Manufacturing method and application of oxide semiconductor thin film

A technology of oxide semiconductors and production methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve the problems of unfavorable preparation of high-performance thin-film transistors and poor performance of thin-film transistors, and avoid vacuum equipment and photolithography. process, meeting high pixel requirements, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]This embodiment provides a method for fabricating an oxide semiconductor thin film, which includes the following steps:

[0046] S1. Perform hydrophobic treatment on the substrate to obtain a modified substrate.

[0047] Generally speaking, after the substrate is cleaned, it can be modified by hexamethyldisilazine (HMDS for short), that is, hydrophobized, and a modified substrate with a contact angle of 52°±4° can be obtained.

[0048] In this embodiment, a silicon wafer containing thermally oxidized silicon dioxide with a thickness of 300 nm is specifically selected as the substrate; other optional materials for the substrate will not be described in detail here, and those skilled in the art can refer to the prior art to select according to specific requirements. Can.

[0049] S2. Prepare electronic ink.

[0050] Specifically, functional reagents are added to the precursor solution of the oxide semiconductor to obtain electronic ink. Among them, the functional reagen...

Embodiment 2

[0074] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between Example 2 and Example 1 is that in step S2, the concentration of PVP 1300000 in the electronic ink is 0.05mg / mL, and the precursor solution of the oxide semiconductor is 0.02mol / L In(NO 3 ) 3 aqueous solution.

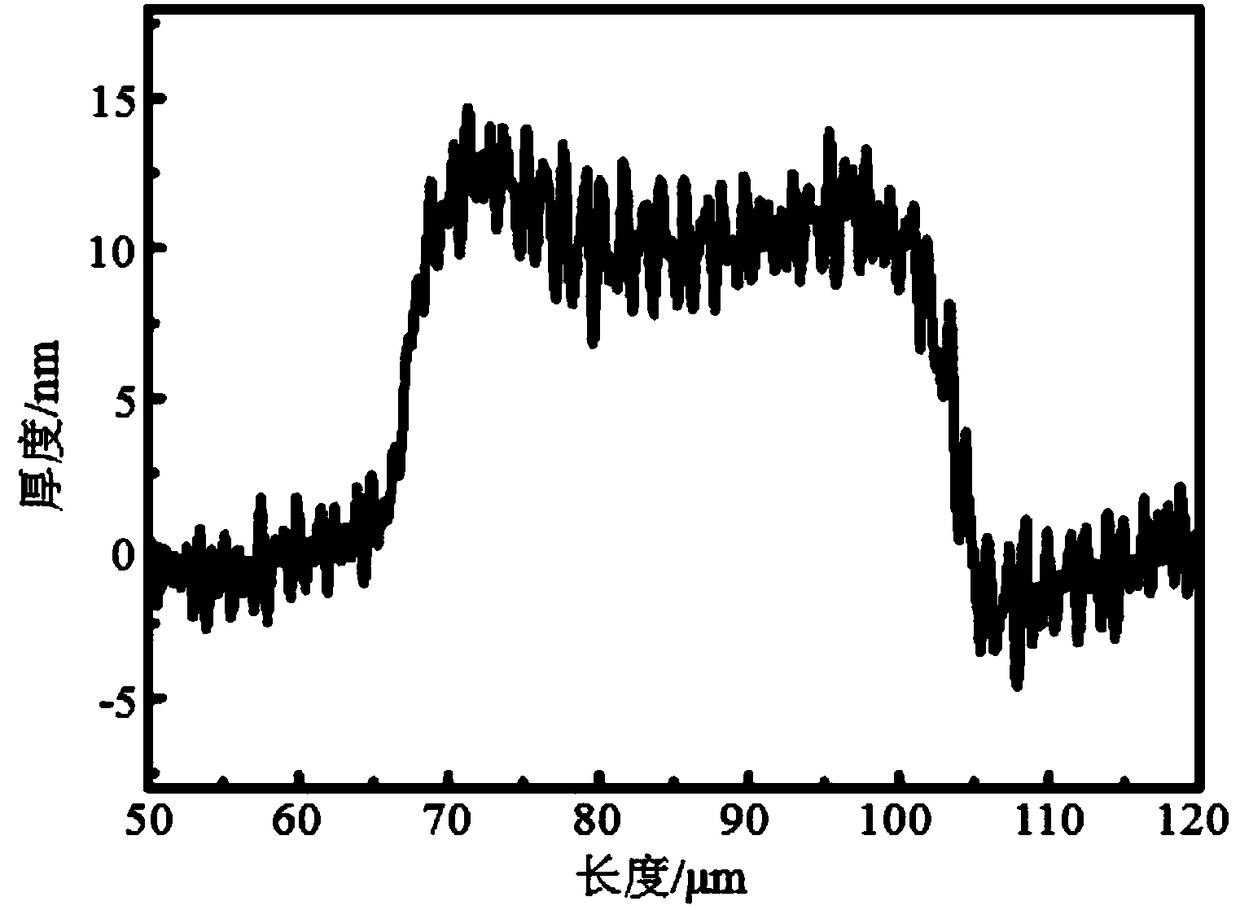

[0075] The oxide semiconductor thin film array obtained in this example has an optical physical map and a film topography map equivalent to those of the oxide semiconductor thin film array in Example 1.

Embodiment 3

[0077] Based on the fabrication method of the oxide semiconductor thin film provided in the above-mentioned embodiment 1 and embodiment 2, a small-sized and thin oxide semiconductor thin film can be fabricated, which can be applied in the field of oxide thin film transistors as active transistors therein. layer to obtain high-performance oxide thin film transistors.

[0078] Specific reference Figure 9 , the oxide thin film transistor provided in this embodiment is a bottom-gate type; the oxide thin film transistor includes a gate 11, a dielectric layer 12, an active layer 13 that are sequentially stacked, and an A source 14 and a drain 15 at both ends, both of which are in contact with the dielectric layer 12 .

[0079] Specifically, the active layer 13 is formed of a small-sized, thin-thick oxide semiconductor film.

[0080] Hereinafter, the method for fabricating the bottom-gate oxide thin film transistor of this embodiment will be described in detail; the method for fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com