High-strength wear-resistant waterborne epoxy floor coating and preparation method thereof

An epoxy floor paint, water-based epoxy technology, applied in the field of coatings, can solve the problems of water-based epoxy floor paints with no obvious competitive advantages, low market share, poor wear resistance, etc., and achieve a reasonable formula design. , The effect of short drying time and fast hardening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

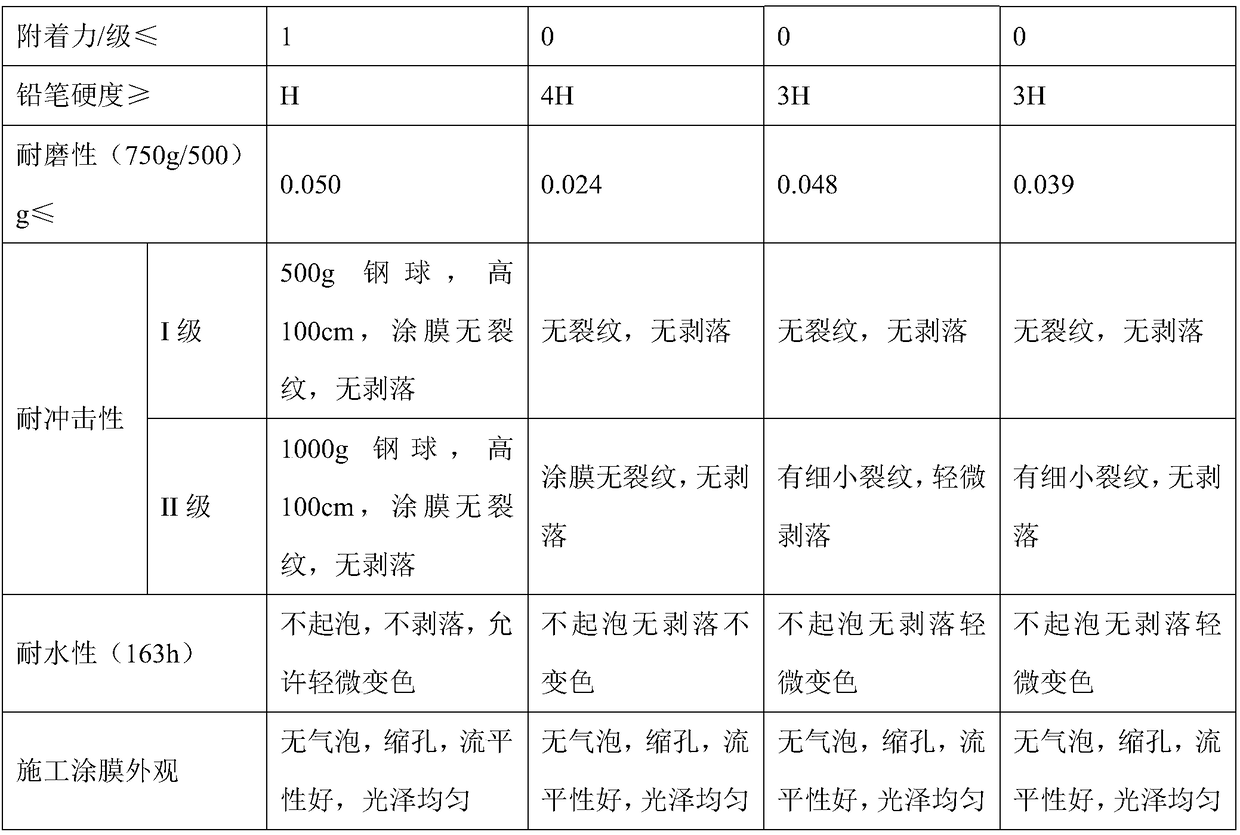

Examples

Embodiment 1

[0030] 1) Waterborne epoxy floor paint formula (by weight):

[0031] Component A: 40 parts of bisphenol A epoxy resin (GEM02 type) and 20 parts of water;

[0032] Component B: 35 parts of water-based epoxy curing agent (GCA02 type), 20 parts of water, 35 parts of filler (talc powder), 4 parts of wetting agent (BYK-346), 0.4 parts of dispersant (SN-5029), disinfectant 0.3 parts of foaming agent (SN-DEFOAMER 319), 10 parts of calcium sulfate whiskers, 3.5 parts of diatomaceous earth and 1.0 parts of nanofibrillar cellulose.

[0033] 2) preparation method, comprises the following steps:

[0034] The production method of component A is: add the epoxy resin and water in the formula amount into the batching tank, adjust the speed of the mixer to 300-500rpm, stir and mix for 5-10min, and pack;

[0035] The manufacturing method of component B is: add filler, dispersant, calcium sulfate whisker, diatomaceous earth and nanofibril cellulose in the batching tank, add water under slow st...

Embodiment 2

[0037] 1) Waterborne epoxy floor paint formula (by weight):

[0038] Component A: 30 parts of bisphenol A epoxy resin (GEM02 type) and 10 parts of water;

[0039]Component B: 20 parts of water-based epoxy curing agent (Sunmide WH-900), 20 parts of water, 10 parts of filler (quartz sand), 2 parts of wetting agent (BYK-333), 0.2 parts of dispersant (SN-5029) , 0.2 parts of defoamer (SN-DEFOAMER 318), 5 parts of calcium sulfate whiskers, 1 part of diatomaceous earth and 0.5 parts of nanocrystalline cellulose.

[0040] 2) The preparation method is the same as in Example 1.

Embodiment 3

[0042] 1) Waterborne epoxy floor paint formula (by weight):

[0043] Component A: 50 parts of bisphenol A epoxy resin (GEM02 type) and 30 parts of water;

[0044] Component B: 50 parts of water-based epoxy curing agent (Sunmide WH-900), 30 parts of water, 60 parts of filler (talc powder), 6 parts of wetting agent (BYK-333), 0.4 parts of dispersant (SN-5029) , 0.4 parts of defoamer (SN-DEFOAMER 318), 15 parts of calcium sulfate whiskers, 5 parts of diatomaceous earth and 2 parts of nanocellulose.

[0045] 2) The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com