Arc fuse additive manufacturing method for porous materials

A technology of additive manufacturing and porous materials, applied in the field of additive manufacturing, can solve the problems of high printing accuracy, long printing time per unit price, and low efficiency of the manufacturing process, and achieve the effect of high-efficiency preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Adopting the method of the present invention to carry out arc fuse additive manufacturing of porous materials to carbon steel, the preparation method comprises the following steps:

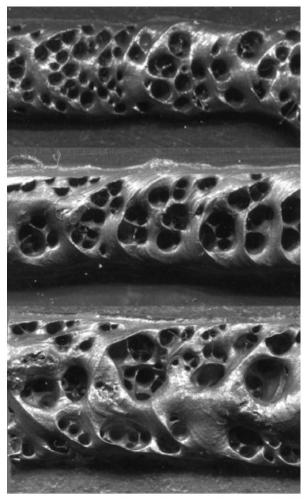

[0033] Gas metal shielded welding torch is used for fuse additive accumulation, in which the welding torch is placed vertically, the dry elongation is 15mm, and the diameter of welding wire is 1.2mm; the auxiliary arc adopts tungsten argon arc welding torch, and the angle between the welding torch and the melting electrode is 45°, and the current 100A, 0.05mm pure iron foil is used to separate the layers; by adjusting the current of the gas metal arc welding torch and the speed of the torch, porous materials with different hole sizes can be obtained, such as figure 1 shown.

Embodiment 2

[0035] Using the method of the present invention to carry out arc fuse additive manufacturing of porous materials on 6061 aluminum alloy, the preparation method comprises the following steps:

[0036] Use MIGA welding torch for fuse additive accumulation, where the welding torch is placed vertically, the dry elongation is 12mm, the welding wire diameter is 1.2mm, and the layers are separated by 0.02mm pure aluminum foil; the atomizing water vapor device is placed at the front of the welding torch, so that the arc is located In the range of water vapor, aluminum alloy porous materials with different pore sizes can be obtained by adjusting the current of the gas metal arc welding torch and the walking speed of the torch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com