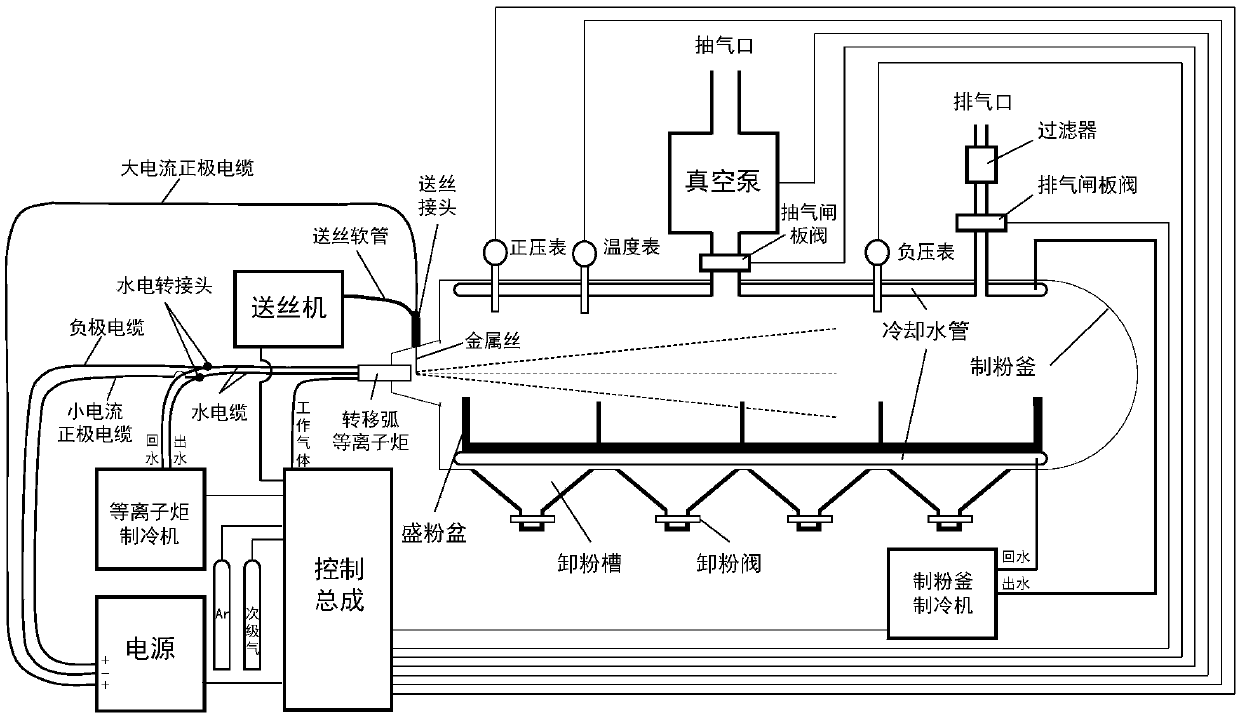

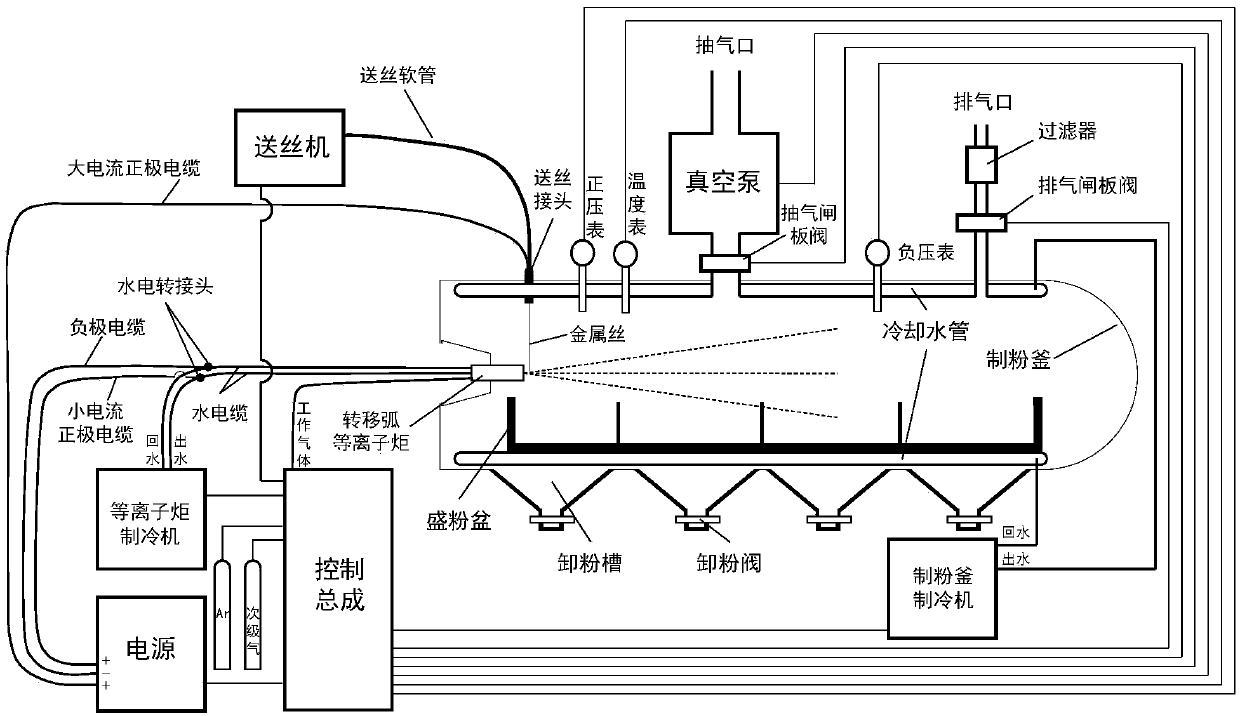

Device and method for preparing metal spherical powder by utilizing metal wire material

A spherical powder and metal powder technology, which is applied in the field of metal spherical powder preparation, can solve the problems of large particle size of spherical powder, multi-sphericity of hollow spheres, etc., and achieve the effect of less satellite spheres, high solid rate and high powder making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment one (adopting argon alone as working gas)

[0076] The plasma torch adopts high-energy supersonic plasma torch (spray gun), and uses metal titanium wire to prepare metal titanium spherical powder. The specific working parameters are as follows:

[0077] Distance between metal titanium wire and nozzle: 5mm,

[0078] Argon flow: 120L / min,

[0079] Non-transferred arc current: 80A,

[0080] Transfer arc current: 400A,

[0081] Working voltage: 130V,

[0082] Titanium wire diameter: 2mm,

[0083] The minimum negative pressure in the powder making kettle: 10mba,

[0084] The maximum positive pressure of the powder making kettle during work: 0.15MPa;

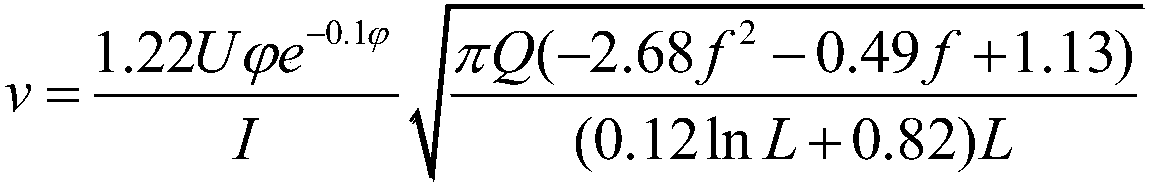

[0085] Control the wire feeding speed of the metal wire to meet:

[0086]

[0087] In the titanium spherical powder obtained in Example 1, the proportion of spherical powder with a small particle size of 15-53 μm is more than 50%; the spherical powder is basically solid, and there are few satellites; the mi...

Embodiment 2

[0088] Embodiment two (adopting the mixed gas of argon and helium as working gas)

[0089] The plasma torch adopts high-energy supersonic plasma torch (spray gun), and uses metal titanium wire to prepare metal titanium spherical powder. The specific working parameters are as follows:

[0090] Distance between metal titanium wire and nozzle: 6mm,

[0091] Main gas (argon) flow rate: 140L / min,

[0092] Secondary gas (helium) flow rate: 20L / min

[0093] Non-transferred arc current: 80A,

[0094] Transfer arc current: 400A,

[0095] Working voltage: 140V,

[0096] Titanium wire diameter: 3mm,

[0097] Wire feeding speed: 6.5m / min

[0098] The minimum negative pressure in the powder making kettle: 10mba,

[0099] The maximum positive pressure of the powder making kettle during work: 0.15MPa;

[0100]In the titanium spherical powder obtained in Example 2, the proportion of spherical powder with a small particle size of 15-53 μm is more than 50%; the spherical powder is basic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com