Phosphorus-doped cerium titanium catalyst as well as preparation method and application thereof to selective catalytic reduction denitrification

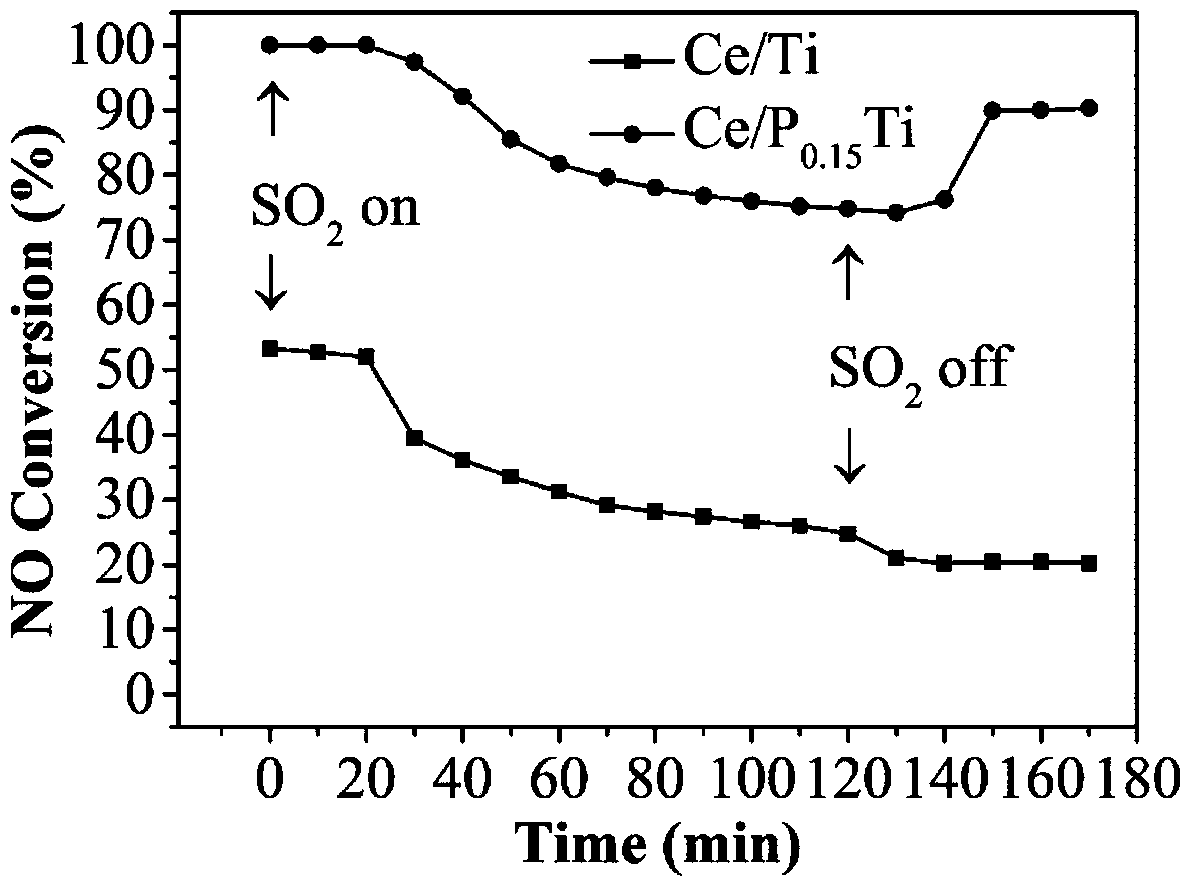

A phosphorus doping and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reduced activity and selectivity, and achieve the improvement of N2 selectivity and reduction of non-selectivity. The effect of oxidation probability, good resistance to SO2 poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

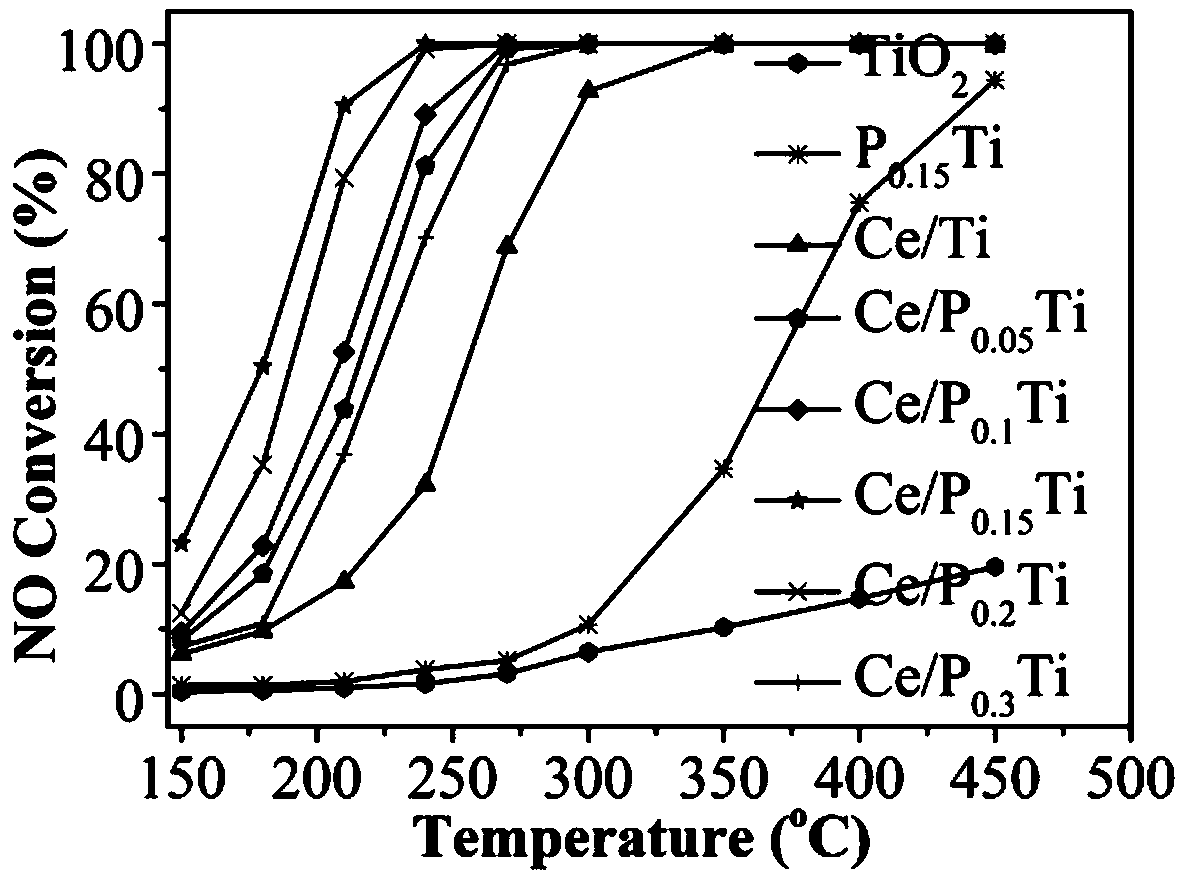

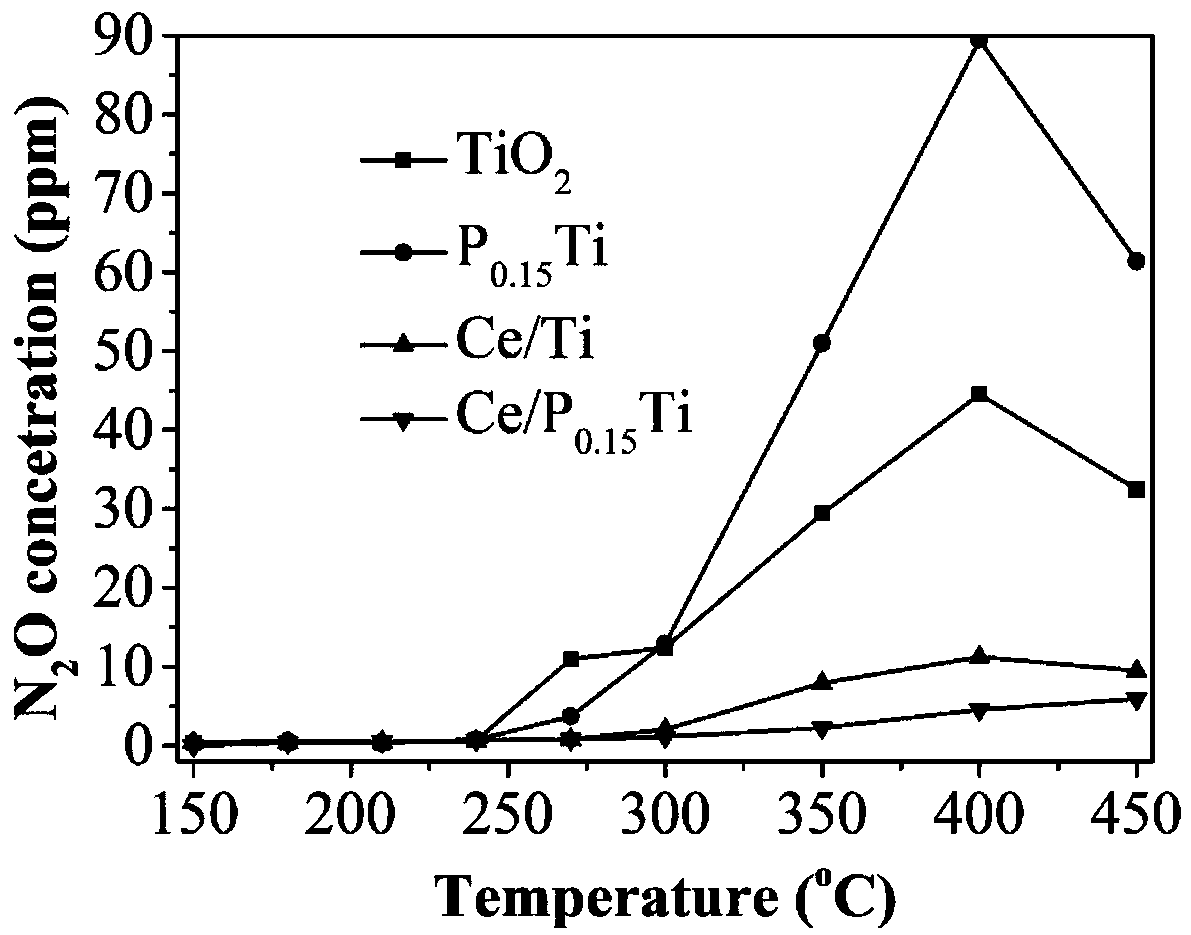

[0026] P x TiO 2 Prepared by co-precipitation method. Phosphoric acid (H 3 PO 4 , 85wt.%) and titanium sulfate (Ti(SO 4 ) 2 ) are the precursors of P and Ti, respectively. Ammonia (NH 3 ·H 2 O, 25wt.%) as an alkali source. Different molar ratios (P and TiO 2 The molar ratios are x=0.05,0.1,0.15,0.2,0.3) of H 3 PO 4 and Ti(SO 4 ) 2 Mix evenly in deionized water under stirring, then slowly drop the ammonia solution into the aqueous solution until the pH is adjusted to 10, after stirring for 2 hours, keep the mixture at room temperature for 24 hours, dry at 80°C, then dry at 450°C Calcined for 4 hours to prepare P x TiO 2 carrier. Pure TiO 2 Prepared by the method described above without the addition of phosphoric acid.

[0027] 20wt%CeO 2 / TiO 2 and 20wt% CeO 2 / P x Ti(m CeO2 / (m CeO2 +m TiO2 )=20%) The catalyst was prepared by impregnation method. Ce(NO 3 ) 3 ·6H 2 O and the carrier were uniformly mixed in deionized water, heated and stirred. After...

Embodiment 2

[0029] 10wt% Ce / Ti, 10wt% Ce / P x Ti, 30wt% Ce / Ti and 30wt% Ce / P x Ti catalysts were prepared by impregnation. Ce(NO 3 ) 3 ·6H 2O and the carrier were uniformly mixed in deionized water, heated and stirred. After stirring for 2 h, the mixture was dried at 80 °C and then calcined at 700 °C for 2 h to obtain 10-Ce / Ti, 10-Ce / P x Ti, 30-Ce / Ti and 30-Ce / P x Ti catalyst.

Embodiment 3

[0031] P x TiO 2 Prepared by co-precipitation method. h 3 PO 4 and Ti(SO 4 ) 2 Mix evenly in deionized water under stirring, then slowly drop the ammonia solution into the aqueous solution until the pH is adjusted to 10, after stirring for 2 hours, keep the mixture at room temperature for 24 hours, then dry the mixture at 80°C, then Calcined at 700°C for 2 hours, P 0.15 TiO 2 carrier. Pure TiO 2 Prepared by the method described above without the addition of phosphoric acid.

[0032] The cerium-titanium catalyst was prepared by the impregnation method. Ce(NO 3 ) 3 ·6H 2 O and the carrier were uniformly mixed in deionized water, heated and stirred. After stirring for 2 h, the mixture was dried at 80 °C and then calcined at 700 °C for 2 h to give Ce / Ti-700 and Ce / P 0.15 Ti-700 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com