Metal organic framework material fertilizer and preparation method thereof

A metal-organic framework and fertilizer technology, applied in the directions of organic fertilizers, organic phosphate fertilizers, fertilizer mixtures, etc., can solve problems such as few reports, and achieve stable nutrient release, good controlled release effect, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

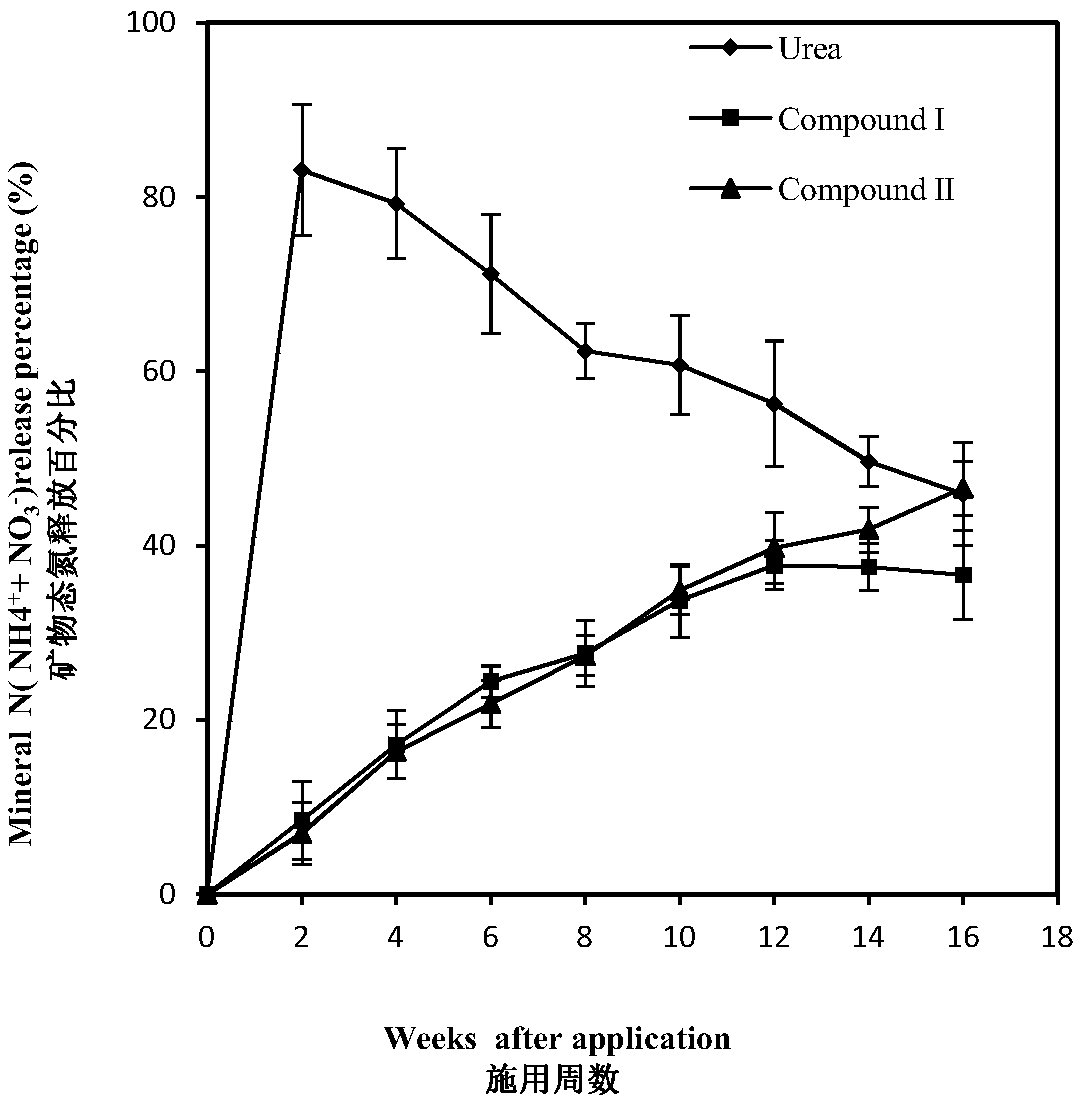

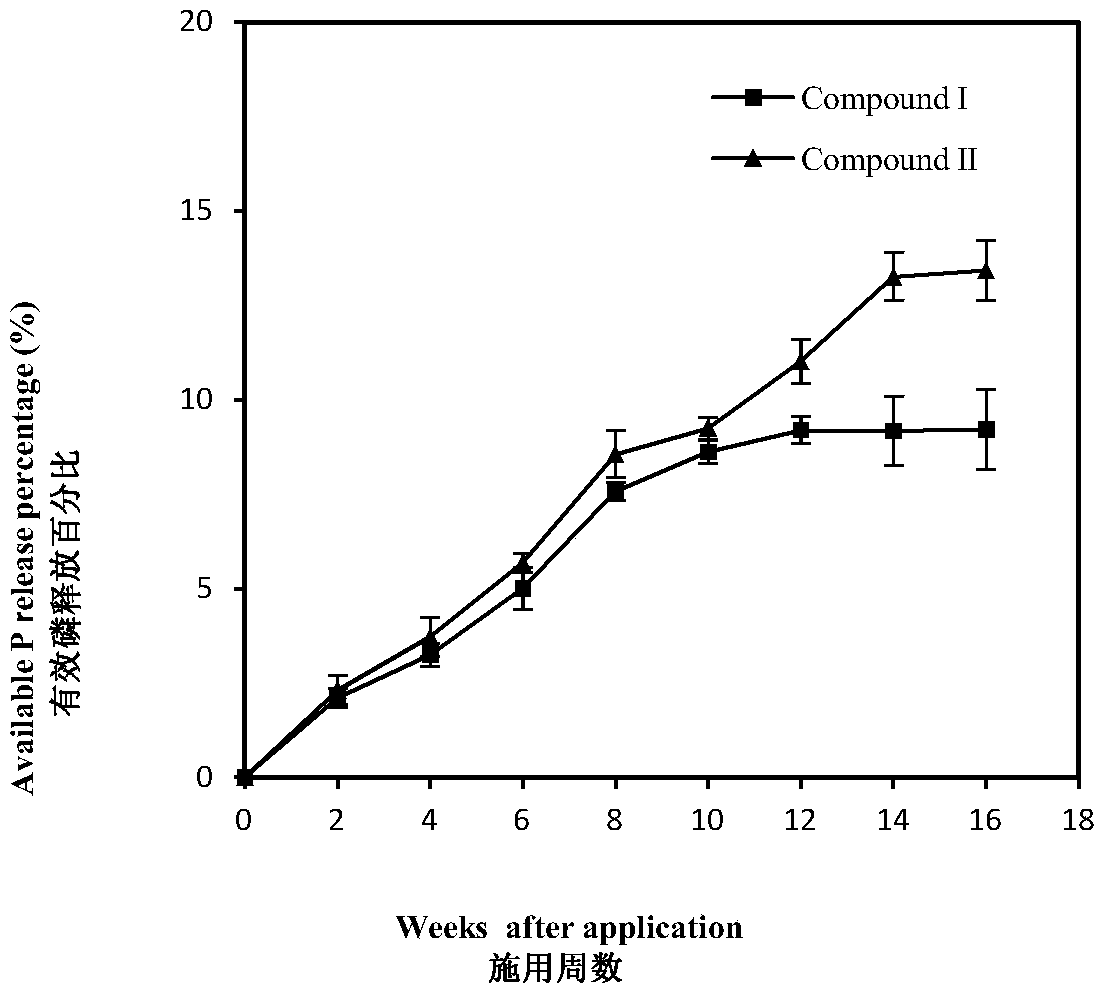

[0076] Embodiment 1, metal-organic framework material fertilizer and preparation method thereof, preparation of compound I: take 1 mole of ferric chloride, 6 moles of phosphoric acid, 1 mole of oxalic acid, urea (CO(NH 2 ) 2 ) 3 moles, deionized water (H 2 O) Put 100 moles in a beaker and stir with a glass rod. After the reaction substrate is completely dissolved and mixed evenly, pour it into the reaction kettle and seal it completely. Set the reaction temperature to 100°C, and the reaction time is 24h. The stirring speed was set at 2°C / min, and the rotation speed of the stirring bar was set at 120 rpm. After the reaction was completed, the reaction kettle was opened when the temperature dropped to room temperature, the solution was filtered with filter paper, and then washed with deionized water for 3 times to obtain the product.

[0077] Nutrient release measurement method: accurately weigh 0.13g of urea, mix it with 300g of test soil, and then add it to a culture plate wi...

Embodiment 2

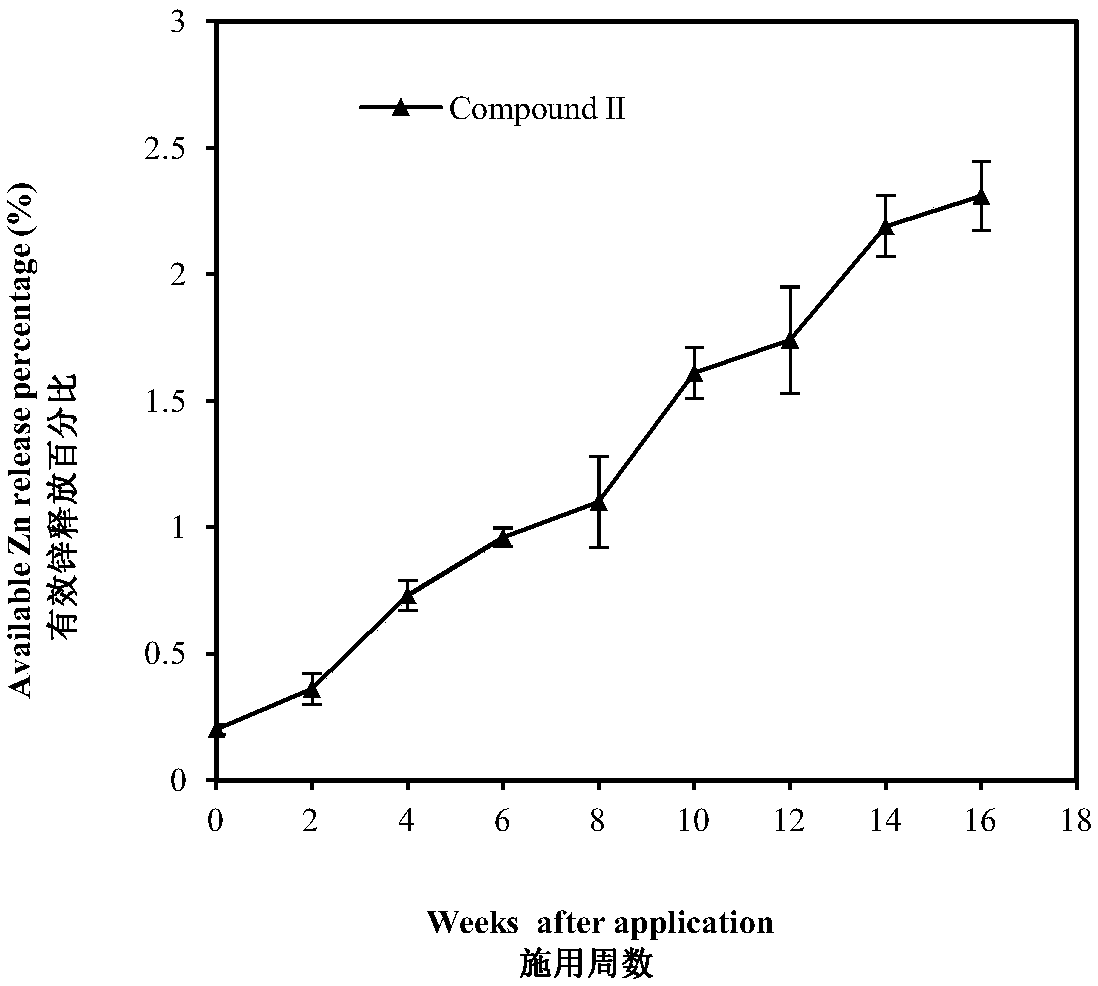

[0078] Embodiment 2, metal-organic framework material fertilizer and preparation method thereof, preparation of compound II: Weigh 1 mole of ferric chloride, 0.25 mole of zinc sulfate, 6 moles of phosphoric acid, 1 mole of oxalic acid, urea (CO(NH 2 ) 2 ) 3 moles, deionized water (H 2 O) Put 100 moles in a beaker and stir with a glass rod. After the reaction substrate is completely dissolved and mixed evenly, pour it into the reaction kettle and seal it completely. Set the reaction temperature to 100°C, and the reaction time is 24h. The stirring speed was set at 2°C / min, and the rotation speed of the stirring bar was set at 120 rpm. After the reaction was completed, the reaction kettle was opened when the temperature dropped to room temperature, the solution was filtered with filter paper, and then washed with deionized water for 3 times to obtain the product.

Embodiment 3

[0079] Embodiment 3 is basically the same as Embodiment 1, but with the following changes: the molar ratio of the metal-organic framework material composition is: ferric chloride (FeCl 3 ·6H 2 O) 0.25, phosphoric acid (H 3 PO 4 ) 5, oxalic acid (H 2 C 2 o 4 2H 2 O) 0.5, urea (CO(NH 2 ) 2 ) 3. Deionized water (H 2 O) 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com