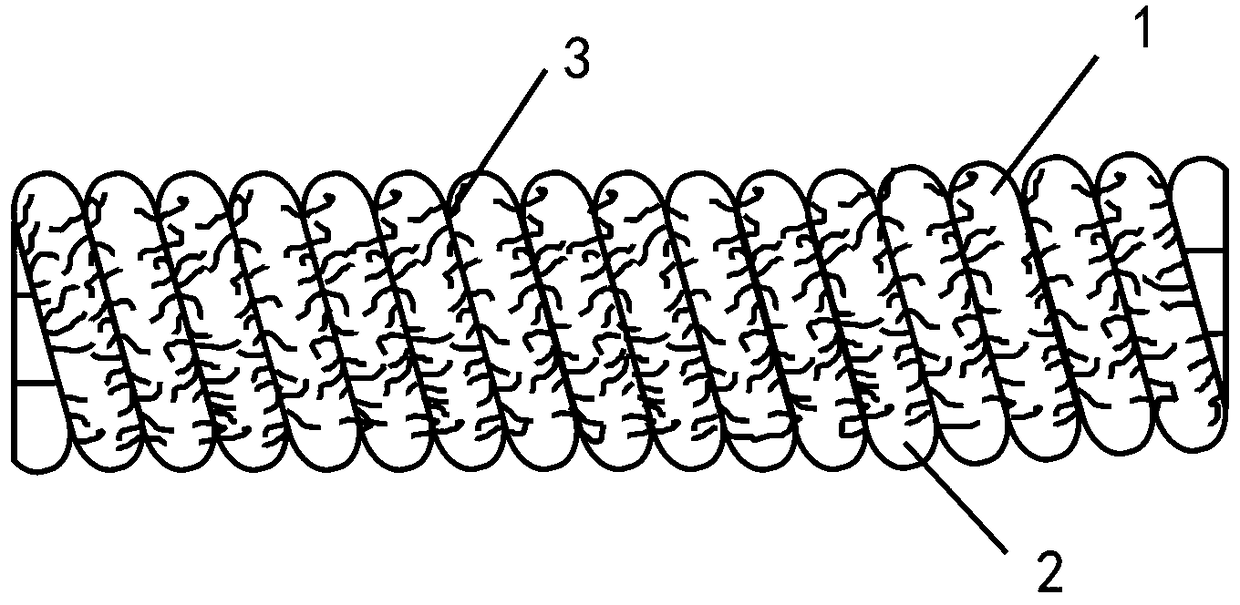

[0033] The outer layer of the spiral thread 1 winding layer, the spiral shape is formed by wrapping around a circle, and chopped strands 3 can be placed between the circles. One end of the chopped strands 3 extends into the winding layer, and the other end extends into the winding layer. Out of the winding layer, the protruding part is the same as that of another silk layer and extends into each other. After the subsequent processing of the composite material base material is cured, the interlayer fusion is strengthened. The core material 4 of the spiral thread 1 can be the same Homogeneous materials or non-homogeneous materials can also be used to mix different materials, and elastic rubber strips 7 can also be used.

Embodiment 3

[0035] The interwoven fabric can be arranged by placing either or both of the spiral thread strips 1 or the elastic rubber strips 7 in proportion in the warp and weft layers, and weaving into various filament interwoven fabrics or single warp filaments. Cloth, and then further processed into prepreg; needle seam warp knitted fabric can place one or both of the spiral thread strips 1 or elastic rubber strips 7 in any unidirectional thread layer 5 in proportion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com