A method and system for removing tar

A technology of tar and reactor, which is applied in the field of mineral circulation for tar removal, and can solve problems such as undesired shutdown, blockage of tar particles, loss of multiple heat recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

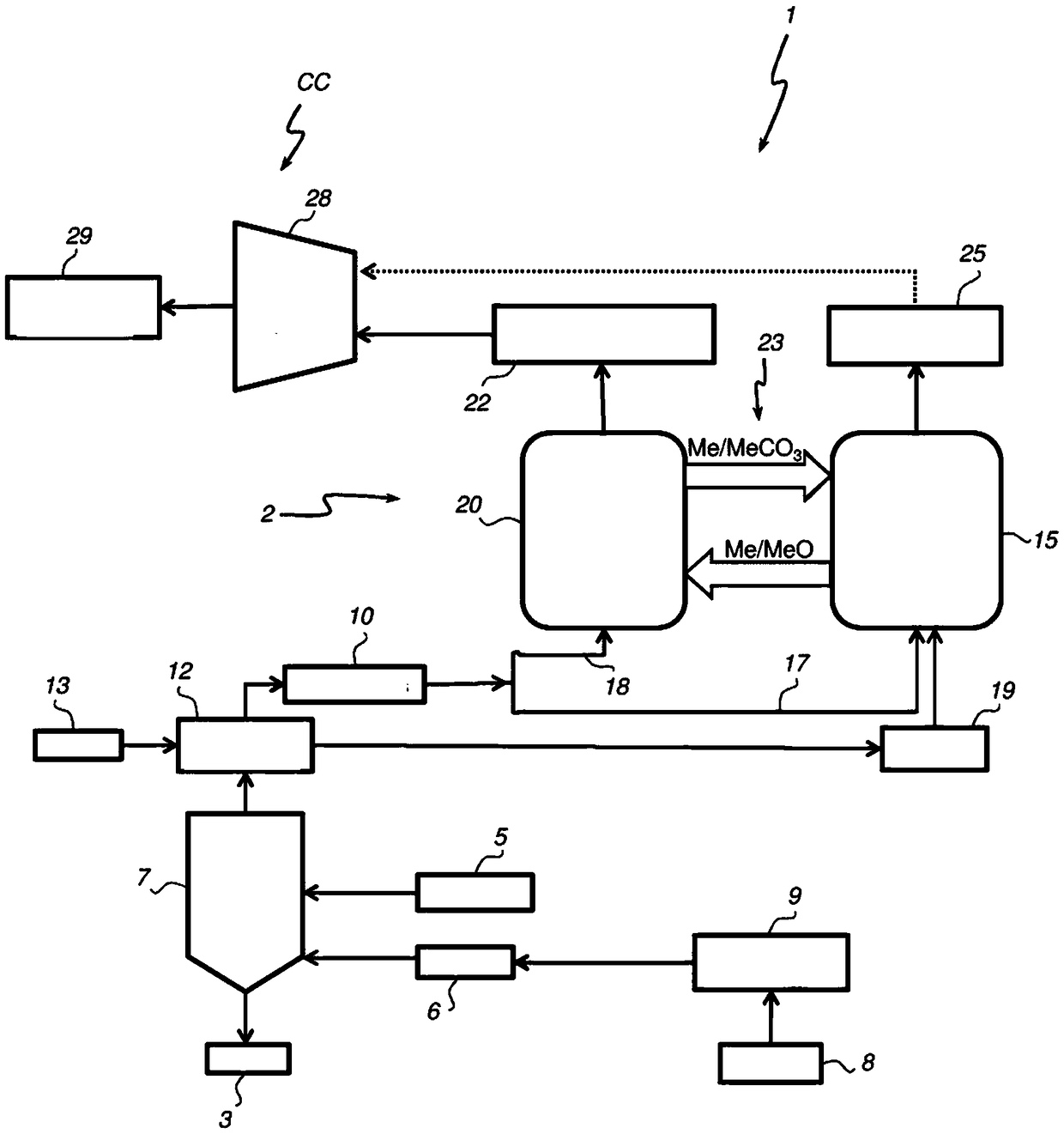

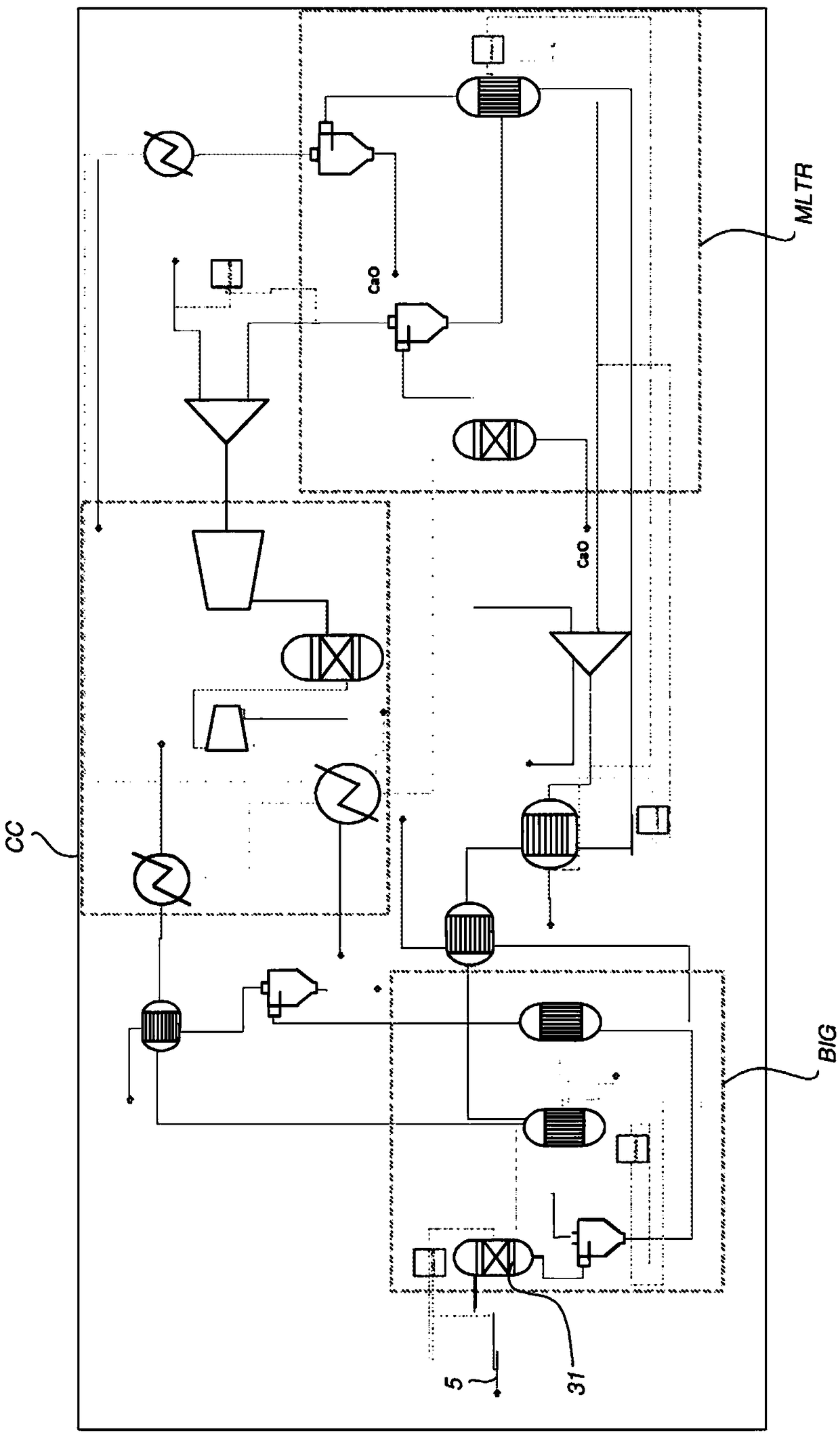

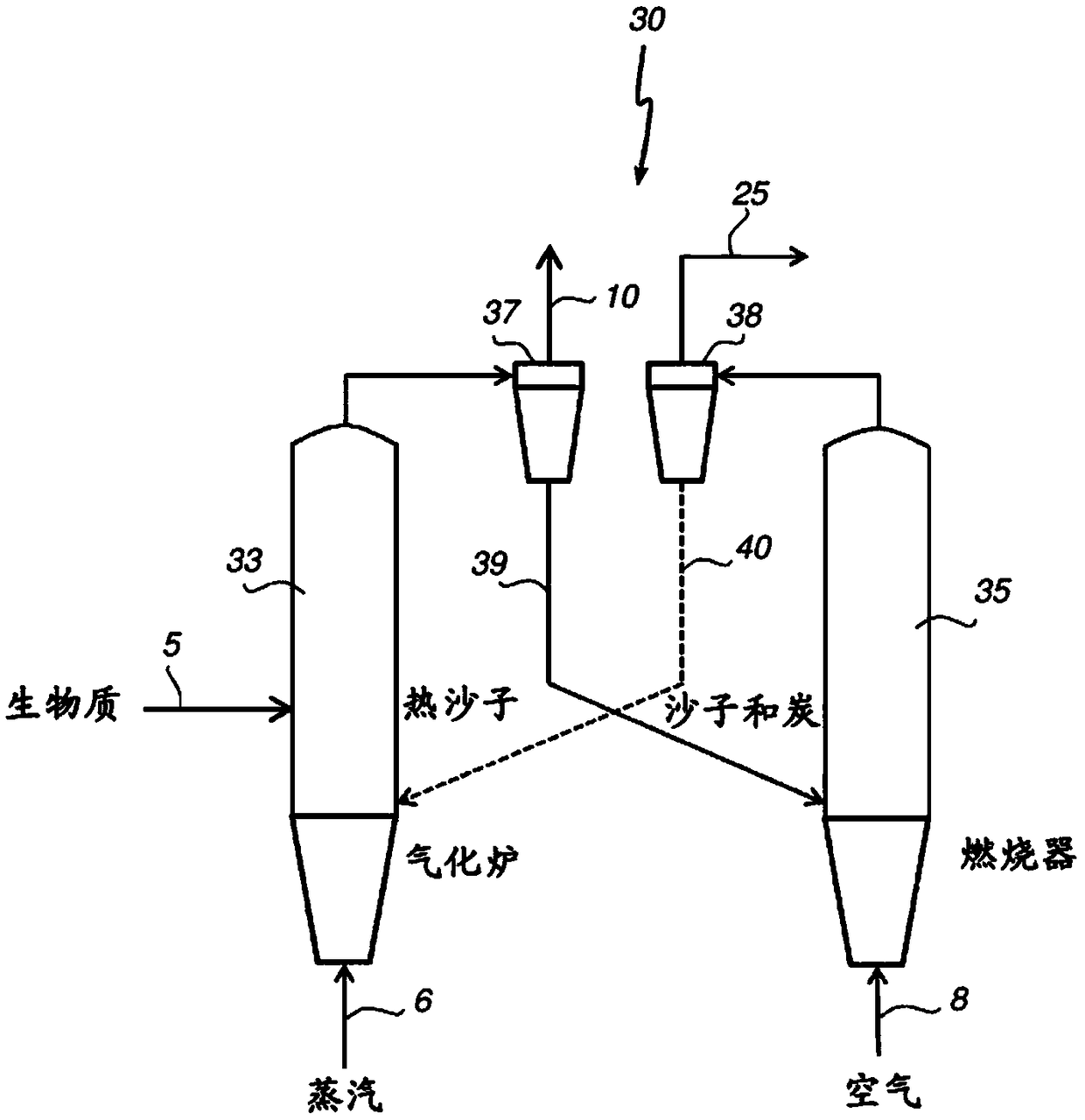

[0052] The invention will now be described with reference to the following examples, which should be considered in all respects as illustrative and not restrictive. In the figures, corresponding features in the same embodiment or common to different embodiments have been given the same reference numerals.

[0053] Biomass gasification is a process of converting carbonaceous fuels into synthesis gas (or the familiar term syngas) via thermochemical routes. To benefit downstream energy / power conversion processes, the syngas produced should ideally have a high lower heating value (LHV). However, the synthesis gas quality is affected by the use of different gasification agents. For example, biomass gasification using air as the gasification agent produces only about 4.4 MJ / m 3 Syngas with low LHV, while using pure oxygen, can obtain higher LHV (~9.6MJ / m 3 ). However, the use of pure oxygen as the gasification agent requires additional costs associated with the air separation un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com