Volume variable air conditioner compressor

An air-conditioning compressor and compressor technology, applied in the field of compressors, can solve the problems of changing the capacity of rotary compressors and energy waste, and achieve the effects of saving energy, reducing costs, and reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

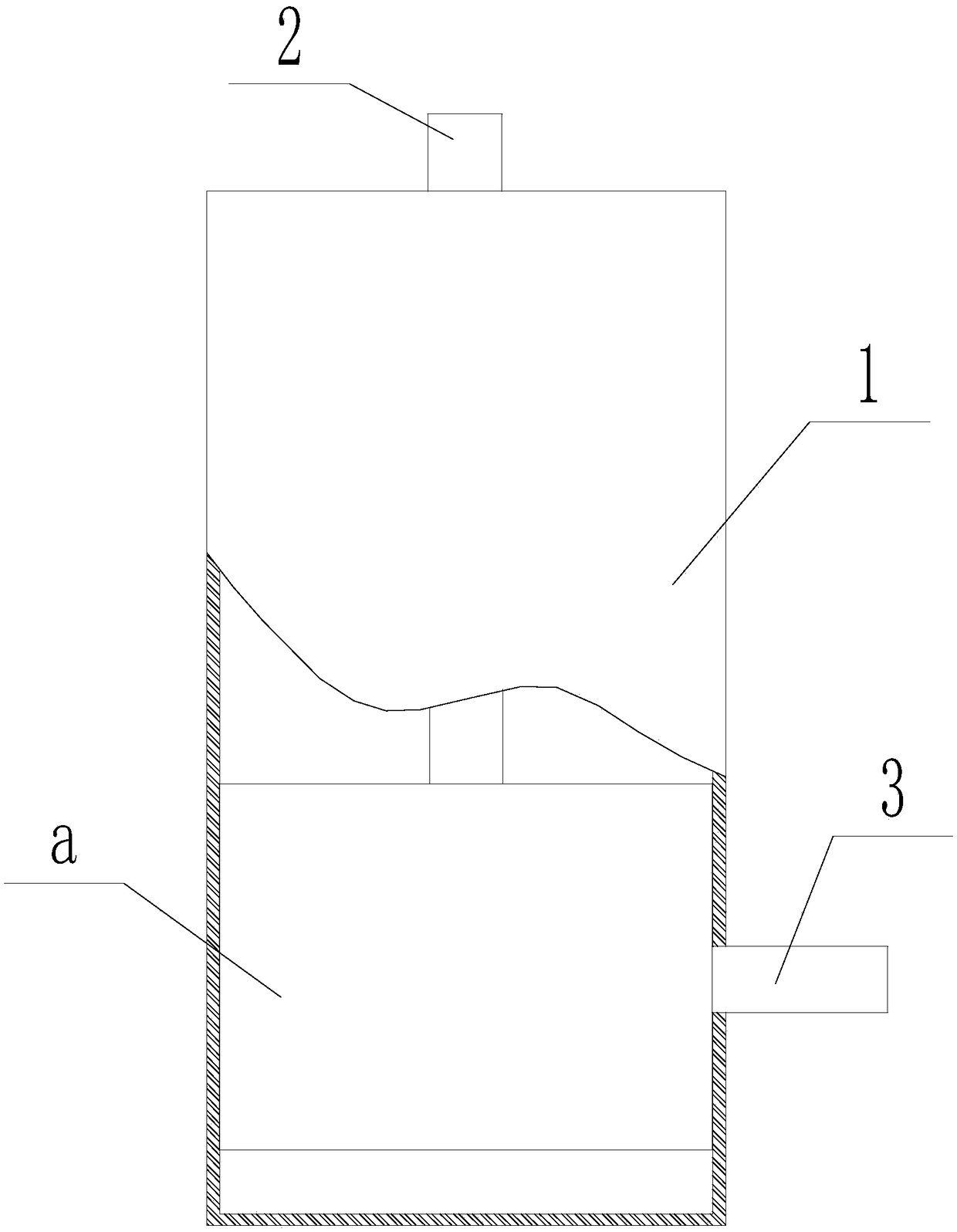

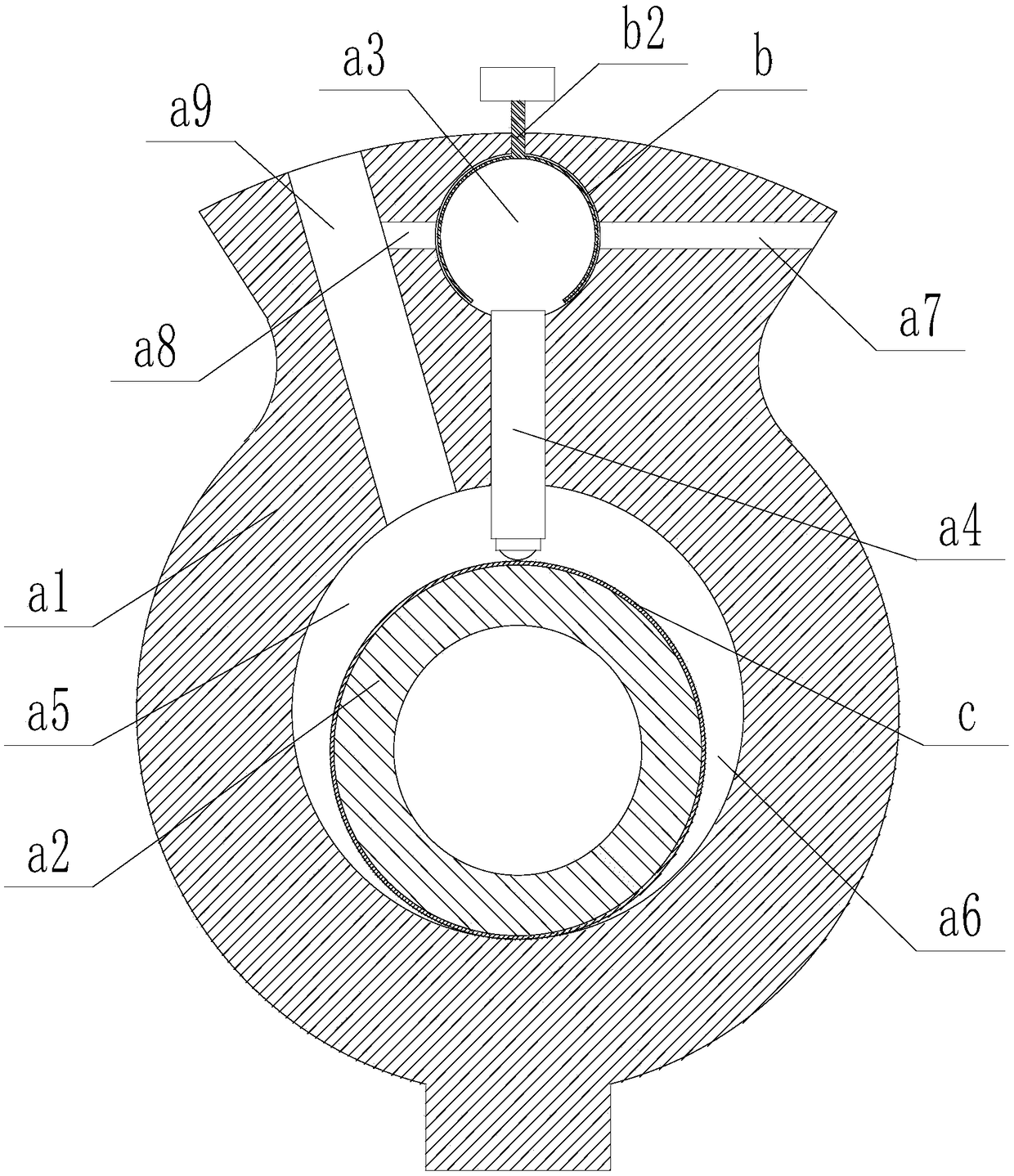

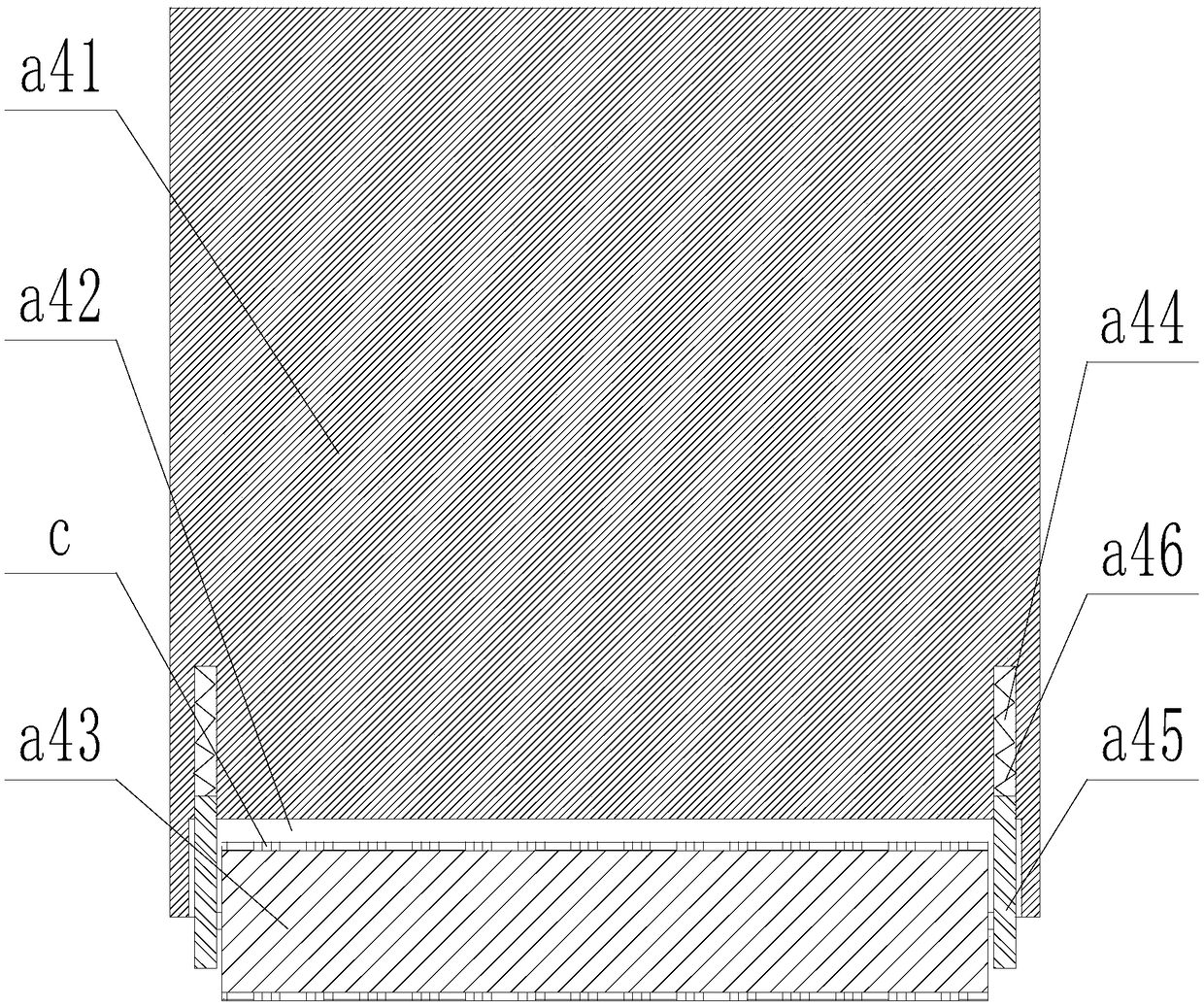

[0040] Such as Figure 1-5 As shown in , an air conditioner compressor with variable capacity includes a compressor casing 1, a refrigerant discharge pipe 2 is arranged on the top of the compressor casing 1, and a compression device a is arranged on the lower part of the compressor casing 1, The box wall of the compressor box 1 is provided with a refrigerant suction pipe 3, and the compression device a includes an annular cylinder a1 and an annular piston a2, and the annular piston a2 moves along the annular The inner wall of the cylinder a1 revolves so as to form a working chamber between the inner wall of the annular cylinder a1, the inner wall of the annular cylinder a1 is horizontally provided with a vane groove a3, and the isolation vane a4 is movable in the vane groove a3, The isolation blade a4 protrudes into the working chamber and abuts against the annular piston a2, and divides the working chamber into a suction chamber a5 and a compression chamber a6. The suction ch...

Embodiment 2

[0048] Such as Figure 1-5 As shown in , an air conditioner compressor with variable capacity includes a compressor casing 1, a refrigerant discharge pipe 2 is arranged on the top of the compressor casing 1, and a compression device a is arranged on the lower part of the compressor casing 1, The box wall of the compressor box 1 is provided with a refrigerant suction pipe 3, and the compression device a includes an annular cylinder a1 and an annular piston a2, and the annular piston a2 moves along the annular The inner wall of the cylinder a1 revolves so as to form a working chamber between the inner wall of the annular cylinder a1, the inner wall of the annular cylinder a1 is horizontally provided with a vane groove a3, and the isolation vane a4 is movable in the vane groove a3, The isolation blade a4 protrudes into the working chamber and abuts against the annular piston a2, and divides the working chamber into a suction chamber a5 and a compression chamber a6. The suction ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com