A kind of reflective thermal film and its preparation method

A thermal film, reflective technology, applied in the direction of film/sheet release coating, film/sheet adhesive, coating, etc., can solve the problem that PE/PET composite film is not easy to tear, and the surface of reflective film is printed. and other problems, to achieve the effect of more aesthetics, easy peeling, and improved convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

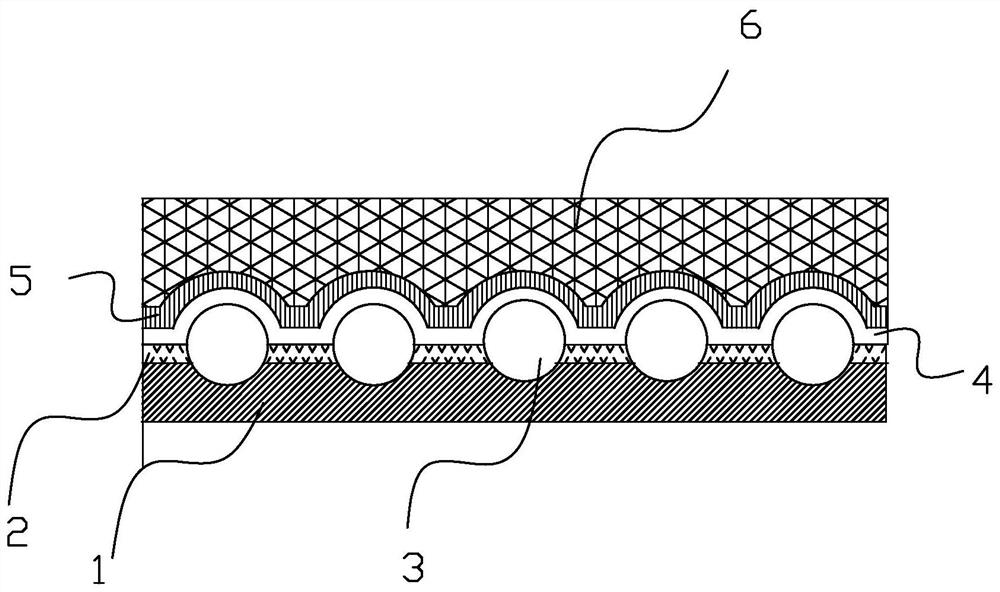

[0026] Such as figure 1 As shown, a reflective thermal film includes a PE / PET composite film 1, a printing layer 2, a glass bead layer 3, an adhesive layer 4, an electroplating layer 5, and a hot-melt adhesive layer 6, which are laminated sequentially from bottom to top. The thickness of PE / PET composite film 1 is 2.0mm, which plays a protective role before the reflective film is hot pasted; the particle size of the glass beads is 400 mesh, and the diffuse reflection effect of the glass beads under this mesh number is good, which is comparable to that of PE / PET The composite film 1 has a large contact area to make it easy to peel off; the adhesive layer 4 uses polyurethane glue with a thickness of 10 μm; the electroplating layer 5 is an aluminum layer with a thickness of 20 nanometers, which plays a reflective role; the hot-melt adhesive layer 6 is a conventional hot-melt adhesive in the market , Play the role of thermocompression bonding. The components of the printing layer...

Embodiment 2

[0035] A reflective thermal film, comprising a PE / PET composite film 1, a printing layer 2, a glass bead layer 3, an adhesive layer 4, an electroplating layer 5, and a hot-melt adhesive layer 6, which are laminated sequentially from bottom to top. PE / PET composite film 1 has a thickness of 1.0 mm; the particle size of the glass beads is 450 mesh; the adhesive layer 4 uses bright silver glue, which can play a reflective effect; The adhesive layer 6 is a conventional hot melt adhesive in the market. The components of the printing layer 2 are made up of the following raw materials in parts by weight: 10 parts of nano silicon dioxide, 10 parts of superfine calcium carbonate, 10 parts of silane coupling agent, 30 parts of polyvinyl alcohol, 5 parts of boric acid, and 150 parts of ionized water, the average particle size of the nano silicon dioxide is 90 nanometers, the molecular weight of the polyvinyl alcohol is 5000, and the thickness of the printing layer is 20 μm.

[0036] A m...

Embodiment 3

[0043] A reflective thermal film, comprising a PE / PET composite film 1, a printing layer 2, a glass bead layer 3, an adhesive layer 4, an electroplating layer 5, and a hot-melt adhesive layer 6, which are laminated sequentially from bottom to top. The thickness of PE / PET composite film 1 is 2.0mm; the particle size of the glass beads is 450 mesh; the adhesive layer 4 uses bright silver glue, which can play a reflective role; Layer 6 is a conventional hot melt adhesive in the market. The components of the printing layer 2 are made up of the following raw materials in parts by weight: 15 parts of nano silicon dioxide, 8 parts of superfine calcium carbonate, 7 parts of silane coupling agent, 25 parts of polyvinyl alcohol, 4 parts of boric acid, 120 parts of ionized water, 50 parts of acrylate, 2 parts of leveling agent. The average particle size of the nano-silica is 50 nanometers, the molecular weight of the polyvinyl alcohol is 4000, and the thickness of the printing layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com