Natural gas oxygen-enriched combustion and transcritical CO2 circulation coupling power generation system

An oxygen-enriched combustion and power generation system technology, which is applied in the direction of machines/engines, gas turbine devices, steam engine devices, etc., can solve the problems of waste of cold energy and low power generation efficiency, and achieve simple system devices, improve power generation efficiency, and reduce system power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

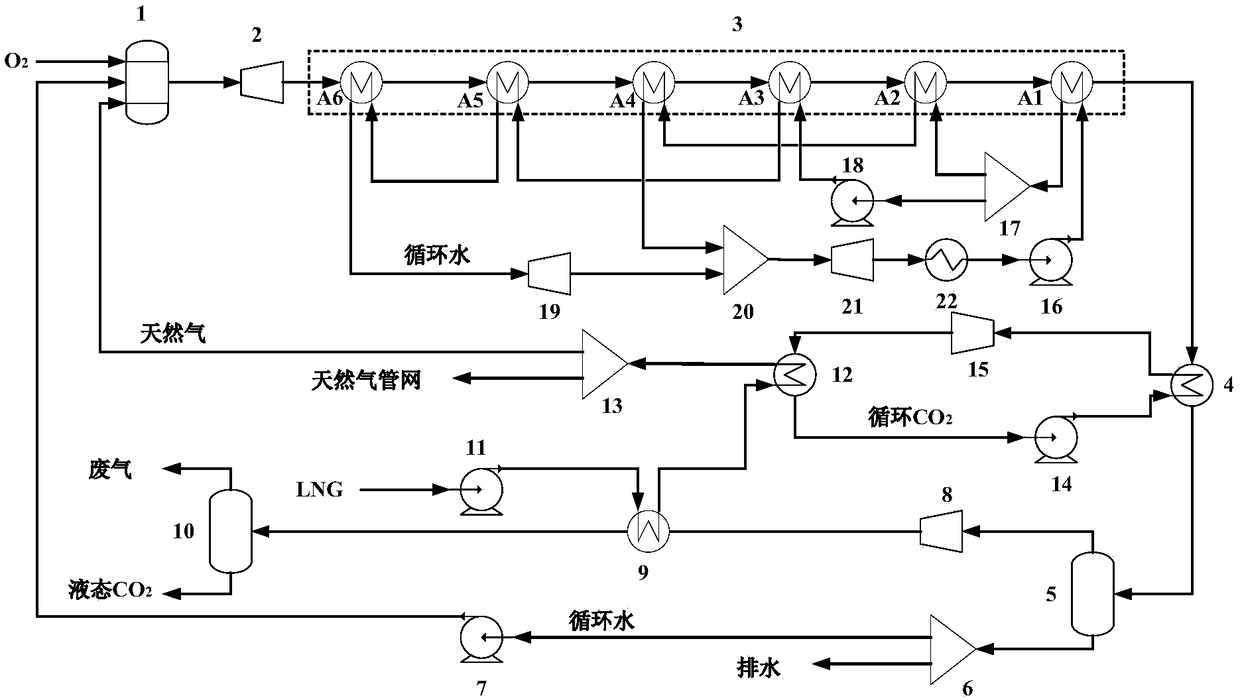

[0052] A combined cycle based on oxyfuel combustion of natural gas and transcritical CO 2 Cyclic coupling power system, its process flow is as follows figure 1 As shown, the specific process is as follows:

[0053] (1) High pressure O 2 / H 2 O combustion gas turbine cycle

[0054] High pressure O with a molar concentration higher than 95% 2 It is mixed with the circulating water separated from the combustion flue gas and the high-pressure natural gas used for combustion, and then enters the combustion chamber 1 for combustion. The combustion pressure is 3.0-9.0 MPa, and the high-temperature and high-pressure flue gas with a temperature of 1250-1400 ° C is generated. The flue gas enters the gas turbine 2 to expand and perform work, the pressure drops to slightly higher than the ambient pressure, and the temperature drops to 600-700°C accordingly. The high-temperature exhaust gas from the gas turbine enters the waste heat boiler 3 to provide heat for the steam Rankine cycle...

Embodiment 2

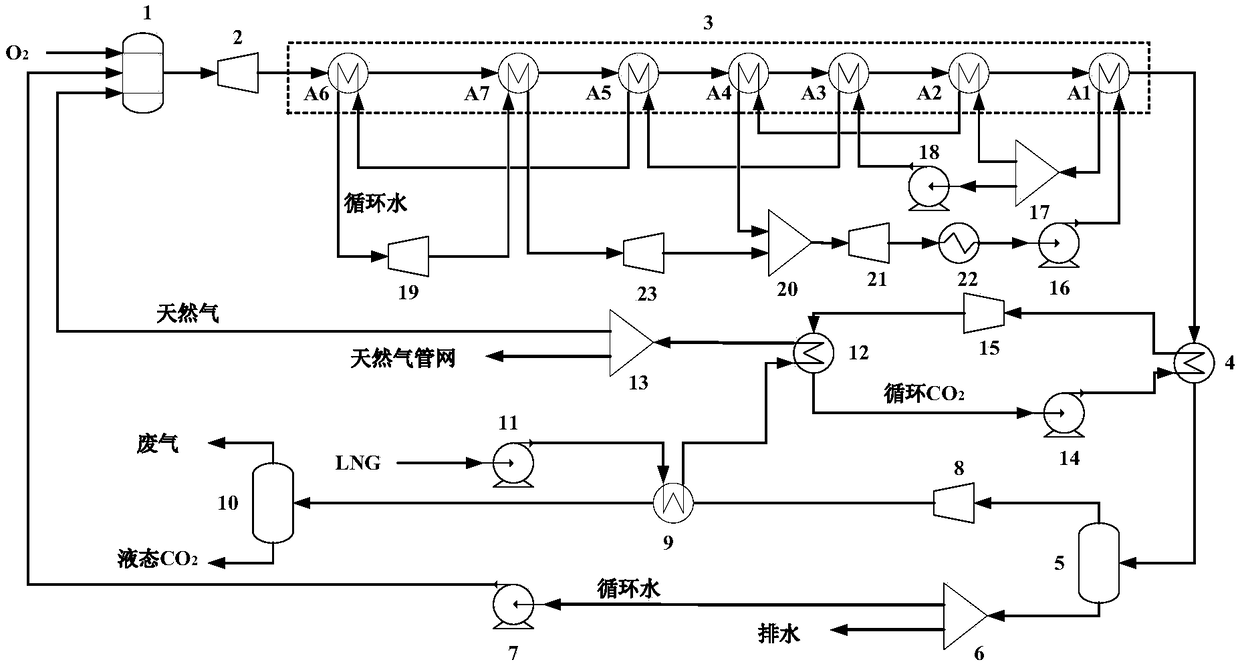

[0064] A combined cycle based on oxyfuel combustion of natural gas and transcritical CO 2 Cyclic coupling power system, its process flow is as follows figure 2 shown. This embodiment is different from Embodiment 1 in that, on the basis of the dual-pressure no-reheat steam Rankine cycle of the first embodiment 1, steam reheating is added. Compared with the system in Embodiment 1, this system has a reheater A7 and a reheater turbine 23 as additional equipment. The high-pressure superheated steam generated in the high-pressure superheater A6 expands and does work in the high-pressure steam turbine 19. The exhaust steam is first reheated to 550°C by the reheater A7, and then enters the reheater turbine 23 to expand and perform work. The exhaust steam and the low-pressure superheated steam It is mixed in the confluencer 20, and is input into the low-pressure steam turbine 21 to do work, and the exhaust gas of the low-pressure steam turbine 21 enters the condenser 22 to be conden...

Embodiment 3

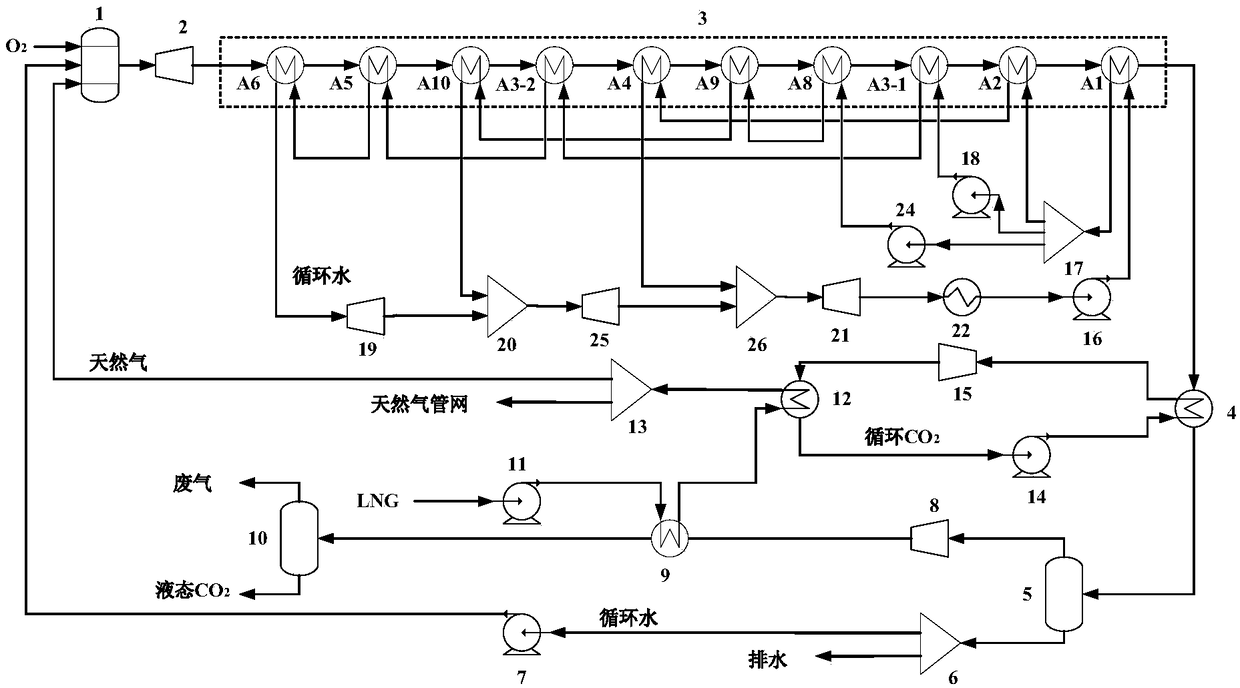

[0067] A combined cycle based on oxyfuel combustion of natural gas and transcritical CO 2 Cyclic coupling power system, its process flow is as follows image 3 shown. This embodiment differs from Embodiment 1 in that, on the basis of the dual-pressure non-reheating steam Rankine cycle, the intermediate pressure stage is added. Compared with the system in Example 1, the added equipment of this system is a medium pressure pump 24, a medium pressure steam turbine 25, and a confluencer 26. In addition, the high pressure economizer is divided into two, namely, the first stage of high pressure economizer Device A3-1 and high pressure low secondary economizer A3-2. The specific process is as follows: the circulating water first enters the low-pressure pump 16 and is pressurized to a low-pressure pressure of 0.3-0.5MPa, then is preheated by the low-pressure economizer A1, and enters the water separator 17 to be divided into three strands, and one strand enters the low-pressure evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com