Preparation method of magnesium L-ascorbyl phosphate without any organic solvent residue

A technology of magnesium ascorbyl phosphate and organic solvents, applied in the field of biopharmaceuticals, can solve problems such as environmental pollution, affecting product quality, and difficulty in use, and achieve the effects of reducing production costs and improving dissolution rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

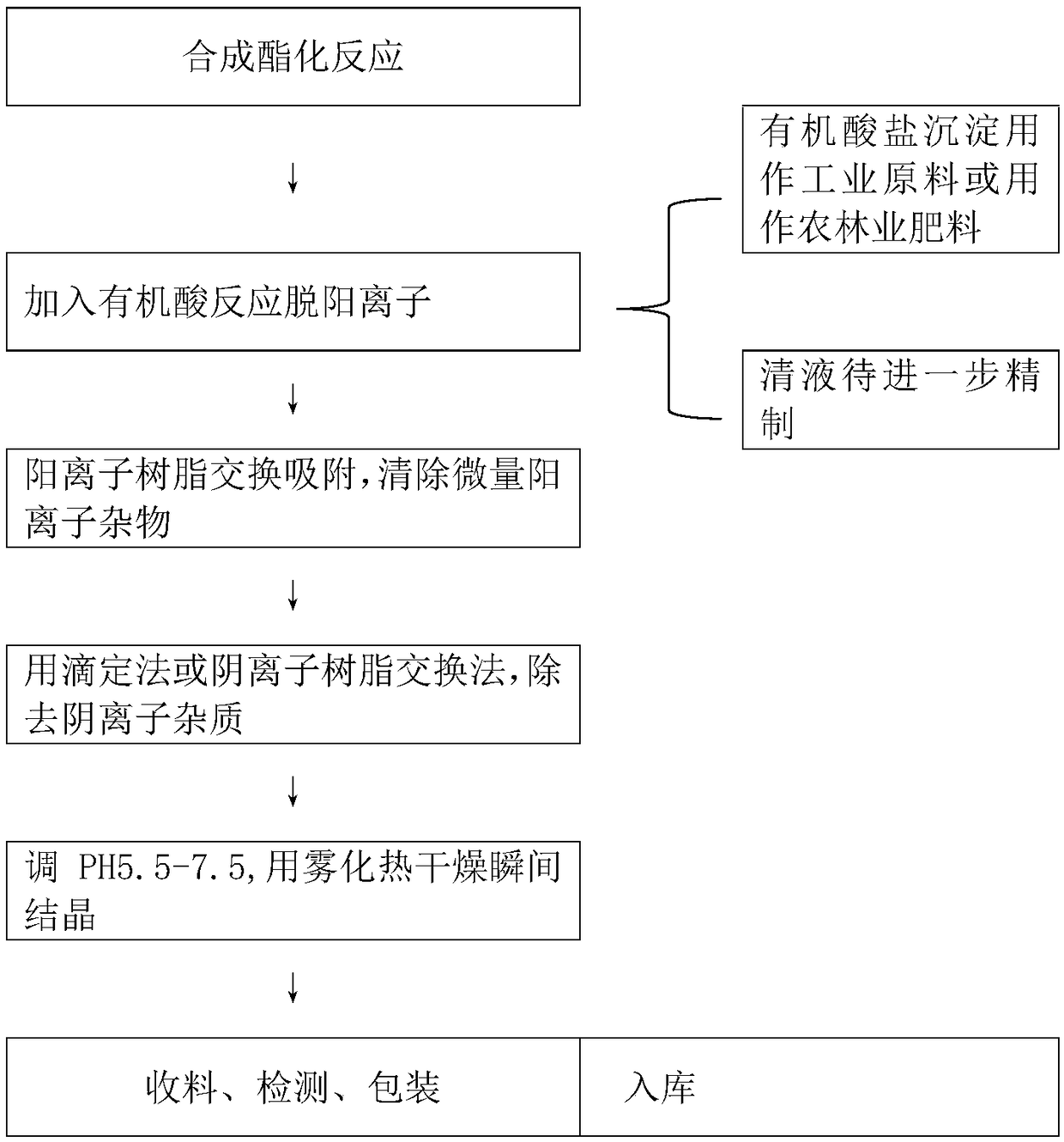

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Add oxalic acid to the L-ascorbyl phosphate crude product after the synthetic reaction according to the amount of VC input during the synthetic esterification reaction, take VC as 1 mass part, oxalic acid as 0.1-0.25 mass part, and decalcify , according to the concentration of crude L-ascorbyl phosphate, add deionized water in an appropriate amount, so that the concentration of the feed solution after decalcification of the organic acid is controlled at 1.0%, and the feed solution after decalcification is pumped into the ion resin exchange column at a speed of 0.1m Minutes, exchange and remove the cations;

[0017] The anion content of the treated feed liquid is measured to determine the amount of anion resin, and then it is treated with D008 macroporous strong base acrylic anion exchange resin to remove free phosphate and sulfate. This process needs to strictly determine the anion content to Determine the consumption of anion resin, guarantee the quality ...

example 2

[0022] Add oxalic acid to the crude product of L-ascorbyl phosphate after the synthesis reaction by the amount of VC input during the synthesis esterification reaction, take VC as 1 mass part, oxalic acid as 0.25-0.45 mass part, and carry out decalcification according to L - Add deionized water in an appropriate amount to the concentration of the crude product of ascorbyl phosphate, so that the concentration of the feed solution after decalcification of the organic acid is controlled at 15%. the cation;

[0023] The anion content of the treated feed liquid is measured to determine the amount of anion resin, and then it is treated with D008 macroporous strong base acrylic anion exchange resin to remove free phosphate and sulfate. This process needs to strictly determine the anion content to Determine the consumption of anion resin, guarantee the quality of L-magnesium ascorbyl phosphate feed solution before atomization drying crystallization.

[0024] After the fine filtration...

example 3

[0027] Example 3: drop into the consumption of VC during synthetic esterification reaction, add oxalic acid in the crude product of L-ascorbyl phosphate after synthetic reaction, take by weighing VC as 1 mass part, oxalic acid is 0.6-0.8 mass part, decalcify, Deionized water can be added in an appropriate amount according to the concentration of the crude L-ascorbyl phosphate, so that the concentration of the feed solution after decalcification of the organic acid is controlled at 20%. exchange to remove cations;

[0028] The anion content of the treated feed liquid is measured to determine the amount of anion resin, and then it is treated with D008 macroporous strong base acrylic anion exchange resin to remove free phosphate and sulfate. This process needs to strictly determine the anion content to Determine the consumption of anion resin, guarantee the quality of L-magnesium ascorbyl phosphate feed solution before atomization drying crystallization.

[0029] After the fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com