Technology for producing ethanol through methyl acetate via methanol

A technology for producing methyl acetate and ethanol, which is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of increased reactor volume, large equipment consumption, serious equipment loss, etc. Not high, flexible operation, reduce the effect of heavy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

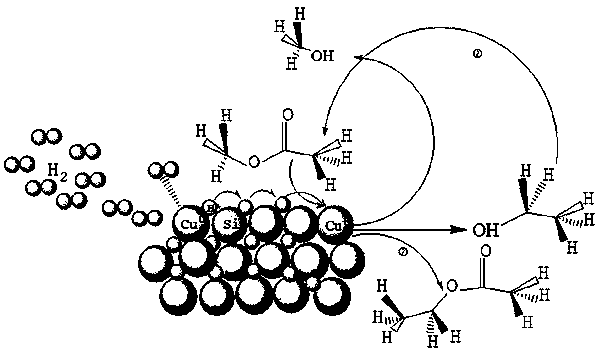

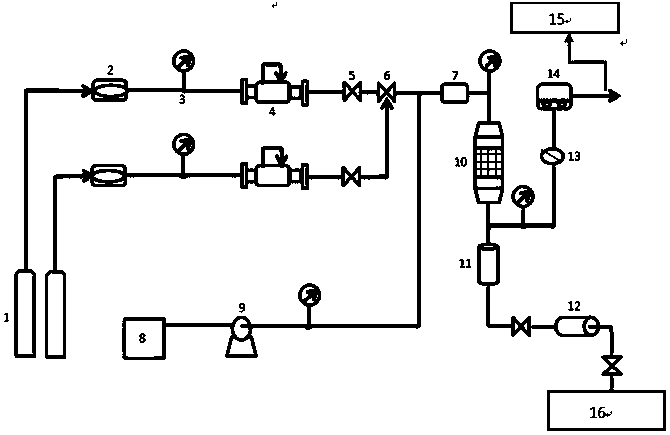

[0031] Methanol is used to provide a hydrogen source to the process flow of hydrogenation of methyl acetate to ethanol, and the specific embodiment includes: making the mixture of methyl acetate and methanol in a molar ratio of 3:1 in H 2 Under the atmosphere of the reaction device, the reaction temperature is 50°C and the reaction pressure is 0.5MPa. The gas-liquid separation device is used to separate the gas and liquid materials from the output materials of the reaction device. The liquid mixture is mainly the by-product after separating ethanol or the liquid phase The by-product after ethanol is separated from the mixture passes through the separated methanol, and then passes into the reactor together with methanol and methyl acetate as raw materials. From the liquid material output from the reaction device, the main product ethanol is separated by extraction and rectification. The selectivity is 90%. The by-products mainly include methyl acetate, ethyl acetate and unreacte...

Embodiment 2

[0033] A mixture of methyl acetate and methanol in a molar ratio of 4:1 in N 2 Add the reaction device under the atmosphere, the temperature should be 70 ℃ and the reaction pressure 1 MPa, the liquid space velocity 1h -1 , a gas-liquid separation device that separates gas and liquid materials from the output material of the reaction device, and separates gas N 2 Circulating to the reactor, the liquid material output by the device is separated by adding salt, extracting, rectifying and separating the main product ethanol with a selectivity of 92%, and the by-product methyl acetate, ethyl acetate is recovered and rectified to obtain other chemical raw products and unreacted acetic acid Methyl ester and methanol are recycled to the reactor for further reaction, wherein the conversion rates of methanol and methyl acetate are 87.34 and 90.12% respectively, and the selectivity of ethanol is 80.89%.

Embodiment 3

[0035] A mixture of methyl acetate and methanol in a molar ratio of 5:1 was 2 Add the reaction device under the atmosphere, the temperature should be 100 ℃ and the reaction pressure 1.2MPa, the liquid space velocity 2h -1 , a gas-liquid separation device that separates the gas and liquid mixture from the output material of the reaction device, and separates the gas CO 2 Circulate to the reactor, the liquid material output from the device is separated by adding salt, extracting, rectifying and separating the main product ethanol with a selectivity of 94%, and the by-products methyl acetate, ethyl acetate and unreacted methyl acetate and methanol are recycled to the reactor After further reaction, the selectivity of ethanol was 85.47%, the conversion rate of methanol reached 87.93%, and the conversion rate of acetic acid reached 79.78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com