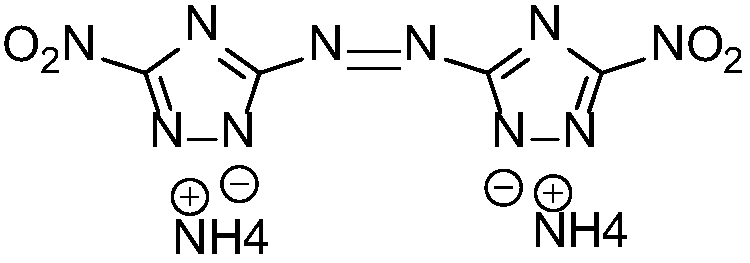

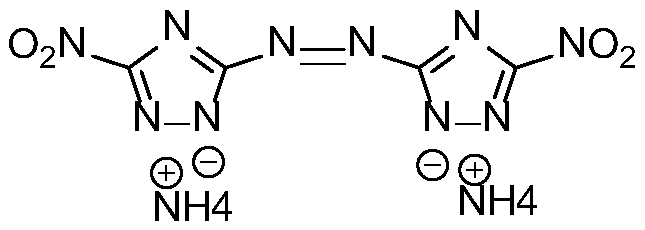

Preparation method and property of 3,3'-dinitro-5,5'-azo-1H-1,2,4-triazole diammonium salt structure

A technology of dinitro and diammonium salts, which is applied in the direction of offensive equipment, nitrated explosive components, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., to achieve easy large-scale production, simple synthesis method, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

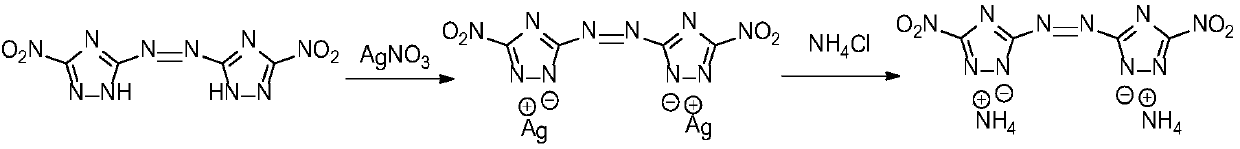

[0021] Add 2.54g (10mmol) 3,3'-dinitro-5,5'-azo-1H-1,2,4-triazole and 50ml water to a 100ml single-necked bottle equipped with magnetic stirring, and heat to make it Dissolved, then quickly added (3.40g, 10mmol) silver nitrate, stirred in the dark for 1h, filtered to obtain a yellow solid 3,3'-dinitro-5,5'-azo-1H-1,2,4-tri azole silver salt 4.30g, yield 92%; elemental analysis: C 4 Ag 2 N 10 o 4 (467.84) (%) Calculated: C 10.27, H 0.00; N 29.94; Found: C 10.09, H 0.08, N 29.71.

[0022] 467 mg (1 mmol) of 3,3'-dinitro-5,5'-azo-1H-1,2,4-triazole silver salt was added to an aqueous solution (50 mL) of 107 mg (2 mmol) of ammonium chloride. Stir at 80°C for 4h, and filter off AgCl precipitate while hot. The filtrate was evaporated to dryness, recrystallized with water, and dried to obtain 219 mg of 3,3'-dinitro-5,5'-azo-1H-1,2,4-triazole bis-ammonium salt with a yield of 76%. Decomposition temperature: 248°C (DSC, heating rate 5°C / min). IR(neat):3255,2962,2835,1684,1524,148...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com