Manufacturing method of gravure plate roller with zinc coating

A technology of gravure plate roll and production method, which is applied in the direction of manufacturing tools, decorative arts, processing models, etc., can solve the problems of complex gravure plate roll production process, long process flow, and increased nickel plating, etc., to speed up market response time, simplification of the manufacturing process, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

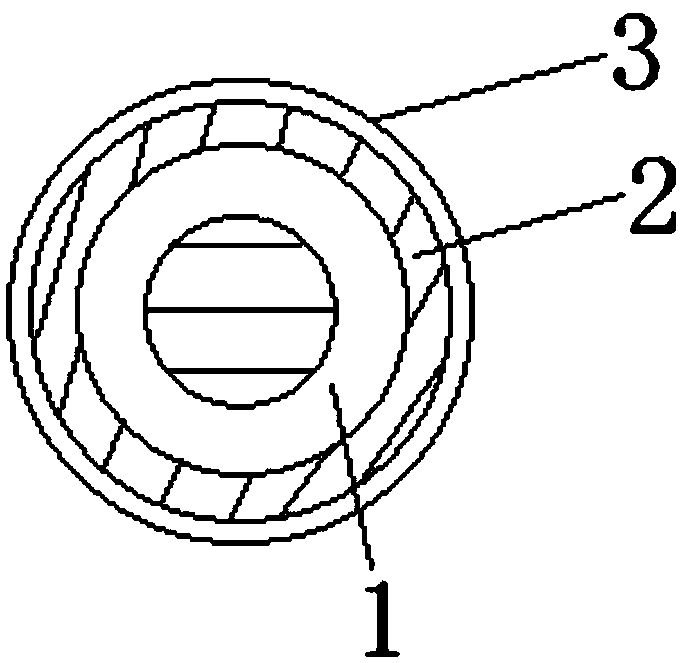

[0040] like figure 1 The illustrated gravure roll containing a galvanized layer includes a steel roll 1 , a galvanized layer 2 provided on the surface of the steel roll 1 , and a chrome-plated layer 3 provided on the surface of the galvanized layer 2 . The manufacturing method of the gravure roll comprises the following steps:

[0041] 1) machining the billet roll to obtain steel roll 1;

[0042] 2) Grinding and cleaning the surface of the steel roll 1 first, and then electroplating a layer of galvanized layer 2 on the surface of the steel roll 1, wherein the electroplating process is: placing the steel roll 1 in an electroplating solution, at an electroplating temperature of 40° C., a current of Density 5-25A / dm 2 Electroplating under the same conditions for 50min, each 1L electroplating solution includes the following components and contents: zinc 35g, boric acid 35g, potassium chloride 150g, additive 3mL and alkaline solution 30mL, the pH of the electroplating solution is...

Embodiment 2

[0052] A gravure roll containing a galvanized layer includes a steel roll 1 , a galvanized layer 2 arranged on the surface of the steel roll 1 , and a chrome-plated layer 3 arranged on the surface of the galvanized layer 2 . The manufacturing method of the gravure roll comprises the following steps:

[0053] 1) machining the billet roll to obtain steel roll 1;

[0054] 2) Grinding and cleaning the surface of the steel roll 1 first, and then electroplating a layer of galvanized layer 2 on the surface of the steel roll 1, wherein the electroplating process is: placing the steel roll 1 in an electroplating solution, at an electroplating temperature of 45° C., a current of Density 5-15A / dm 2 Electroplating under the same conditions for 40min, each 1L electroplating solution includes the following components and contents: zinc 45g, boric acid 30g, potassium chloride 180g, additive 2.2mL and alkaline solution 35mL, the pH value of the electroplating solution is 5.0, and the additiv...

Embodiment 3

[0064] A gravure roll containing a galvanized layer includes a steel roll 1 , a galvanized layer 2 arranged on the surface of the steel roll 1 , and a chrome-plated layer 3 arranged on the surface of the galvanized layer 2 . The manufacturing method of the gravure roll comprises the following steps:

[0065] 1) machining the billet roll to obtain steel roll 1;

[0066] 2) Grinding and cleaning the surface of the steel roll 1 first, and then electroplating a layer of galvanized layer 2 on the surface of the steel roll 1, wherein the electroplating process is: placing the steel roll 1 in an electroplating solution, at an electroplating temperature of 42° C., a current of Density 5-20A / dm 2 Electroplating under the same conditions for 45min, each 1L electroplating solution includes the following components and contents: zinc 40g, boric acid 32g, potassium chloride 170g, additive 2.7mL and alkaline solution 32mL, the pH value of the electroplating solution is 5.5, and the additiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com