Pushing plate furnace for producing cathode material of lithium ion battery

A lithium-ion battery and positive electrode material technology, applied in the field of mechanical equipment, can solve the problems of slow cooling efficiency and low production efficiency, and achieve the effect of improving production efficiency and cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

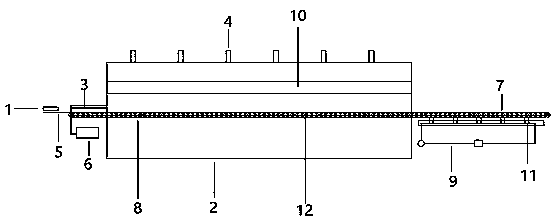

[0016] A pusher furnace for producing lithium-ion battery cathode materials, comprising a special sagger 1 and a pusher furnace 2, characterized in that the special sagger 1 and the pusher furnace 2 are movably connected, and the pusher furnace 2 includes Material channel 5, push plate furnace shell, insulation layer, heating system 10, furnace atmosphere control system, temperature control system, transmission system, discharge channel 7 and cooling system 9, said furnace atmosphere control system includes an air inlet 3 and several gas outlets 4, the gas inlet 3 is arranged in the feed channel 5, and the gas outlet 4 is arranged above the pushing plate furnace 2.

[0017] Further, the transmission system includes a controller, a motor 6, several driving rollers 8, a position sensor 12 and a driving chain; there are 44 driving rollers.

[0018] Further, the pusher furnace shell is a cuboid with a furnace cavity, and the pusher furnace shell is welded by steel materials; the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com