Reactor and method for preparing methanol by directly oxidizing methane through gas-solid phase continuous photocatalysis

A reactor, photocatalytic technology, applied in the direction of oxidation reaction preparation, chemical instruments and methods, organic chemistry, etc., can solve the research and development of lagging photocatalysts, difficulties in catalyst recovery and post-processing, uneven light distribution in reactors, etc. problems, achieve the effects of less attenuation, easy disassembly and cleaning, and improved stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

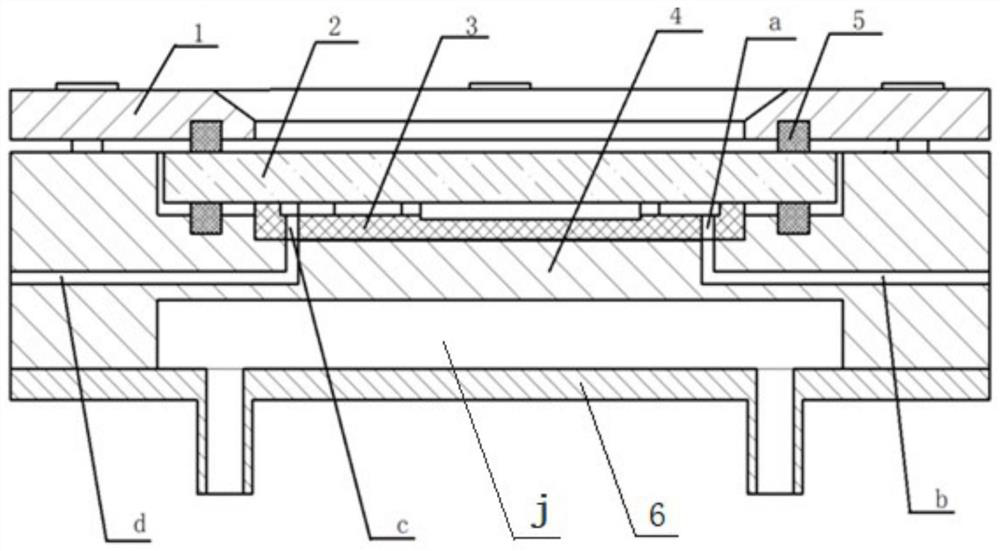

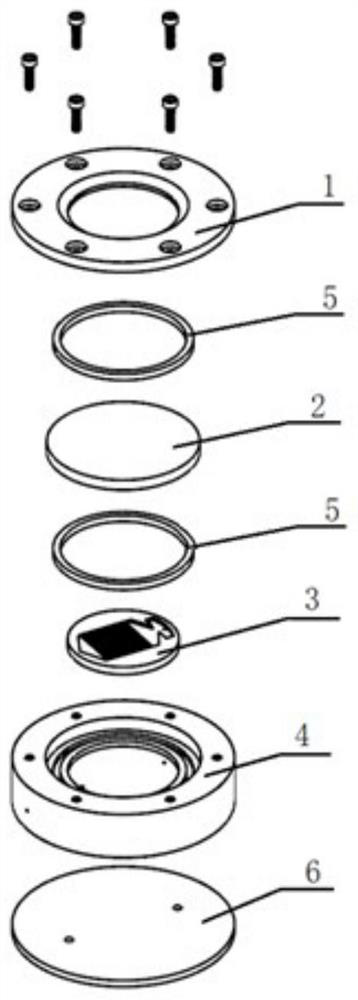

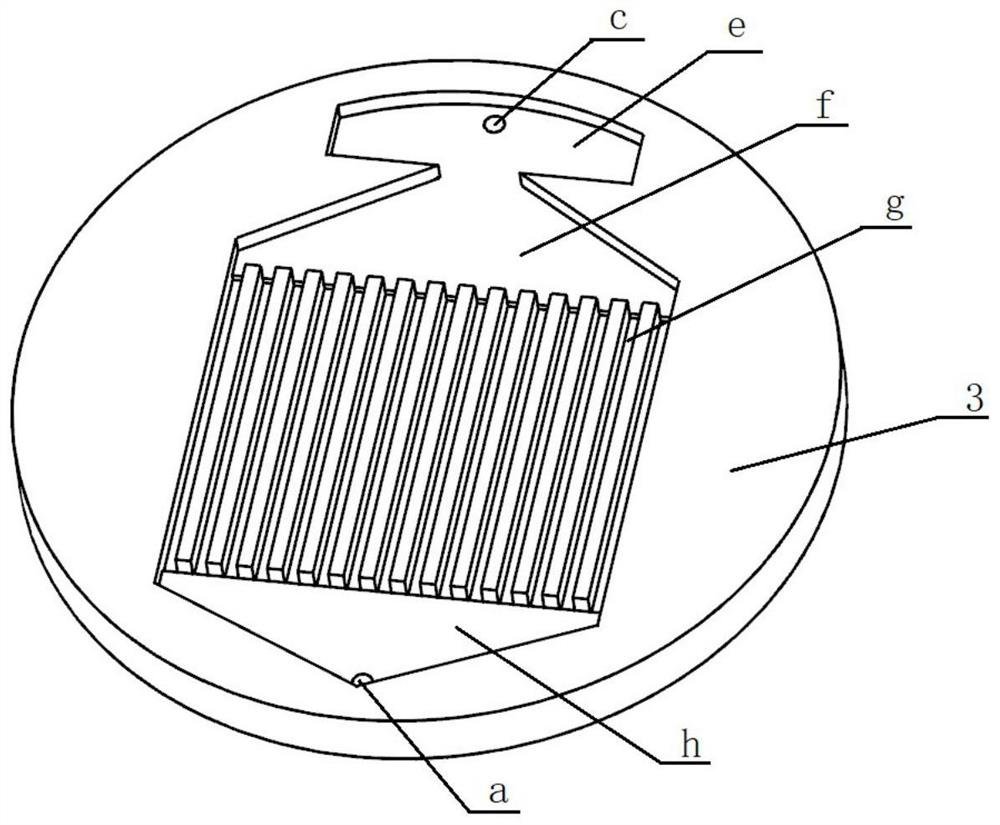

[0042] In this embodiment, the upper surface of the reaction plate 3 is formed with a raw material gas mixing tank e, a gas distribution tank f, a reaction channel g area, and a gas collection tank h which are connected in sequence from one end to the other end. The gas mixing tank e is a rectangular tank with a long side of an arc, the bottom of the raw gas mixing tank e is machined with a first ventilation hole c that communicates with the air inlet channel d, the gas distribution tank f is an isosceles trapezoidal tank, and the gas collection tank h is an isosceles triangular groove, the bottom of the gas collection groove h is machined with a second vent hole a that communicates with the gas outlet channel b, the raw gas mixing groove e, the gas distribution groove f and the gas collection groove h have the same depth, and the reaction channel g area It consists of one reaction channel g. The bottom of the reaction channel g is lower than the bottom of the raw gas mixing ta...

Embodiment 3

[0046] In this embodiment, the upper surface of the reaction plate 3 is formed with a raw material gas mixing tank e, a gas distribution tank f, a reaction channel g area, and a gas collection tank h which are connected in sequence from one end to the other end. The gas mixing tank e is a rectangular tank with a long side of an arc, the bottom of the raw gas mixing tank e is machined with a first ventilation hole c that communicates with the air inlet channel d, the gas distribution tank f is an isosceles trapezoidal tank, and the gas collection tank h is an isosceles triangular groove, the bottom of the gas collection groove h is machined with a second vent hole a that communicates with the gas outlet channel b, the raw gas mixing groove e, the gas distribution groove f and the gas collection groove h have the same depth, and the reaction channel g area It is composed of 30 reaction channels g. The bottom of the reaction channel g is lower than the bottom of the raw gas mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com