Anti-oxidation layer of conductive fabric and preparation method

A technology of anti-oxidation layer and conductive cloth, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of limited use of conductive cloth, prolong the life of conductive cloth, increase the quality of conductive cloth, and improve the safety of anti-oxidation Anti-oxidation, high-efficiency anti-oxidation, fire-proof and anti-corrosion performance, and the effect of enhancing anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

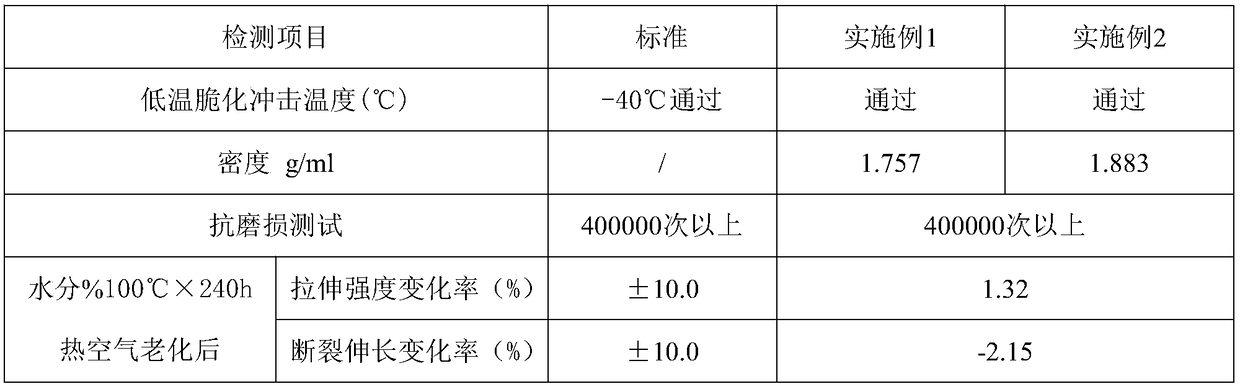

Embodiment 1

[0026] An anti-oxidation layer of a conductive cloth and a preparation method thereof;

[0027] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0028] An anti-oxidation layer of conductive cloth and its preparation method, including the following specific technical solutions: An anti-oxidation layer of conductive cloth and its preparation method are as follows:

[0029] The conductive fabric anti-oxidation layer includes the following components in mass fractions: 2 parts of antioxidant, 1 part of anhydrous calcium chloride, 0.6 parts of maleic rosin, 4 parts of dioctyl phthalate, 25 parts of polyvinyl chloride, 20 parts of polystyrene, 7 parts of 3,4-dimethylpyrazolate, 15 parts of aluminum phosphate, 6 parts of water-based silicone resin, 8 parts of monoglyceride laurate, 6 parts of triethyl phosphate, nano rubber powder 5 parts, 5 parts of ammonium polyphosphate, 6 parts of triphenyl phosphate, 9 parts of t...

Embodiment 2

[0043] An anti-oxidation layer of a conductive cloth and a preparation method thereof;

[0044] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0045] An anti-oxidation layer of conductive cloth and its preparation method, including the following specific technical solutions: An anti-oxidation layer of conductive cloth and its preparation method are as follows:

[0046] The conductive fabric anti-oxidation layer includes the following components in mass fractions: 2 parts of antioxidant, 1.5 parts of anhydrous calcium chloride, 0.6 parts of maleic rosin, 4 parts of dioctyl phthalate, 25 parts of polyvinyl chloride, 20 parts of polystyrene, 11 parts of 3,4-dimethylpyrazolate, 15 parts of aluminum phosphate, 8 parts of water-based silicone resin, 7 parts of monoglyceride laurate, 6 parts of triethyl phosphate, nano rubber powder 7 parts, 4 parts of ammonium polyphosphate, 5 parts of triphenyl phosphate, 12 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com