A kind of preparation method of veterinary suspension injection

A technology for suspending injection and liquid, which is applied in the field of preparation of veterinary suspension injection, can solve the problems of sensitivity, animal stress, and drug deposition is not easy to shake, and achieves good photostability and high sedimentation volume ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

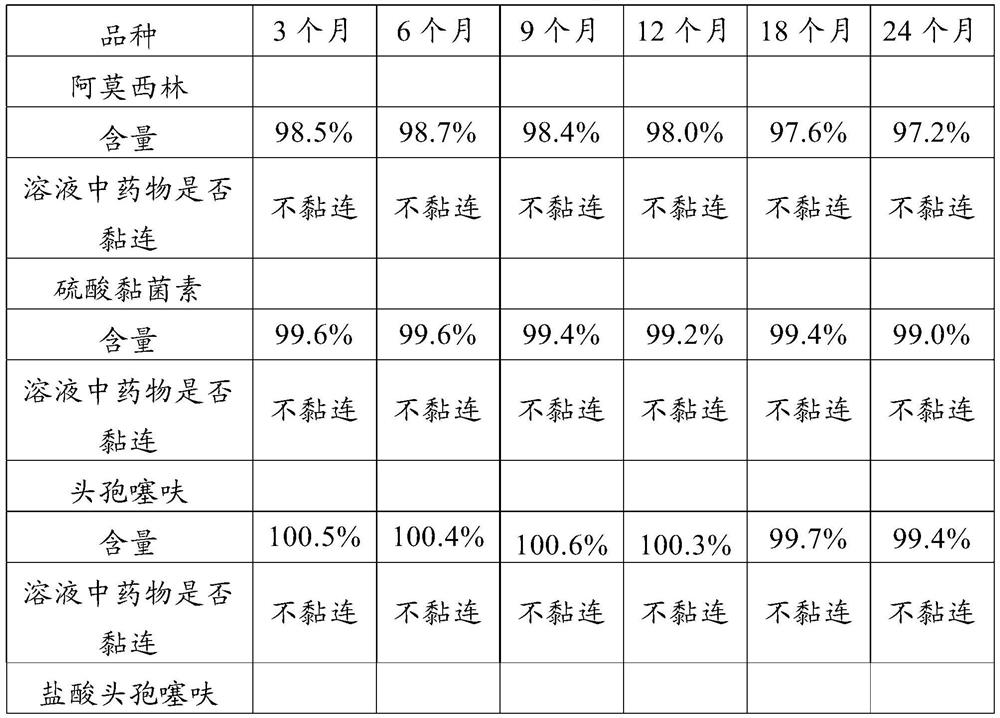

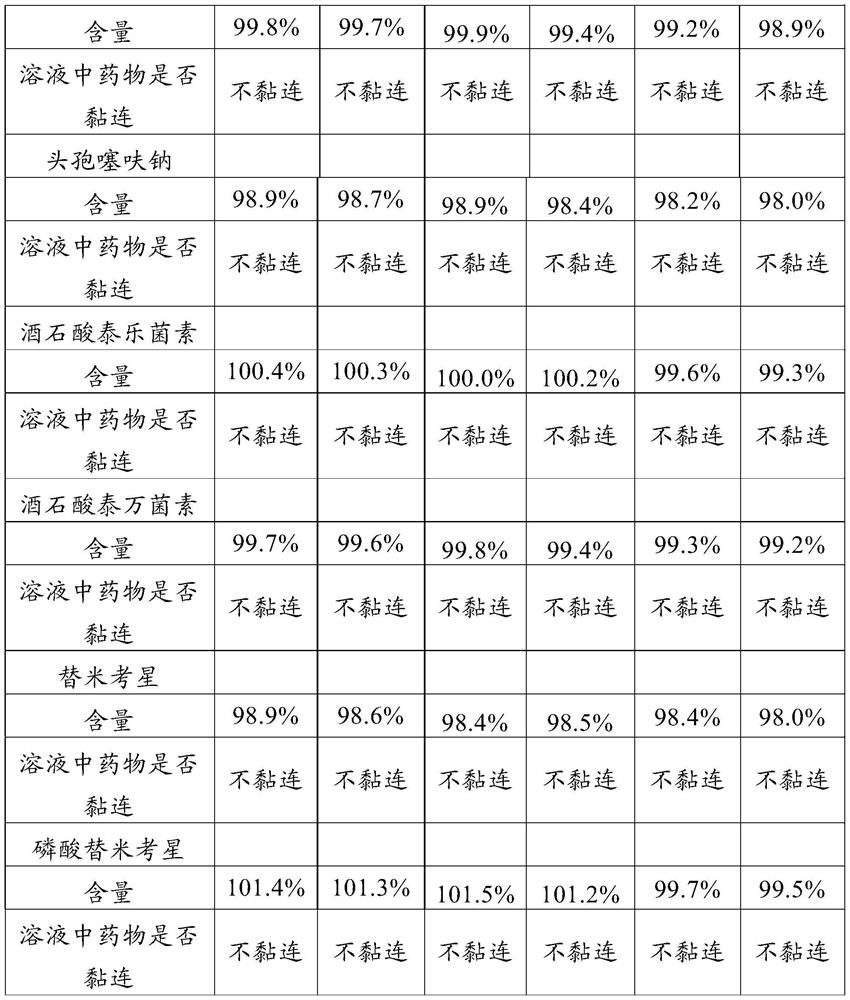

Examples

Embodiment 1

[0017] Embodiment 1, amoxicillin, colistin sulfate, ceftiofur, ceftiofur hydrochloride, ceftiofur sodium, tylosin tartrate, tyvanectin tartrate, tilmicosin, tilmicosin phosphate raw materials 5kg (raw materials are calculated as dry products, raw salt is calculated as dry products and raw materials); silicon dioxide 0.25kg; PEG-400 5kg; GTCC several.

[0018] Concrete preparation steps:

[0019] 1. Superfine pulverize the above raw materials so that the particle size is lower than 15um and take 5kg each for later use;

[0020] 2. Superfinely pulverize the silica to make the particle size less than 15um and take 0.25kg for later use;

[0021] 3. Take 5kg of PEG-400 and 80kg of GTCC, put it into the emulsification pot and stir to make it evenly mixed.

[0022] 4. Take 0.25kg of silicon dioxide and 5kg of amoxicillin into the emulsification pot and stir, then use GTCC to set the volume to 100L.

[0023] 5. Turn on the backflow and high-speed shearing device, control the liquid...

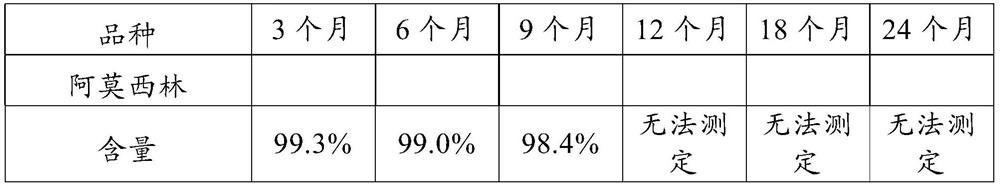

Embodiment 2

[0025] Example 2, Amoxicillin, colistin sulfate, ceftiofur, ceftiofur hydrochloride, ceftiofur sodium, tylosin tartrate, tyvanectin tartrate, tilmicosin, tilmicosin phosphate raw materials 5kg (the raw materials are calculated as dry products, and the raw salt is calculated as dry products and raw materials); silicon dioxide 0.25kg; some soybean oil.

[0026] Concrete preparation steps:

[0027] 1. Superfine pulverize the above raw materials so that the particle size is lower than 15um and take 5kg each for later use;

[0028] 2. Take 80kg of soybean oil and put it into the emulsification pot.

[0029] 3. Take 5kg of amoxicillin, put it into the emulsification pot and stir, then use soybean oil to make the volume to 100L.

[0030] 4. Turn on the backflow and high-speed shearing device, control the liquid temperature below 40 degrees, and shear for 20 minutes.

[0031] Repeat the above operations to obtain amoxicillin, colistin sulfate, ceftiofur, ceftiofur hydrochloride, ce...

Embodiment 3

[0032] Example 3, Amoxicillin, colistin sulfate, ceftiofur, ceftiofur hydrochloride, ceftiofur sodium, tylosin tartrate, tyvanectin tartrate, tilmicosin, tilmicosin phosphate raw materials 5kg (the raw materials are calculated as dry products, and the raw salt is calculated as dry products and raw materials); silicon dioxide 0.25kg; some white oil.

[0033] Concrete preparation steps:

[0034] 1. Superfine pulverize the above raw materials so that the particle size is lower than 15um and take 5kg each for later use;

[0035] 2. Take 80kg of white oil and put it into the emulsification pot.

[0036] 3. Take 5kg of amoxicillin, put it into the emulsification pot and stir it, then use white oil to make the volume to 100L.

[0037] 4. Turn on the backflow and high-speed shearing device, control the liquid temperature below 40 degrees, and shear for 20 minutes.

[0038] Repeat the above operations to obtain amoxicillin, colistin sulfate, ceftiofur, ceftiofur hydrochloride, cefti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com