Preparation method of shell-core structure nano fiber for lithium battery cathode

A nanofiber and core structure technology, applied in the field of chemical materials, can solve problems such as complex production process, temperature, and oxygen concentration requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

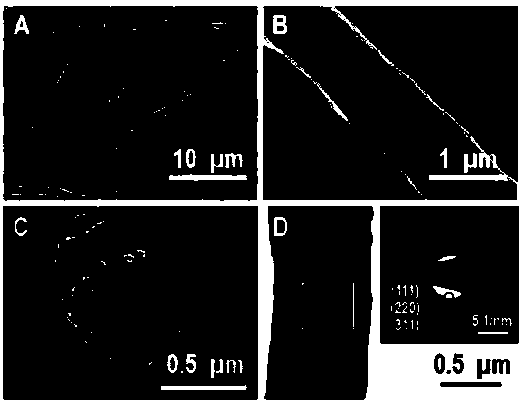

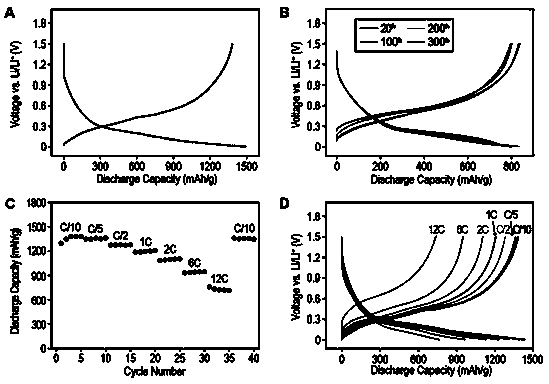

Image

Examples

Embodiment 1

[0022] A method for preparing a shell-core structure nanofiber for a lithium battery negative electrode, comprising the following steps:

[0023] (1) Dissolving silicon nanoparticles and PMMA in a mixed solution of DMF and acetone to form a precursor solution of the core structure of the composite fiber finally obtained. The mass concentration of silicon nanoparticles is 4%, and the mass concentration of PMMA is 9%. The precursor solution of the core structure was stirred and dispersed in an environment of 50° C. for 6 hours; the volume ratio of DMF and acetone in the mixed solution of DMF and acetone was 1:1.

[0024] (2) Dissolve PAN in DMF to form a shell-structured precursor solution in the final composite fiber with a mass concentration of 9%. The shell-structured precursor solution was stirred and dispersed at 70°C for 7h.

[0025] (3) The coaxial electrospinning parameters are as follows: the thickness ratio of the inner and outer layers of the coaxial needle is 1:1, th...

Embodiment 2

[0029] A method for preparing a shell-core structure nanofiber for a lithium battery negative electrode, comprising the following steps:

[0030] (1) Dissolving silicon nanoparticles and PMMA in a mixed solution of DMF and acetone to form a precursor solution for the core structure of the final composite fiber. The mass concentration of silicon nanoparticles is 5%, and the mass concentration of PMMA is 11%. The precursor solution of the core structure was stirred and dispersed at 55° C. for 7 hours; the volume ratio of DMF and acetone in the mixed solution of DMF and acetone was 1:1.

[0031] (2) Dissolve PAN in DMF to form a shell-structured precursor solution in the final composite fiber with a mass concentration of 12%; the shell-structured precursor solution was stirred and dispersed at 50°C for 6h.

[0032] (3) The coaxial electrospinning parameters are as follows: the thickness ratio of the inner and outer layers of the coaxial needle is 1:1, the liquid output ratio of t...

Embodiment 3

[0035] A method for preparing a shell-core structure nanofiber for a lithium battery negative electrode, comprising the following steps:

[0036] (1) Dissolving silicon nanoparticles and PMMA in a mixed solution of DMF and acetone to form a precursor solution for the core structure of the final composite fiber. The mass concentration of silicon nanoparticles is 6%, and the mass concentration of PMMA is 12%. The precursor solution of the core structure was stirred and dispersed at 60° C. for 8 hours; the volume ratio of DMF and acetone in the mixed solution of DMF and acetone was 1:1.

[0037] (2) Dissolve PAN in DMF to form a shell-structured precursor solution in the final composite fiber with a mass concentration of 11%. The shell-structured precursor solution was stirred and dispersed at 65°C for 7.5h.

[0038](3) The coaxial electrospinning parameters are as follows: the thickness ratio of the inner and outer layers of the coaxial needle is 1:1, the liquid output ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com