Continuous high temperature gas solid reactor

A reactor, high-temperature gas technology, applied in chemical/physical/physicochemical stationary reactors, chemical methods for reacting liquids with non-granular solids, gas/steam mixed with solids, etc., can solve poor fluidization performance , small fluidization velocity, limited adjustment range of residence time, etc., to achieve the effect of reducing reaction dead zone and reducing bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This example illustrates that the reaction time of solid reactants can be precisely controlled by using the gas-solid reactor provided by the present invention for gas-solid reaction.

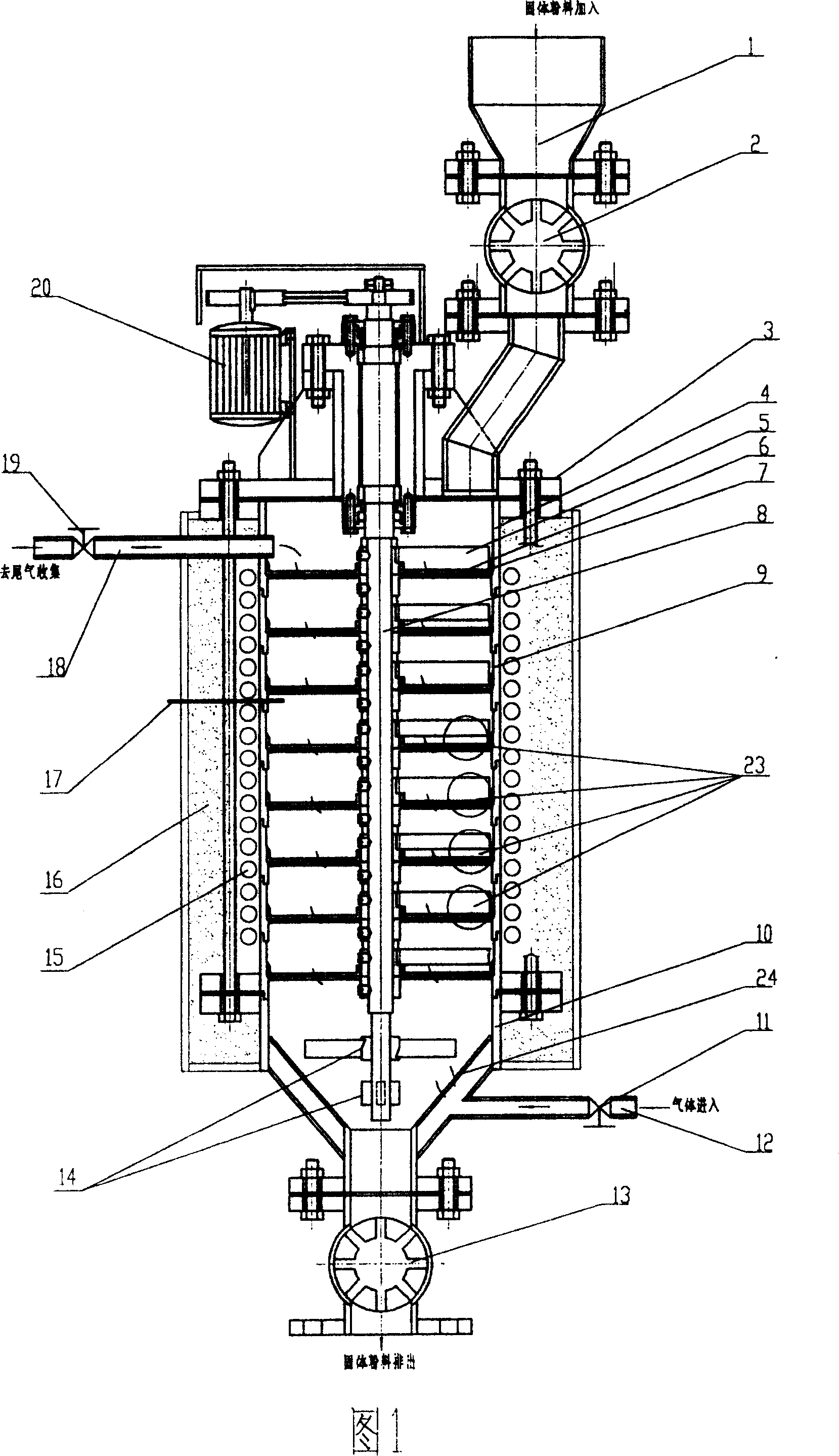

[0041] Manufacture a gas-solid reactor according to the description of the present invention, its structure is as shown in Figure 1. The inner diameter of the reactor is 500mm, and the height of the reactor is 2500mm. There are 8 layers of internal components in the reactor. The total height of the internal components in the reactor is 1600mm. The reactor is heated by electricity, and the reaction temperature in the reactor About 250°C, the motor speed can be adjusted from 0.1 to 100rpm, the feeding and discharging are controlled by the rotary seal, the gas enters from the lower inlet pipe, and the gas volume is controlled by the bottom regulating valve, which can be controlled according to the degree of reaction of the material. The residence time of the solid reaction material is withi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com