Catalyst for reductive amination of isophorone nitrile to synthesize isophorone diamine and preparation method and applications thereof

A technology of isophorone diamine and isophorone nitrile is applied in the field of catalysts to achieve high yield and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

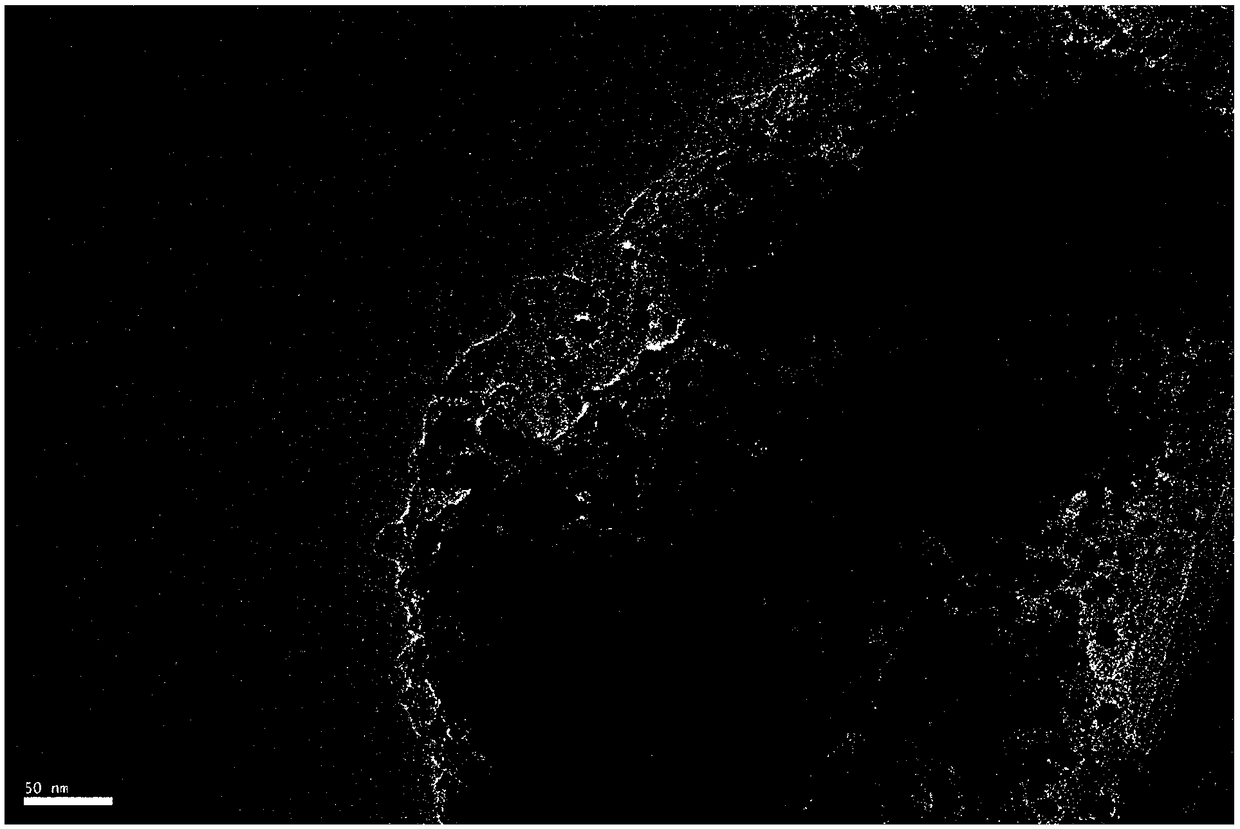

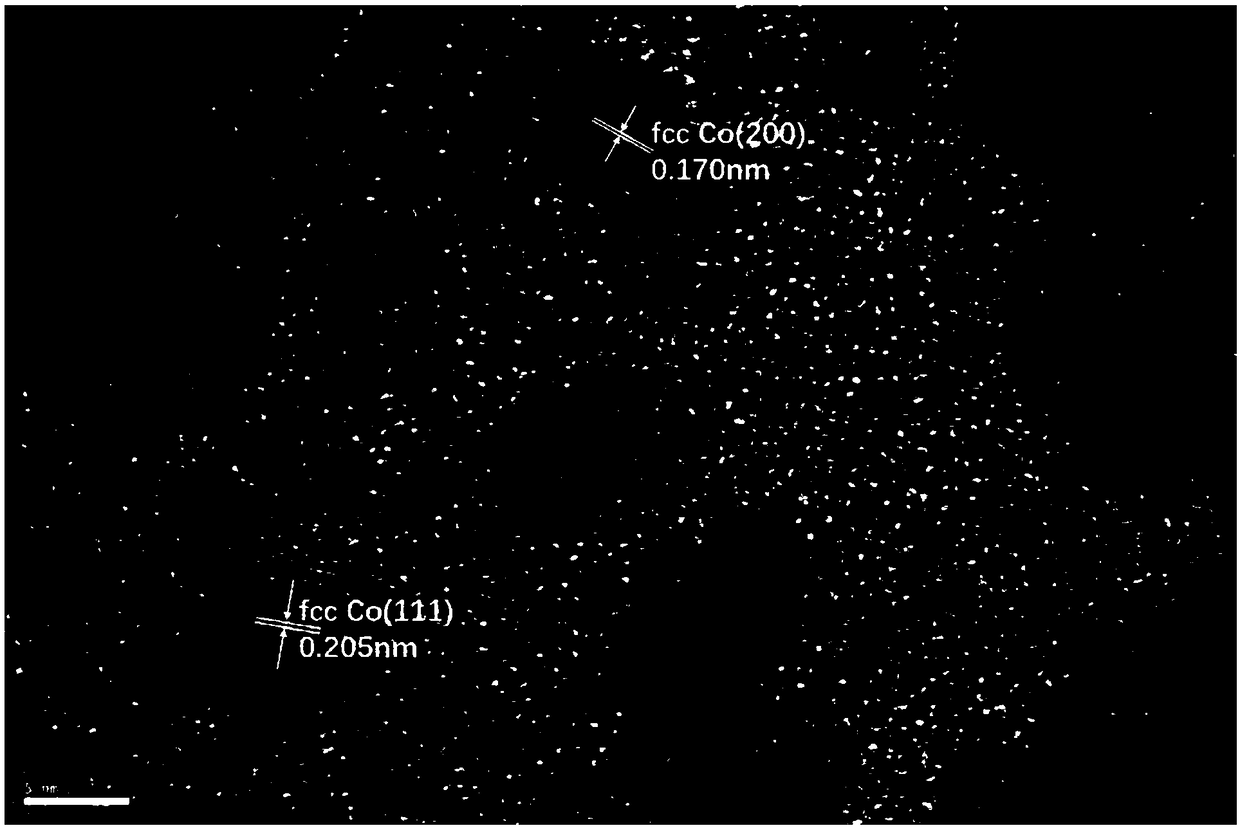

Image

Examples

Embodiment 1

[0039] (1) Preparation of Co metal / activated carbon (AC) catalyst by isometric impregnation method

[0040] First calculate the saturated water absorption of the activated carbon (AC) carrier, and calculate the quality of the required cobalt salt as required (in terms of the total mass of the catalyst, the Co metal loading is 20%), and the cobalt salt is fully and uniformly dissolved in water, Slowly add a certain mass of carrier, impregnate with an equal volume for 24 hours, place it in a vacuum oven at 110°C for 10 hours to dry to obtain a catalyst precursor, and finally roast the catalyst precursor at 500°C for 3 hours in a nitrogen atmosphere to obtain a Co metal / activated carbon catalyst.

[0041] (2) Catalytic reductive amination of isophorone nitrile to synthesize isophorone diamine

[0042] Reaction is carried out in reactor, in still, add Co metal / activated carbon catalyst and solvent methanol prepared by isophorone nitrile, step (1), wherein the mass volume ratio of ...

Embodiment 2

[0047]The test was carried out in a reaction kettle, and isophoronenitrile, catalyst Raney Co and solvent methanol were added to the kettle, wherein the mass volume ratio of isophoronenitrile and solvent methanol was 1kg: 16L, and the catalyst Raney Co accounted for the proportion of the reactant isophoronenitrile. The quality of ketone nitrile is 52%, and reaction temperature is 80 ℃, and reaction time is 8h, and reaction pressure is 8.2Mpa, and wherein ammonia partial pressure is 0.2MPa, and hydrogen partial pressure is 8MPa, after reaction finishes, quench with water, cool to room temperature, sampled, and detected by gas chromatography.

[0048] Tested:

[0049] The conversion rate of isophorone nitrile was 100%, the selectivity of isophorone diamine was 80.4%, and the yield of isophorone diamine was 80.4%.

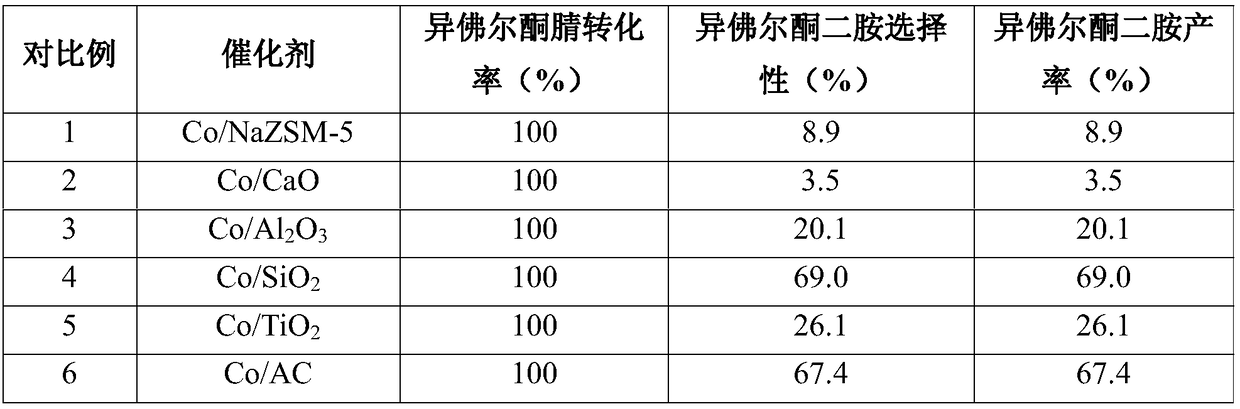

[0050] In the synthesis of isophoronediamine by one-pot catalytic reductive amination of isophoronenitrile, the Co metal / activated carbon catalyst was compared with ...

Embodiment 3~7

[0058] The preparation process of the catalyst is the same as that in Example 1, the only difference is the loading amount of Co metal, which is specifically listed in Table 2 below.

[0059] Catalyzing the reductive amination of isophorone nitrile to synthesize isophorone diamine. The isophoronenitrile conversion, isophoronediamine selectivity and yield are listed in Table 2 below.

[0060] Table 2

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com