A fully automatic coupling control system of a transmission line inspection robot

An inspection robot, coupled control technology, applied in the control system, motor speed or torque control, control/adjustment system, etc., can solve problems such as difficulty in achieving control results, and the adjustment of control parameters cannot achieve predetermined effects. , to achieve the effect of strong universality and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention is further described below in conjunction with accompanying drawing:

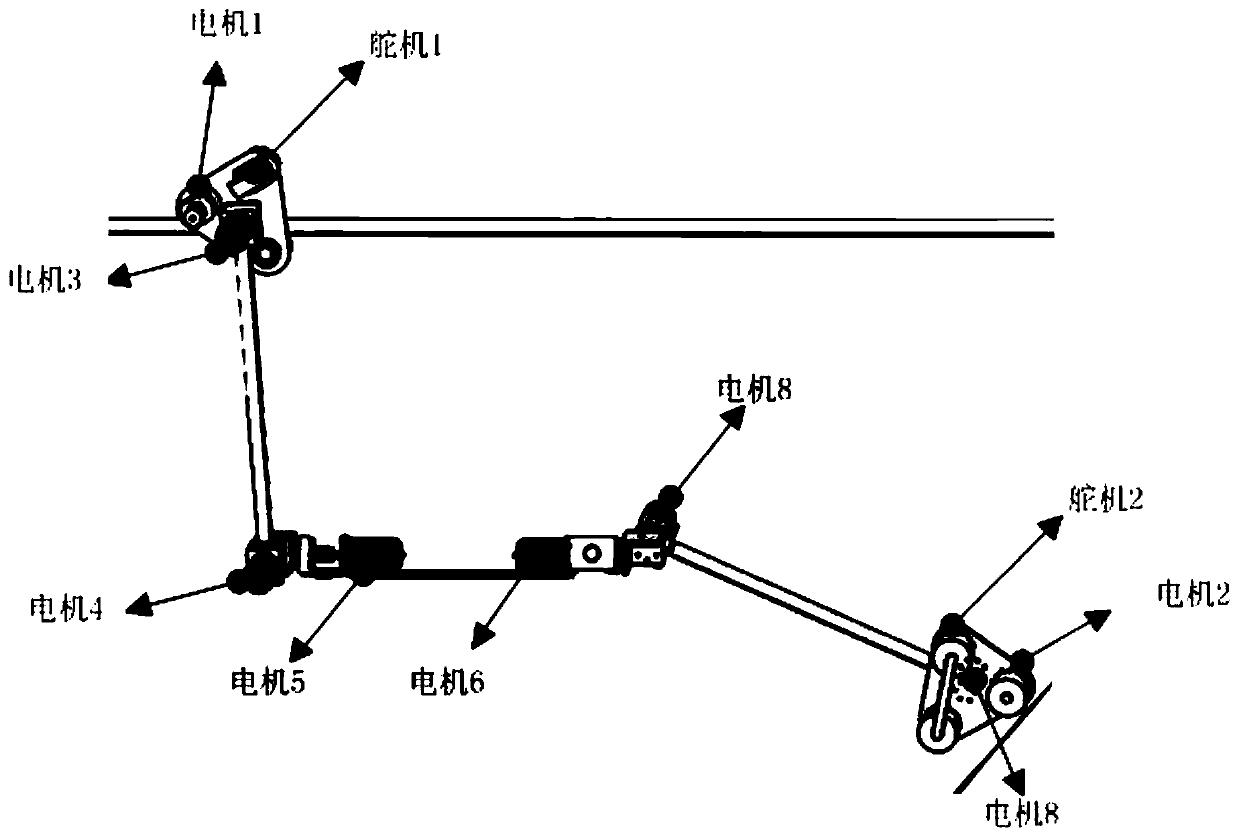

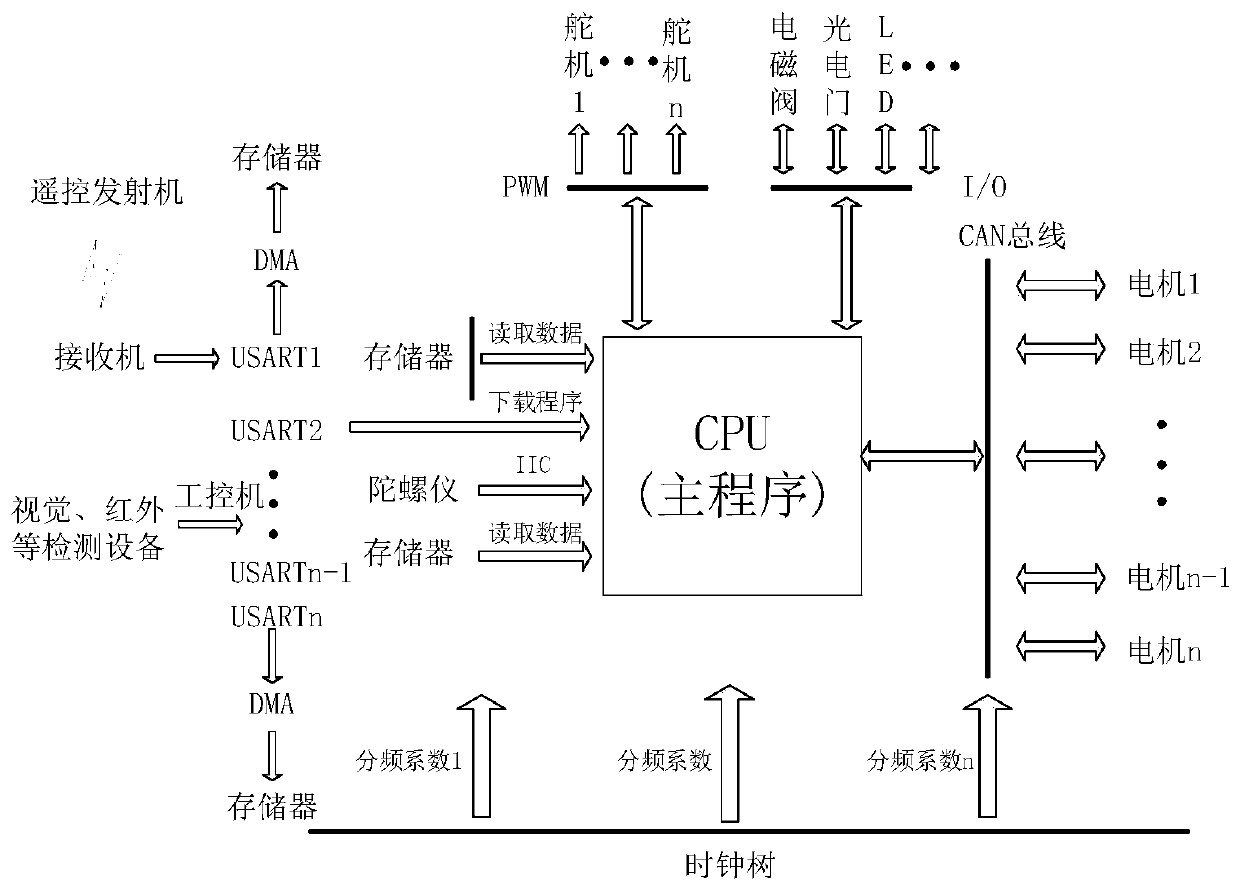

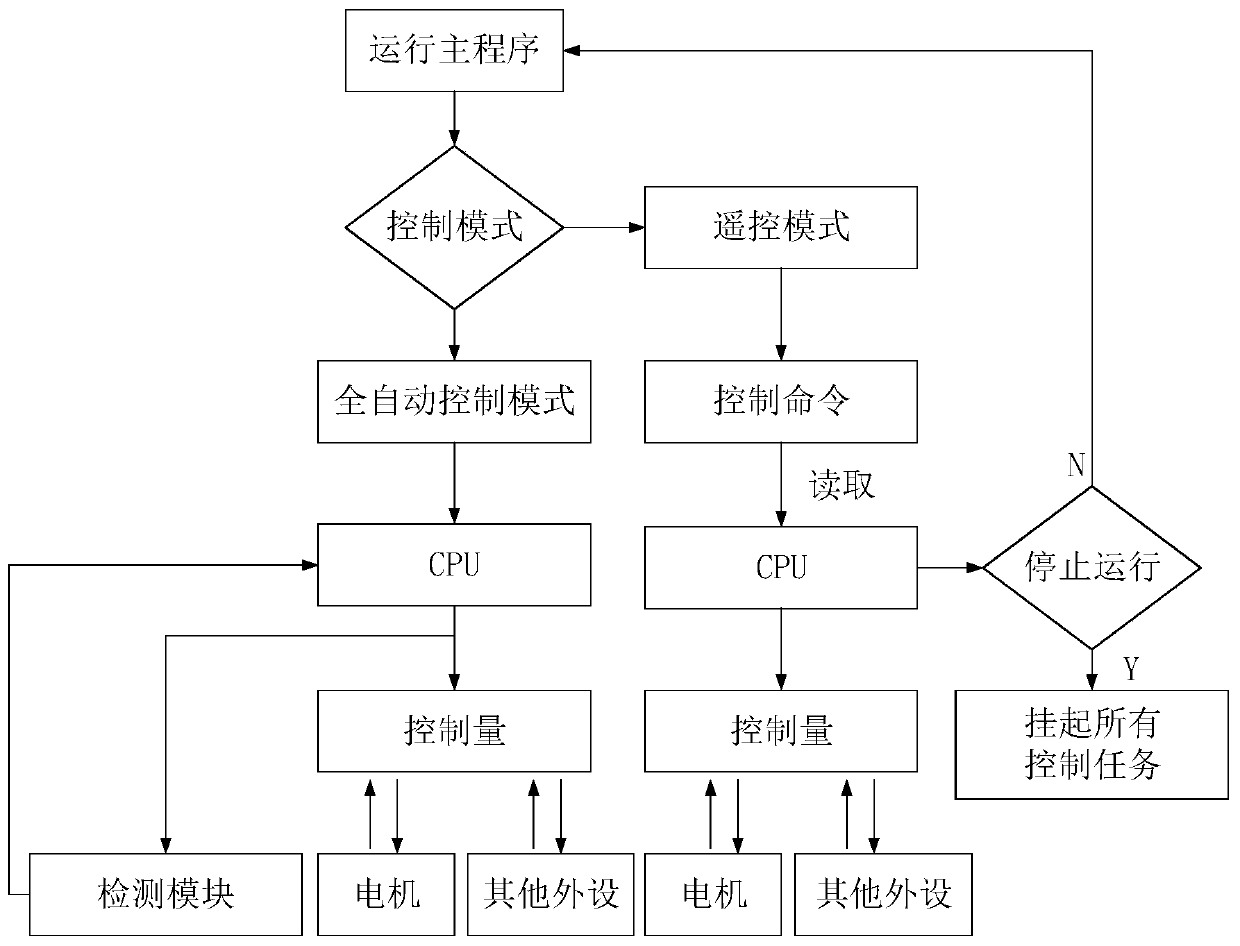

[0063] The overall structure of the control system is as image 3 As shown, it mainly includes: center of gravity adjustment control module such as Figure 4 As shown, the trajectory tracking control module is as follows Figure 5 As shown, the fully automatic control module is the entire control system such as figure 2 As shown, there are 3 innovative modules such as , etc. In addition, there are 5 basic functional modules such as remote control function module, fault detection module, motor control module, peripheral control module, and taxiing control module. The 8 modules are mainly composed of the central processing unit, the clock tree, and the serial port module USART; the remaining serial ports are mainly used to receive data transmitted by other peripherals and store them in the memory through DMA, and the data sent by the transmitter and receiver of the remote contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com