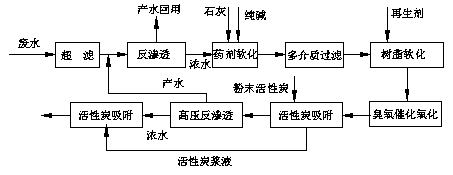

Treatment process for near-zero discharge of industrial wastewater

A treatment process and near-zero discharge technology, applied in water/sewage treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve problems such as incomplete wastewater treatment, affecting human health, and environmental pollution of wastewater. Achieve the effects of saving dosage, prolonging residence time and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The wastewater from a coking plant after three-stage treatment has a COD of 50mg / L and a hardness of 1.5mmol / L. First, it passes through an ultrafiltration system to remove part of the suspended solids and macromolecular colloids. The ultrafiltration effluent has a COD of 30mg / L and a hardness of 1.5mmol. / L, and then enter the reverse osmosis system to reuse the desalted water, the water production rate is 80%, the concentrated water COD is 150mg / L, and the hardness is 7.5mmol / L. / L soda ash, the hardness of the effluent is reduced to 0.8mmol / L, the effluent is filtered by a multi-media to remove suspended solids in the wastewater, and then enters the cation exchange resin softening system, the hardness of the effluent is reduced to 0.04mmol / L, and the effluent enters the ozone catalytic oxidation unit for ozone oxidation The effect is to mineralize part of the organic matter, the ozone catalytic oxidation is filled with KLCO-3 catalyst, the hydraulic retention time is ...

Embodiment 2

[0024] The wastewater from a coal chemical plant after three-stage treatment has a COD of 60mg / L and a hardness of 2mmol / L. First, it passes through an ultrafiltration system to remove part of the suspended solids and macromolecular colloids. The ultrafiltration effluent has a COD of 40mg / L and a hardness of 2mmol / L. , and then enter the reverse osmosis system to reuse the desalted water, the water production rate is 80%, the concentrated water COD is 200mg / L, and the hardness is 10mmol / L. , the hardness of the effluent is reduced to 0.7mmol / L, the effluent is filtered by multimedia to remove the suspended solids in the wastewater, and enters the cation exchange resin softening system, the hardness of the effluent is reduced to 0.04mmol / L, and the effluent enters the ozone catalytic oxidation unit to oxidize some Organic matter mineralization, ozone catalytic oxidation, KLCO-3 catalyst is loaded, the hydraulic retention time is 1.5h, the ozone dosage is 200mg / L, the COD is redu...

Embodiment 3

[0026] The wastewater from a coal chemical plant after three-stage treatment has a COD of 70mg / L and a hardness of 2.5mmol / L. First, the ultrafiltration system removes part of the suspended solids and macromolecular colloids. The ultrafiltration effluent has a COD of 50mg / L and a hardness of 2.5mmol. / L, and then enter the reverse osmosis system to reuse the desalted water, the water production rate is 80%, the concentrated water COD is 250mg / L, and the hardness is 12.5mmol / L. / L soda ash, the hardness of the effluent is reduced to 0.8mmol / L, the effluent is filtered by a multi-media to remove suspended solids in the wastewater, and then enters the cation exchange resin softening system, the hardness of the effluent is reduced to 0.04mmol / L, and the effluent enters the ozone catalytic oxidation unit for ozone oxidation The effect is to mineralize part of the organic matter, ozone catalytic oxidation is loaded with KLCO-3 catalyst, the hydraulic retention time is 2h, the dosage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com