A Realization Method of Caseless Automatic Weapon Using Liquid Propellant

A technology for automatic weapons and propellants, applied in weapon accessories, ammunition supply, percussion/trigger mechanism, etc., can solve the problems of affecting shooting accuracy, reducing the utilization efficiency of gunpowder, difficult to use gunpowder gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation cases.

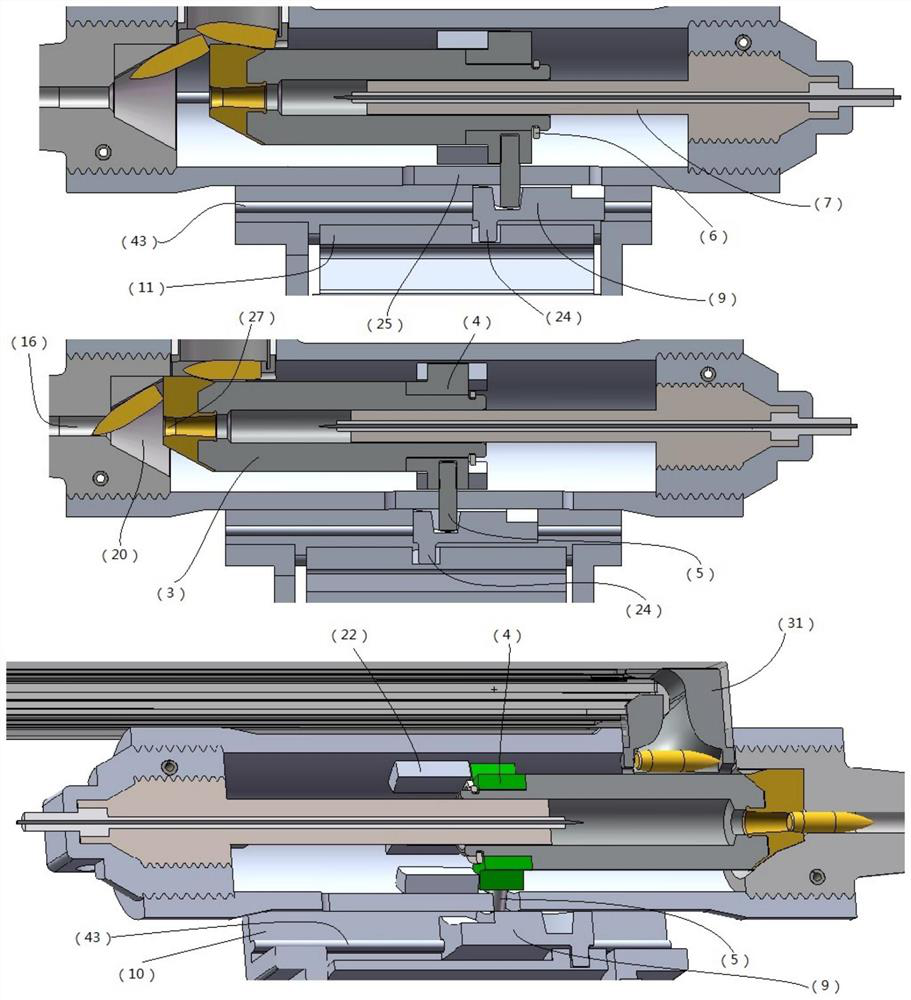

[0072] The main implementation process of the method provided by the present invention comprises:

[0073] Taking the relevant parameters of NATO 5.56mm caliber ammunition as a reference, this implementation process gives a special design example of a 5.56mm bullpup assault rifle with a heavy barrel length of 508mm (20 inches). Automatic shooting meets the needs of most field and street battles, and the bullpup structure is also suitable for mechanized infantry to use in narrow vehicles.

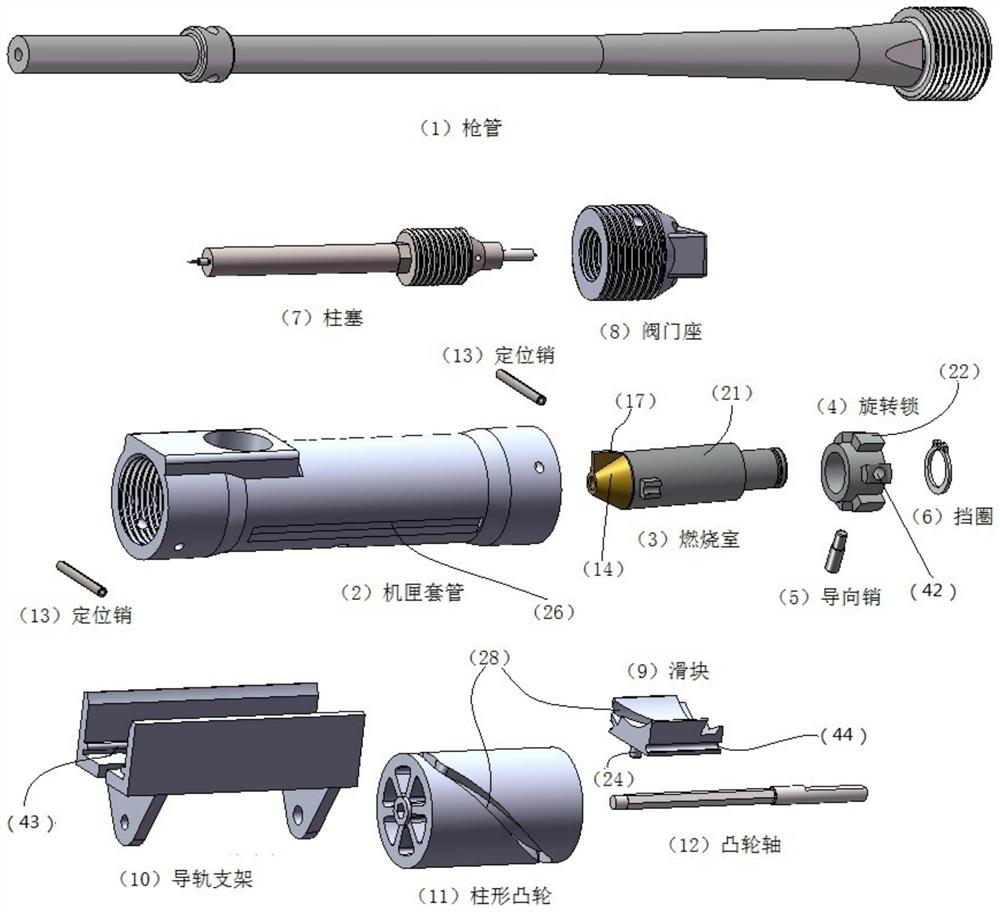

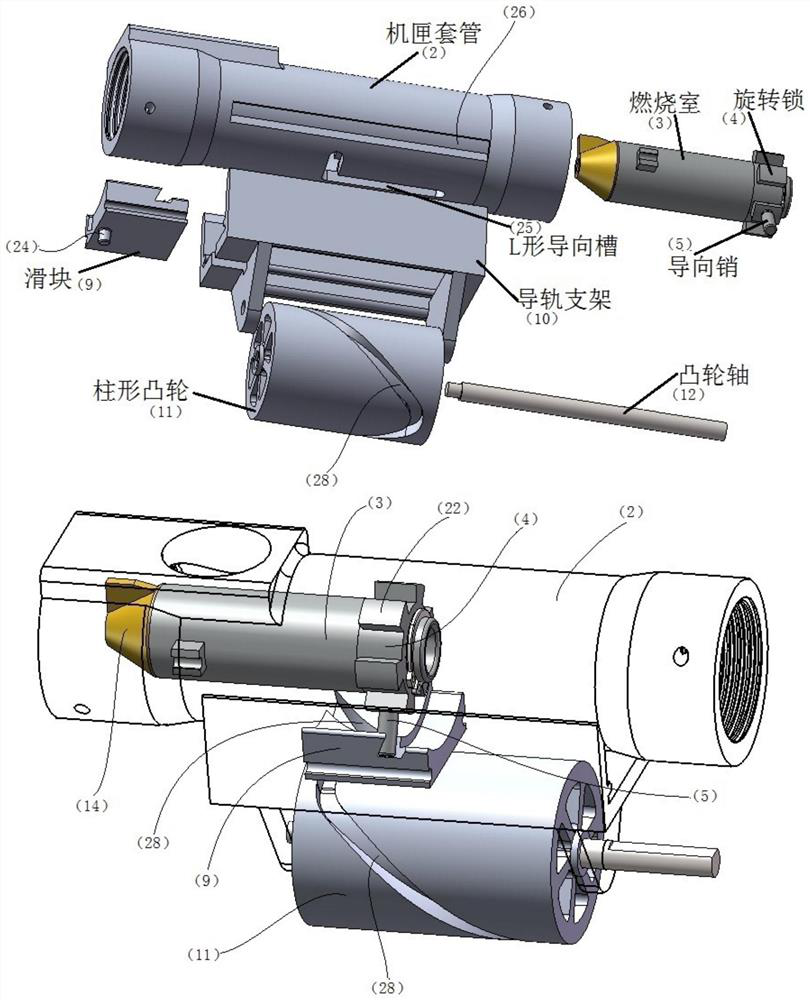

[0074] The main mechanical parts of the whole gun, such as figure 1 As shown, it mainly includes the following parts: ⑴ barrel, ⑵ receiver sleeve, ⑶ combustion chamber, ⑷ rotation lock, ⑸ guide pin, ⑹ retaining ring, ⑺ plunger, ⑻ valve seat, ⑼ slider,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com