Catalyst for simultaneous denitration and demercuration on smoke gas as well as preparation method and application thereof

A catalyst and flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of high catalytic activity, high cost, toxicity, etc., and achieve the effect of good removal efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

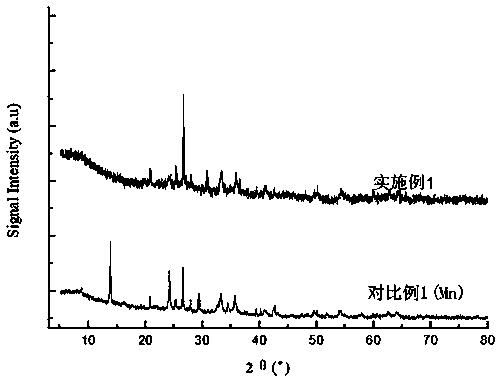

Embodiment 1

[0027] (1) Preparation of dealkalized red mud

[0028] Pass the dried red mud through a 200-mesh sieve and transfer it to a polytetrafluoroethylene-lined hydrothermal reactor, and add it into the mixed acid solution according to the amount of 1g red mud / 10mL acid solution, wherein the mixed acid solution is composed of 3mol / L hydrochloric acid and Nitric acid is mixed according to the volume ratio of 1:5. The hydrothermal reactor was crystallized at 90°C for 12 hours, washed with deionized water for 3 to 5 times, filtered, and dried in an oven at 100°C. Marked as ARM-1.

[0029] (2) Preparation of catalyst

[0030] The acidified dealkalized red mud was impregnated with Mn(NO 3 ) 2 solution (0.5mol / L), stirred at room temperature for 4 h, dried in an oven at 80 °C for 24 h, and calcined at 500 °C for 4 h to obtain a 3wt% Mn-ARM-1 catalyst. Press the powder catalyst into tablets, grind and screen 40-60 mesh particles to obtain MnO x Modified red mud catalyst.

[0031] (3)...

Embodiment 2

[0034] Prepare MnO according to the method of embodiment 1 x The difference of the modified dealkalized red mud catalyst is that the hydrothermal crystallization temperature is changed to 60°C, and the obtained catalyst is marked as 3wt.% Mn-ARM-2.

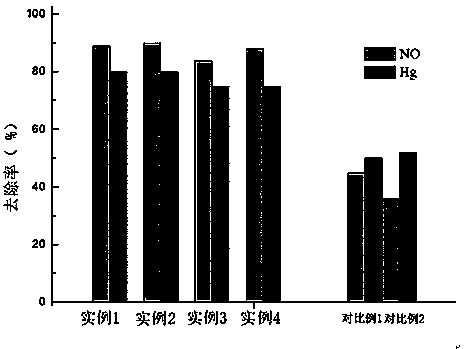

[0035]Catalyst carries out active measurement on the device described in above-mentioned embodiment 1, and the result shows that the catalyst that embodiment 2 makes is 550ppm to NO concentration, Hg 0 Concentration is 50µgL -1 gas (the remaining gas composition is 5% O 2 , 550ppmNH 3 and balance gas N 2 ), at 230°C, at a reaction space velocity of 80,000 h -1 Under these conditions, the removal efficiency of NO exceeds 90%, and the oxidation removal efficiency of Hg exceeds 80%.

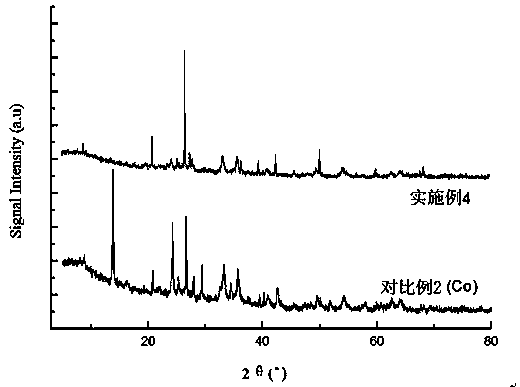

Embodiment 3

[0037] Prepare MnO according to the method of Example 1 x The difference of the modified dealkalized red mud catalyst is that the hydrothermal crystallization temperature is changed to 120°C, and the obtained catalyst is marked as 3wt.% Mn-ARM-3.

[0038] Catalyst carries out activity measurement on the device described in above-mentioned embodiment 1, and the result shows that the catalyst that embodiment 3 makes is 550ppm to NO concentration, Hg 0 Concentration is 50µgL -1 gas (the remaining gas composition is 5% O 2 , 550ppmNH 3 and balance gas N 2 ), at 230°C, at a reaction space velocity of 80,000 h -1 Under this condition, the removal efficiency of NO exceeds 84%, and the oxidation removal efficiency of Hg exceeds 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com