A high-temperature dust removal filter sleeve and its preparation method

A technology of high-temperature dust removal and dust removal pipes, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of reducing the filtration speed of filter materials, increasing the air resistance of filter materials, and affecting the purification of high-temperature flue gas and dust And efficiency and other issues, to achieve the effect of good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention also provides a method for preparing the high-temperature dust-removing filter casing described in the above-mentioned technical solution, comprising the following steps:

[0075] a) mixing 100 parts by weight of ceramic fibers with water, beating, diluting and removing slag in sequence, and then uniformly mixing with 3 to 10 parts by weight of an organic binder and 5 to 20 parts by weight of an inorganic binder to obtain a slurry; Then the obtained slurry is formed, dehydrated and dried in sequence to obtain a blank; after processing, the first dust removal pipe is obtained;

[0076] b) Mix 100 parts by weight of ceramic fibers, 10 to 35 parts by weight of a pore control agent with water, perform beating, dilution and deslagging in sequence, and then mix 3 to 10 parts by weight of an organic binder, 5 to 20 parts by weight of The inorganic binder is evenly mixed to obtain a slurry; then the obtained slurry is sequentially molded, dehydrated and dr...

Embodiment 1

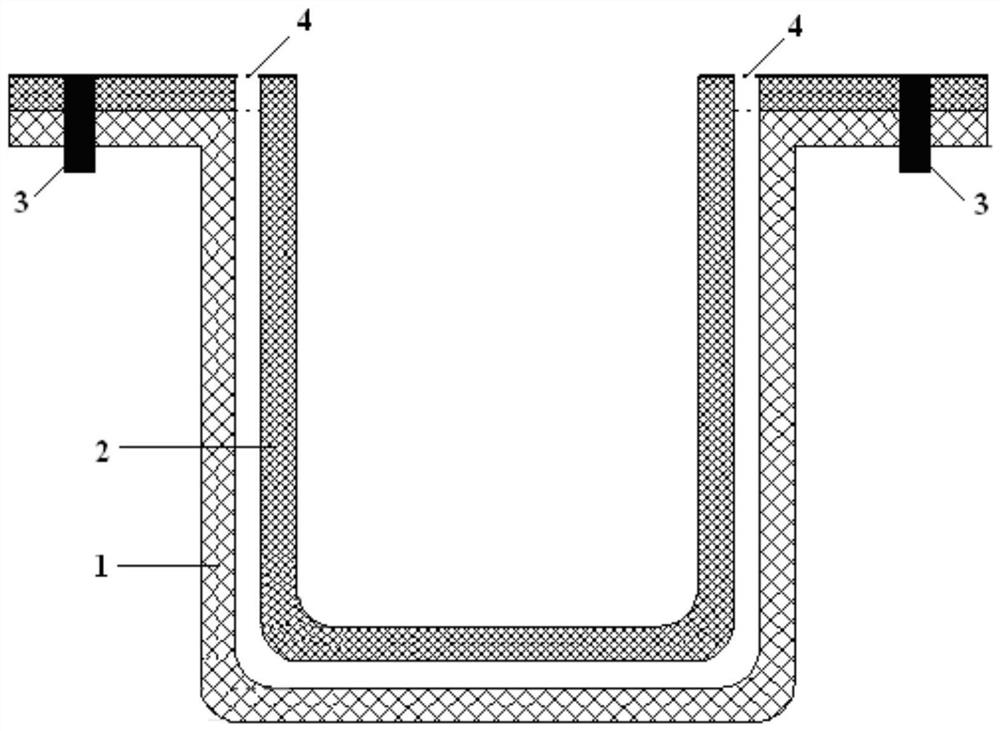

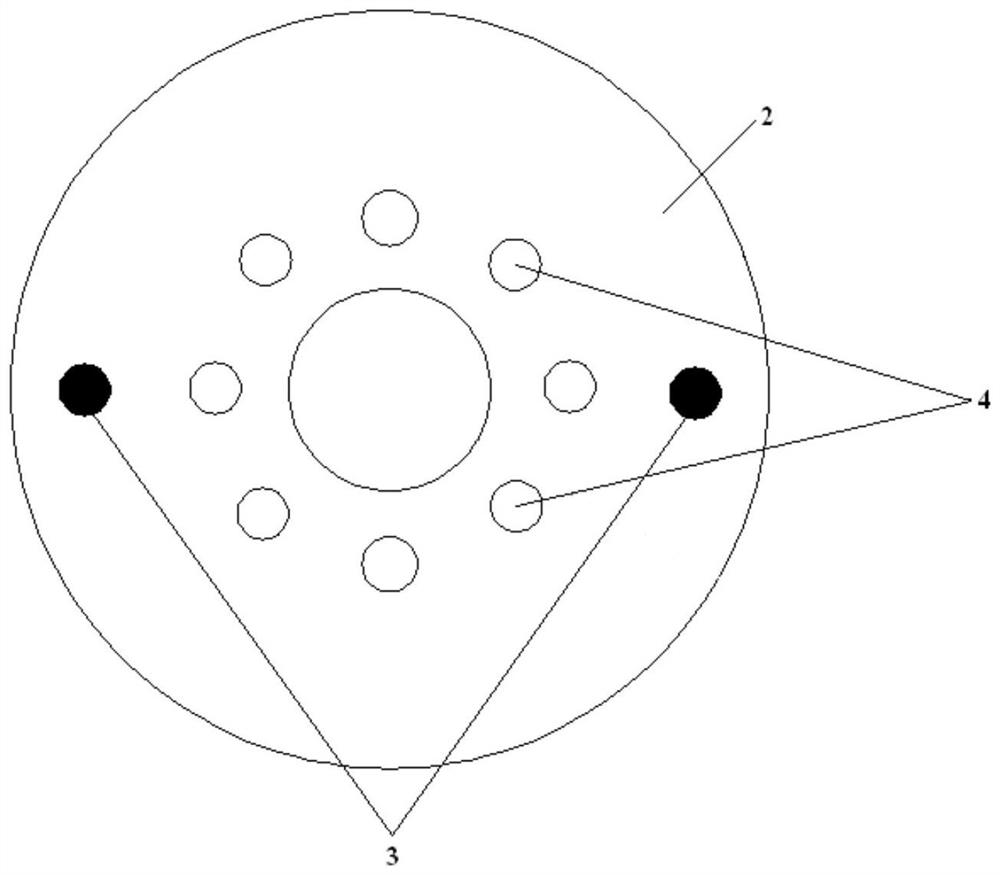

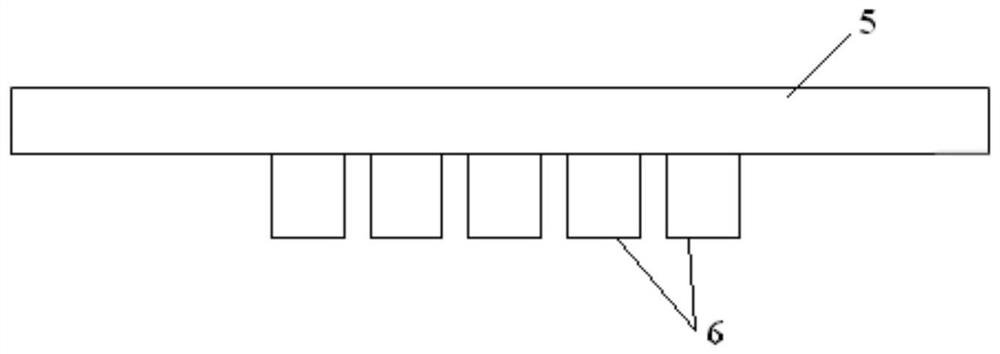

[0097] The schematic diagram of the structure of the high-temperature dust removal filter sleeve provided by Embodiment 1 of the present invention is as follows Figure 1~3 shown; among them, figure 1 The sectional view of the high-temperature dust removal filter casing provided for embodiment 1, figure 2 The top view of the high-temperature dust removal filter casing provided for embodiment 1, image 3 A cross-sectional view of the plug used in the high-temperature dust removal filter sleeve provided in Example 1. Figure 1~3 Among them, 1 is the first dust removal pipe, 2 is the second dust removal pipe, 3 is the bolt, 4 is the exhaust hole, 5 is the plug cover, and 6 is the exhaust hole plug. Wherein, the wall thickness of the first dust removal casing is 20mm, the inner diameter is 160mm, the outer diameter is 200mm, and the outer diameter of the ring plane is 240mm; the wall thickness of the second dust removal casing is 20mm, the inner diameter is 100mm, and the outer...

Embodiment 2

[0102] The schematic diagram of the structure of the high-temperature dust removal filter sleeve provided by Embodiment 2 of the present invention is as follows Figure 1~3 shown; among them, figure 1 The sectional view of the high-temperature dust removal filter casing provided for embodiment 2, figure 2 The top view of the high-temperature dust removal filter casing provided for embodiment 2, image 3 A cross-sectional view of the plug used in the high-temperature dust removal filter sleeve provided in Example 2. Figure 1~3 Among them, 1 is the first dust removal pipe, 2 is the second dust removal pipe, 3 is the bolt, 4 is the exhaust hole, 5 is the plug cover, and 6 is the exhaust hole plug. Wherein, the wall thickness of the first dust removal casing is 20mm, the inner diameter is 160mm, the outer diameter is 200mm, and the outer diameter of the ring plane is 240mm; the wall thickness of the second dust removal casing is 20mm, the inner diameter is 100mm, and the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com