Composite modifying and flooding agent

A compound technology of adjusting and flooding agent, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of under-injection of water injection wells, the water injection volume cannot reach the daily water injection volume, and the production decline of effective oil wells and well groups, etc. problems, to achieve the effect of improving the oil displacement effect, increasing the amount of water injection, and reducing the amount of injected water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

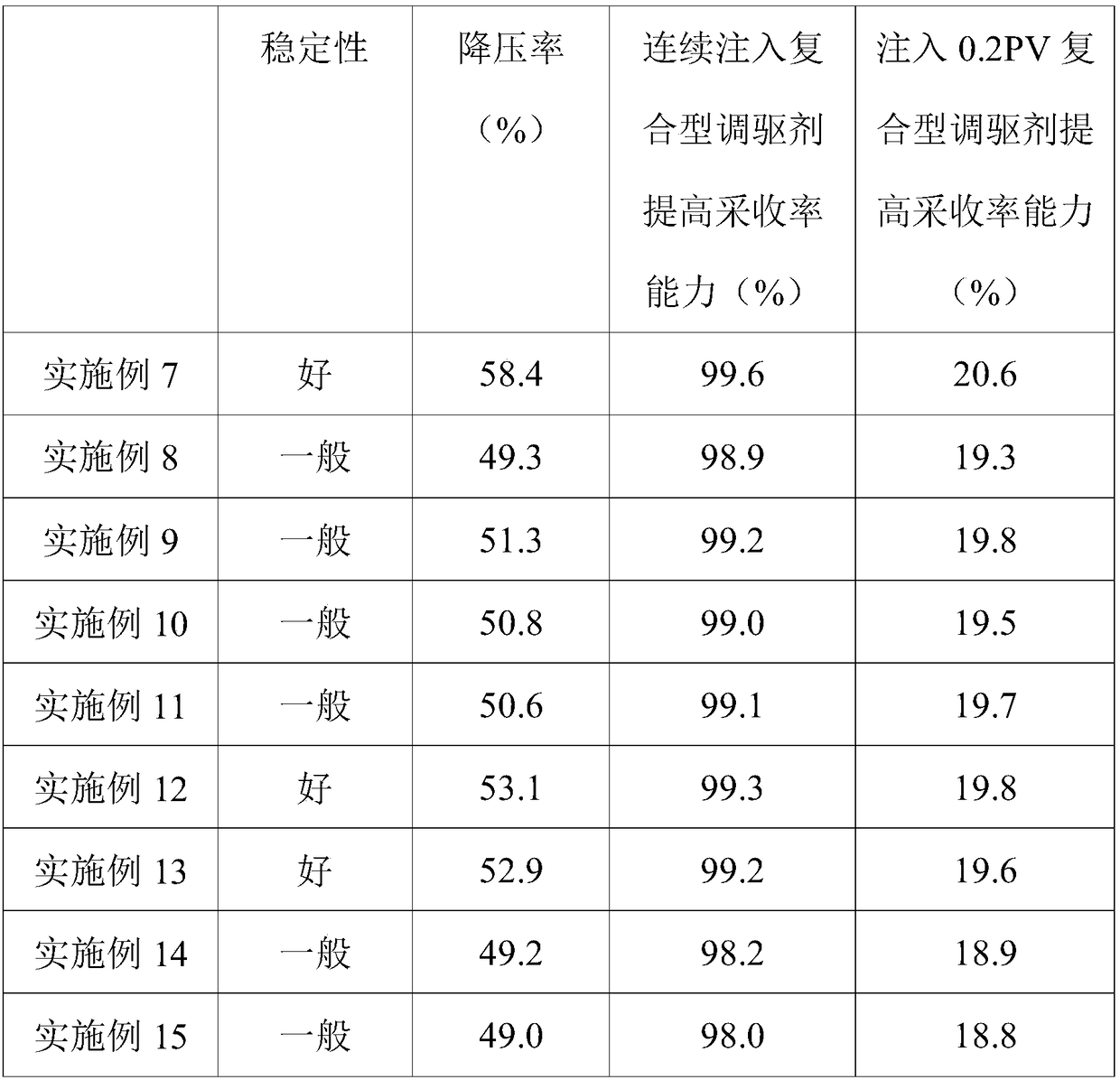

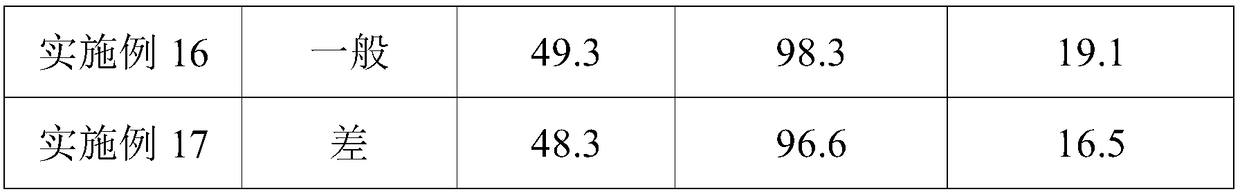

Examples

Embodiment 1

[0038] The invention provides a composite control and flooding agent, which comprises 20-50 parts of a surfactant-type plugging agent, 30-70 parts of a pressure-reducing and increasing injection agent, and 5 parts of a particle plugging agent in parts by weight. -20 parts; wherein, the surfactant-type blocking agent is composed of polyacrylamide, water, composite crosslinking agent, modified cyclodextrin, m-phenylenediamine, oxygen scavenger and carboxylate gemini surfactant by weight Ratio 1: (110-131): (0.05-0.12): (0.2-0.8): (0.1-0.3): (0.05-0.2): (0.3-1) ratio prepared.

[0039] The present invention utilizes three key materials for coupling regulation and displacement of surfactant-type plugging agent, pressure-reducing and increasing injection agent, and granular plugging agent to carry out an effective combination of water plugging and profile control technology and pressure-reducing and increasing-injection technology to realize water plugging and profile control, reduc...

Embodiment 2

[0041] On the basis of Example 1, the raw materials for the preparation of the surfactant-type plugging agent include polyacrylamide, composite crosslinking agent, modified cyclodextrin, m-phenylenediamine, oxygen scavenger, carboxylate gemini surfactant agent. Among them, the polyacrylamide is a widely used raw material for conventional water plugging and profile control agents. When its molecules meet the oil phase, they shrink and curl, while when they meet the water phase, their molecular chains stretch, expand and stagnate water, with good selectivity. However, since this type of polymer and the formation mainly rely on hydrogen bond adsorption, the adsorption strength is weak, and it cannot withstand the erosion of water. In addition, the formation water has a high degree of salinity, and the polyacrylamide has a weak anti-salt effect, and the salt neutralizes the polyacrylamide group. The charge on the polyacrylamide ion group is shielded, the electrostatic repulsion be...

Embodiment 3

[0047] On the basis of embodiment 2, described carboxylate gemini surfactant comprises carboxylate gemini surfactant A and carboxylate gemini surfactant B, and described carboxylate gemini surfactant A consists of 1,3 - propane sultone, absolute ethanol, p-phenylenediamine, methanol, anhydrous potassium carbonate, bromododecane, acetone by weight ratio 1: (4-8): (0.3-0.7): (8- 12): (1-1.3): (0.8-1.2): (3-6) ratio prepared; the preparation method of the carboxylate gemini surfactant A comprises the following steps: first add Stir the formulated amount of 1,3-propane sultone, absolute ethanol, and p-phenylenediamine, heat up to 55-60°C, keep the temperature for 20-25 hours, and concentrate to dryness under reduced pressure; then add the formulated amount of methanol in sequence , anhydrous potassium carbonate, bromododecane, heated up to 60-70°C, kept warm for 30-35h, filtered, and the filtrate was concentrated to dryness under reduced pressure; finally, recrystallization was ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com