High-energy lithium-battery anode pulp and preparation method thereof

A negative electrode slurry and lithium battery technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of electrode material powdering and falling off, high crystallinity, and high brittleness, and achieve low swelling rate, high content, and maintenance good form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

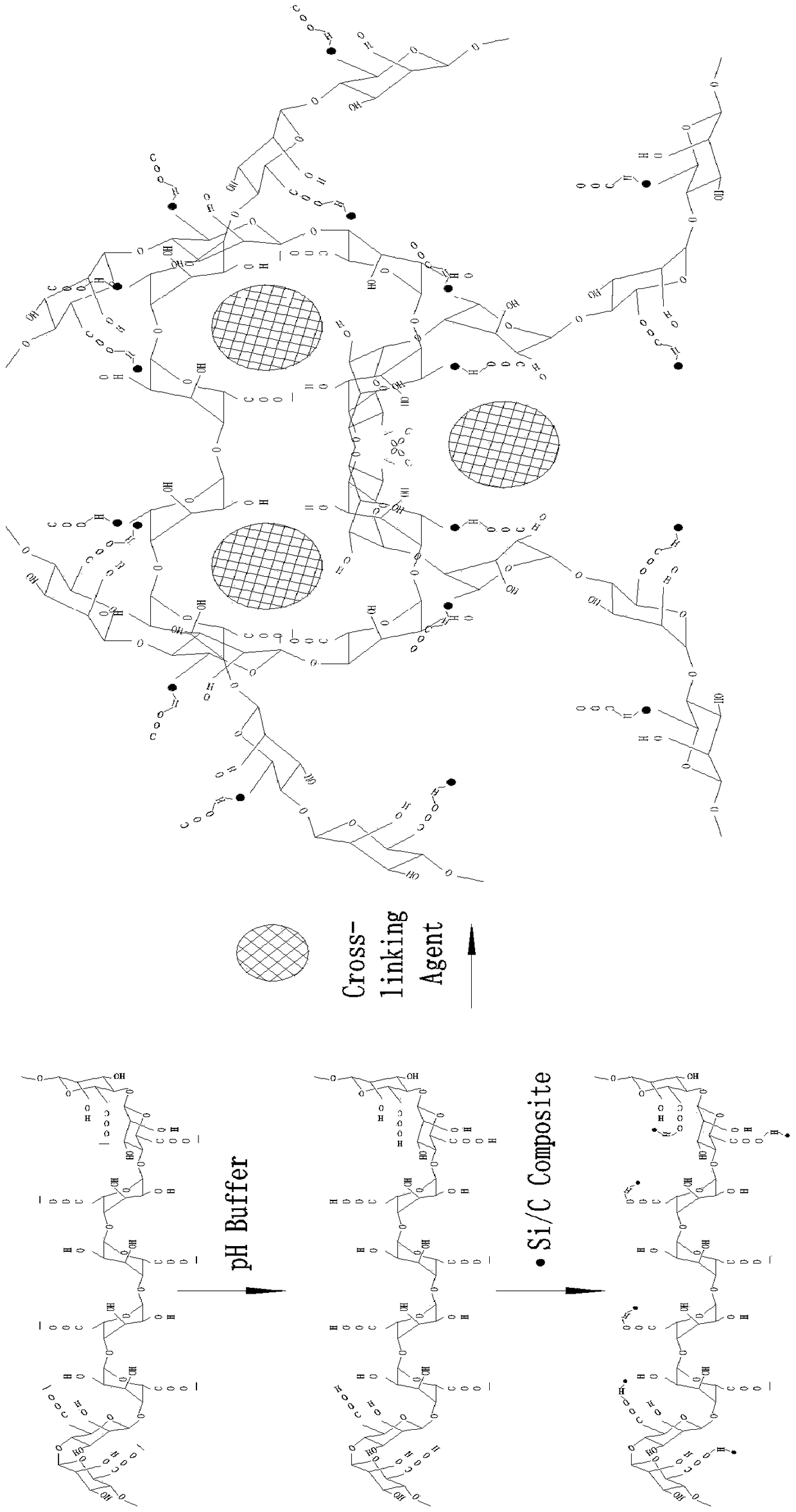

Method used

Image

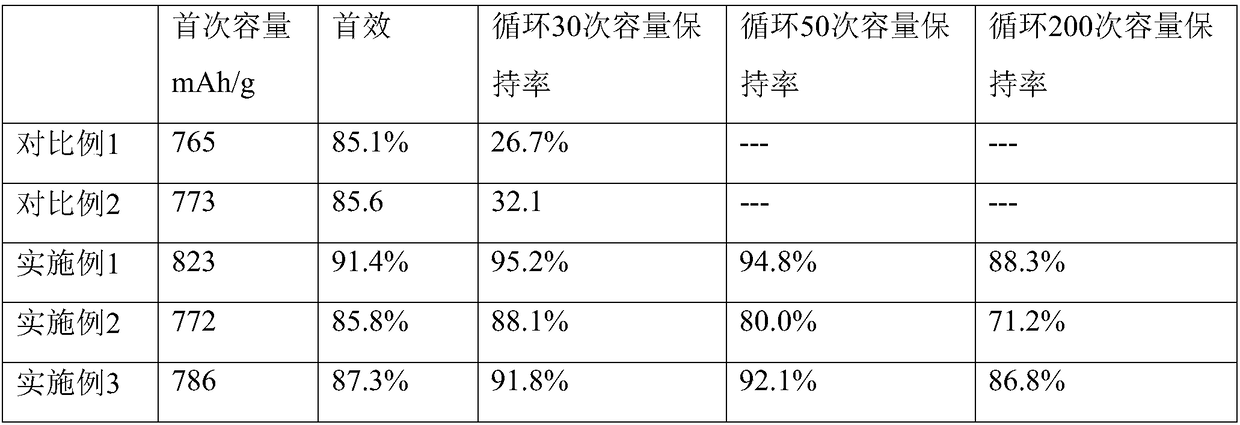

Examples

Embodiment 1

[0023] Embodiment 1 A kind of high-energy lithium battery negative electrode slurry

[0024] (1) The formula quantity is: 100 parts of silicon carbon active material (coated with silica graphite, silicon content 15%), 2 parts of conductive agent (carbon black), 7 parts of sodium alginate, crosslinking agent (containing Ca 2+ aqueous solution) 5 parts, buffer solution 15 parts, deionized water 15 parts; the buffer solution has a pH value of 3.

[0025] (2) Preparation method:

[0026] 1) Add 7 parts of sodium alginate to 15 parts of buffer solution and stir for 1 hour to obtain mixture A.

[0027] 2) Dissolve 5 parts of cross-linking agent into 15 parts of deionized water to obtain solution B.

[0028] 3) Take 100 parts of silicon carbon active material and 2 parts of conductive agent and dry mix for 30 minutes, add 70% mixture A, stir for 45 minutes, add the remaining mixture A, stir for 2 hours, add solution B and stir for 1 hour, add water to adjust the viscosity , to obt...

Embodiment 2

[0030] Embodiment 2 A kind of high-energy lithium battery negative electrode slurry

[0031] (1) The formula quantity is: 100 parts of silicon carbon active material (coated with silica graphite, silicon content 15%), 0.5 part of conductive agent (carbon black), 2 parts of sodium alginate, crosslinking agent (containing Sr 2+ aqueous solution) 3 parts, buffer solution 15 parts, deionized water 15 parts; the buffer solution has a pH value of 2.

[0032] (2) Preparation method:

[0033] 1) Add 2 parts of sodium alginate to 7 parts of buffer solution and stir for 1 hour to obtain mixture A.

[0034] 2) Dissolve 3 parts of cross-linking agent into 10 parts of deionized water to obtain solution B.

[0035] 3) Take 100 parts of silicon carbon active material and 0.5 part of conductive agent and dry mix for 30 minutes, add 70% of mixture A, stir for 45 minutes, add the remaining mixture A, stir for 2 hours, add solution B and stir for 1 hour, add water to adjust the viscosity , to...

Embodiment 3

[0036] Embodiment 3 A kind of high-energy lithium battery negative electrode slurry

[0037] (1) The formula quantity is: 100 parts of silicon carbon active material (coated with silica graphite, silicon content 15%), 5 parts of conductive agent (carbon nanotube), 10 parts of sodium alginate, crosslinking agent (containing Ca 2+ aqueous solution) 8 parts, buffer solution 25 parts, deionized water 20 parts; the buffer solution has a pH value of 4.

[0038] (2) Preparation method:

[0039] 1) Add 10 parts of sodium alginate to 25 parts of buffer solution and stir for 1 hour to obtain mixture A.

[0040] 2) Dissolve 8 parts of cross-linking agent into 20 parts of deionized water to obtain solution B.

[0041]3) Take 100 parts of silicon carbon active material and 5 parts of conductive agent and dry mix for 30 minutes, add 70% mixture A, stir for 45 minutes, add the remaining mixture A, stir for 2 hours, add solution B and stir for 1 hour, add water to adjust the viscosity , to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com