Anti-bacterial polyolefin and preparation method thereof

A technology of polyolefin and polyolefin resin is applied in the field of antibacterial polyolefin and its preparation, which can solve the problems of affecting antibacterial properties, agglomeration of nano antibacterial agents, etc., and achieve the effects of improving antibacterial activity, avoiding agglomeration, and reducing the degree of harm and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

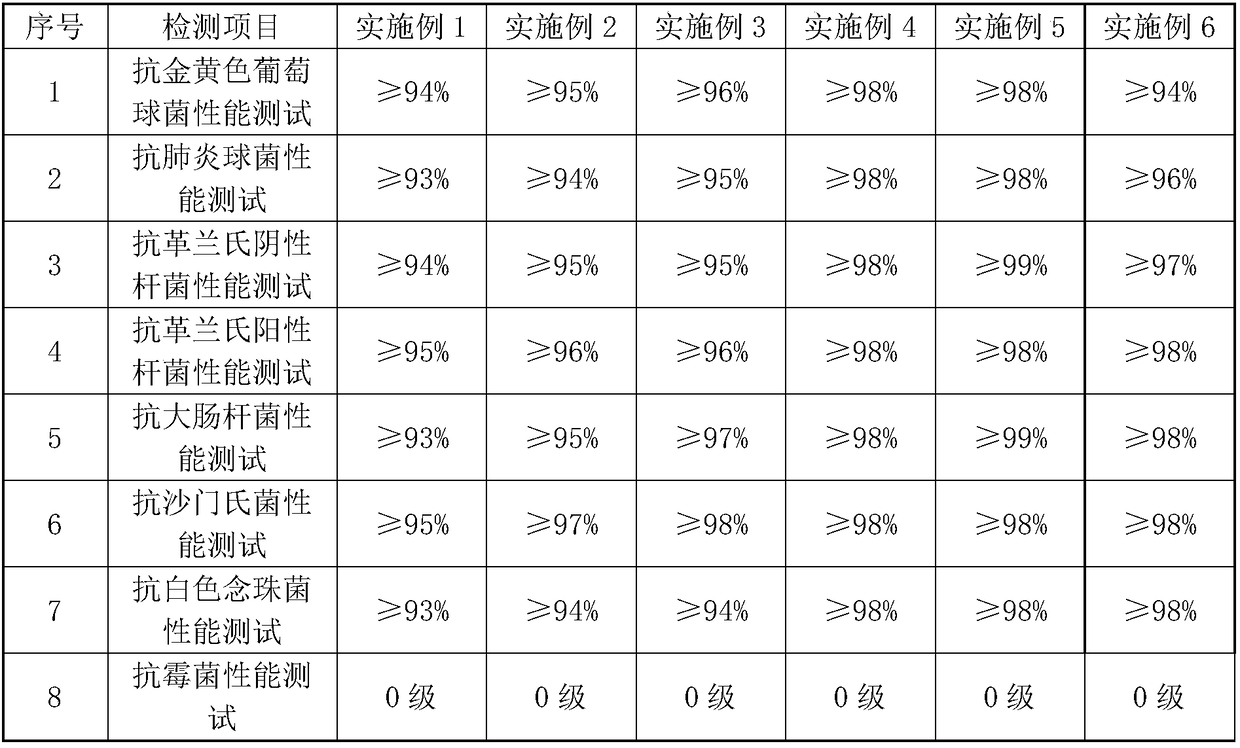

Examples

Embodiment 1

[0035] 100 parts (parts by weight) of homopolypropylene resin, 0.2 part of graphene oxide / nanometer silver, 0.1 part of tetrakis [β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol ester (anti- Oxygen agent 1010) was added into the high mixer together, and mixed at a speed of 300 rpm for 5 minutes; the mixed blend was extruded and granulated by a twin-screw extruder to obtain an antibacterial polyolefin.

Embodiment 2

[0037] 100 parts (parts by weight) of copolymerized polypropylene resin, 0.3 part of graphene oxide / nanometer silver, and 1 part of tris-(2,4-di-tert-butylphenyl) phosphite (antioxidant 168) were added to the high-mixing In the machine, mix at a speed of 300 rpm for 6 minutes; extrude and granulate the mixed blend through a twin-screw extruder to obtain an antibacterial polyolefin.

Embodiment 3

[0039] 100 parts (parts by weight) of copolymerized polypropylene resin, 0.4 part of graphene oxide / nanometer silver, 0.5 part of tetrakis [β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant Add agent 1010) into the high mixer together, and mix at a speed of 300 rpm for 8 minutes; extrude the mixed blend through a twin-screw extruder to obtain antibacterial polyolefin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com