Method for manufacturing low-temperature polysilicon thin film transistor

A technology of thin-film transistors and low-temperature polysilicon, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increased heat generation of TFT devices and unfavorable product reliability, etc., to achieve heat dissipation, small channel size, and large line spacing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

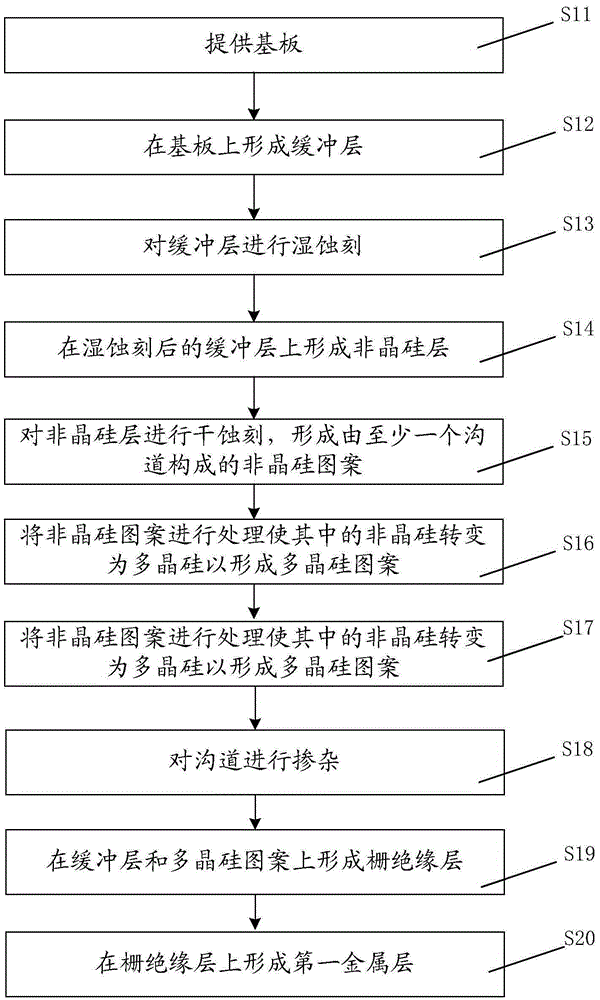

[0025] see figure 1 , figure 1 It is a flow chart of a preferred embodiment of the manufacturing method of the low-temperature polysilicon thin film transistor of the present invention. In this embodiment, the manufacturing method of the low-temperature polysilicon thin film transistor includes the following steps:

[0026] Step S11: providing a substrate.

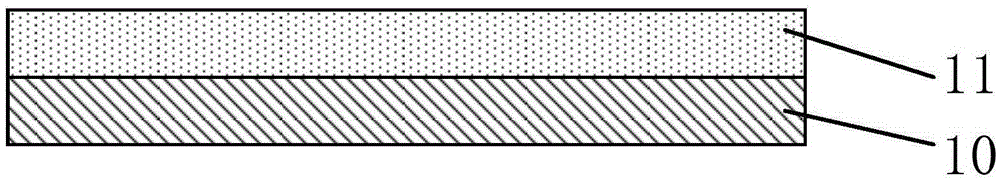

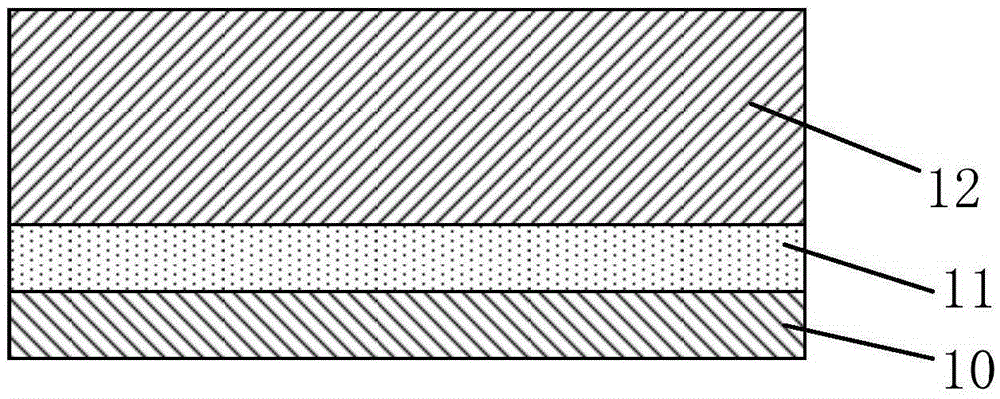

[0027] In step S11, please combine figure 1 refer to figure 2 , figure 2 It is a schematic diagram of the substrate and the first buffer layer in steps S11 and S12 of the manufacturing method of the low-temperature polysilicon thin film transistor of the present invention. Providing the substrate 10 may specifically provide a glass substrate, or providing the substrate 10 may specifically provide a ceramic substrate, or providing the substrate 10 may specifically provide a quartz substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com