Environment-friendly material and method for preparing same

A technology of environmentally friendly materials and pigments, applied in anti-corrosion coatings, anti-fouling/underwater coatings, biocide-containing paints, etc., can solve the problems of high cost, environmental pollution, and not being widely used, and achieve low production costs and improved Anti-corrosion performance, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

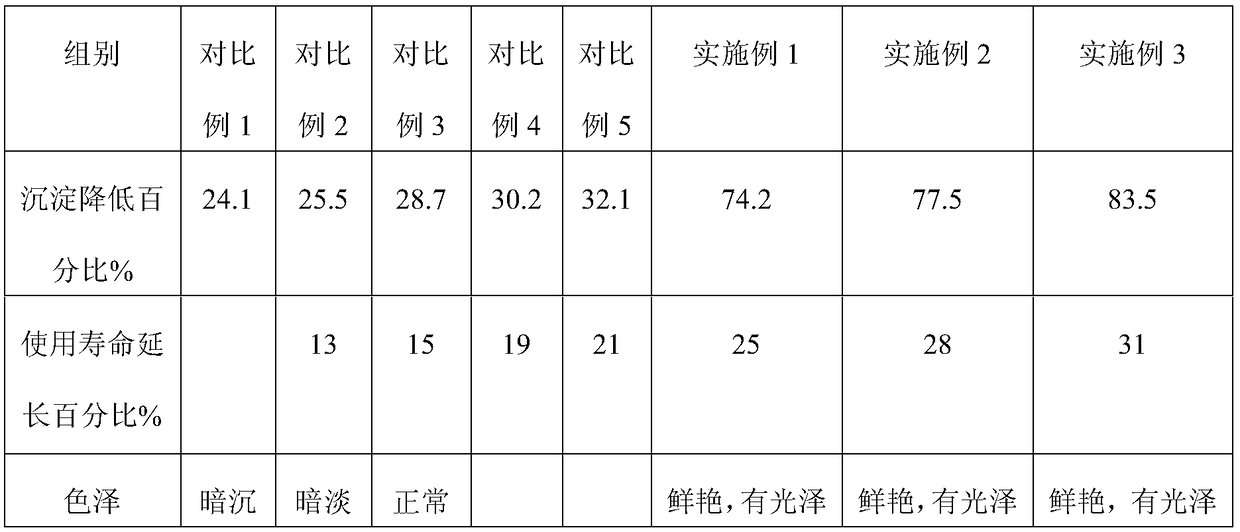

Examples

Embodiment 1

[0027] An environmentally friendly material, mainly made of the following raw materials in parts by weight: 20 parts of polyvinyl acetate, 5 parts of vinyl formate, 15 parts of water-soluble epoxy resin, 10 parts of n-butyl acetate, 5 parts of anti-settling agent, and 10 parts of pigment , 1 part of other additives and 30 parts of deionized water;

[0028] Among them, the anti-sedimentation agent is composed of organic bentonite and castor oil;

[0029] Other additives are mixed with curing agent, thickener, defoamer and film-forming aid;

[0030] The pigment is mainly made of the following raw materials in parts by weight: 10 parts of beet, 10 parts of crab apple bark, 10 parts of amurberry bark, 10 parts of hibiscus flower, 10 parts of St. John's wort, 10 parts of rose flower, 10 parts of sumac fruit, madder 20 parts, 15 parts of safflower, 10 parts of red yeast rice and 10 parts of red pepper; the preparation method is:

[0031] S1: Wash and pulverize bark of amurberry ba...

Embodiment 2

[0039] An environmentally friendly material, mainly made of the following raw materials in parts by weight: 25 parts of polyvinyl acetate, 7 parts of vinyl formate, 17 parts of water-soluble epoxy resin, 13 parts of n-butyl acetate, 6 parts of anti-settling agent, and 15 parts of pigment , 1.5 parts of other additives and 45 parts of deionized water;

[0040] Among them, the anti-settling agent is composed of polyvinyl alcohol wax and polyamide wax;

[0041] Other additives are mixed with curing agent, thickener, defoamer and film-forming aid;

[0042] The pigment is mainly made of the following raw materials in parts by weight: 13 parts of beet, 15 parts of crab apple bark, 15 parts of amurberry bark, 15 parts of hibiscus flower, 13 parts of St. John's wort, 11 parts of rose flower, 15 parts of sumac fruit, madder 25 parts, 17 parts of safflower, 20 parts of red yeast rice and 15 parts of red pepper; its preparation method is:

[0043] S1: Wash and pulverize the bark of Phe...

Embodiment 3

[0051] An environmentally friendly material, mainly made of the following raw materials in parts by weight: 30 parts of polyvinyl acetate, 10 parts of vinyl formate, 20 parts of water-soluble epoxy resin, 15 parts of n-butyl acetate, 7 parts of anti-settling agent, and 20 parts of pigment , 2 parts of other additives and 60 parts of deionized water;

[0052] Among them, the anti-settling agent is composed of organic bentonite, castor oil, polyvinyl alcohol wax and polyamide wax;

[0053] Other additives are mixed with curing agent, thickener, defoamer and film-forming aid;

[0054] The pigment is mainly made of the following raw materials by weight: 15 parts of beet, 20 parts of crab apple bark, 20 parts of amurberry bark, 20 parts of hibiscus flower, 15 parts of St. John's wort, 12 parts of rose flower, 20 parts of sumac fruit, madder 30 parts, 20 parts of safflower, 30 parts of red yeast rice and 20 parts of red pepper; its preparation method is:

[0055] S1: Wash and pulver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com