Colla carapacis preparation process

A preparation process and technology of tortoise shell glue, applied in medical preparations containing active ingredients, blood diseases, extracellular fluid diseases, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

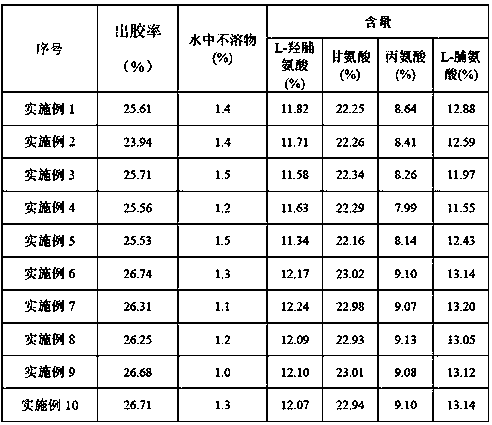

Examples

Embodiment 1

[0031] Raw material ratio:

[0032] Tortoise shell 250kg, soybean oil 2.6kg, rock sugar 2.4kg, rice wine 1.0kg

[0033] Preparation Process:

[0034] S1 Tortoise shell pre-treatment: Select a dry tortoise shell, use 40% NaOH solution to smear the carrion of the tortoise shell, the smear is based on the full coverage, after ultrasonic treatment with a frequency of 150KHz for 5 minutes, microwave treatment with a power of 0.8KW for 1.5 minutes, take it out, Repeat the above operation for 2 more times, after the last microwave treatment, put it into clean water, and after 100KHz ultrasonic treatment for 5min, wash it;

[0035] S2 is crushed, and the tortoise shell cleaned by S1 is frozen at -48°C, crushed at a low temperature, ground, and passed through an 80-mesh sieve to obtain tortoise shell powder;

[0036] S3 extraction: add water to the tortoise shell powder obtained in S2, boil the glue juice, add 1.4 times of water for the first time, boil the glue juice for 5 hours, fi...

Embodiment 2

[0044] Raw material ratio:

[0045] Tortoise shell 250kg, soybean oil 2.6kg, rock sugar 2.4kg, rice wine 1.0kg

[0046] Preparation Process:

[0047] S1 Tortoise shell pre-treatment: Select a dry tortoise shell, use 50% NaOH solution to smear the carrion of the tortoise shell, the smear is based on the full coverage, after ultrasonic treatment with a frequency of 200KHz for 5 minutes, microwave treatment with a power of 0.5KW for 1 minute, take it out, and then Repeat the above operation 2 times, after the last microwave treatment, put it into clean water, after 100KHz ultrasonic treatment for 5min, wash;

[0048] S2 is crushed, and the tortoise shell cleaned by S1 is frozen at -48°C, crushed at a low temperature, ground, and passed through an 80-mesh sieve to obtain tortoise shell powder;

[0049] S3 extraction: add water to the tortoise shell powder obtained in S2, boil the glue juice, add 1.2 times of water for the first time, boil the glue juice for 3 hours, filter the g...

Embodiment 3

[0057] Raw material ratio:

[0058] Tortoise shell 250kg, soybean oil 2.6kg, rock sugar 2.4kg, rice wine 1.0kg

[0059] Preparation Process:

[0060] S1 Tortoise shell pre-treatment: Select a dry tortoise shell, use 20% NaOH solution to smear the carrion of the tortoise shell, and the smear is based on the full coverage. After ultrasonic treatment with a frequency of 80KHz for 5 minutes, microwave treatment with a power of 8KW for 2 minutes, take it out, and repeat. The above operation was performed twice, after the last microwave treatment, put it into clean water, and after 100KHz ultrasonic treatment for 5 minutes, wash it;

[0061] S2 is crushed, and the tortoise shell cleaned by S1 is frozen at -48°C, crushed at a low temperature, ground, and passed through an 80-mesh sieve to obtain tortoise shell powder;

[0062] S3 extraction: add water to the tortoise shell powder obtained in S2, boil the glue juice, add 1.6 times of water for the first time, boil the glue juice for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com