A combined heating system of gas-steam combined cycle and decarbonization system

A combined cycle and gas-steam technology, which is applied in heating systems, steam generation methods using pressure combustion, household heating, etc., can solve the problems of large steam extraction affecting the operation of steam turbines and wasting heat, so as to improve energy utilization efficiency and comprehensive performance, reduce heat waste, and reduce decarbonization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

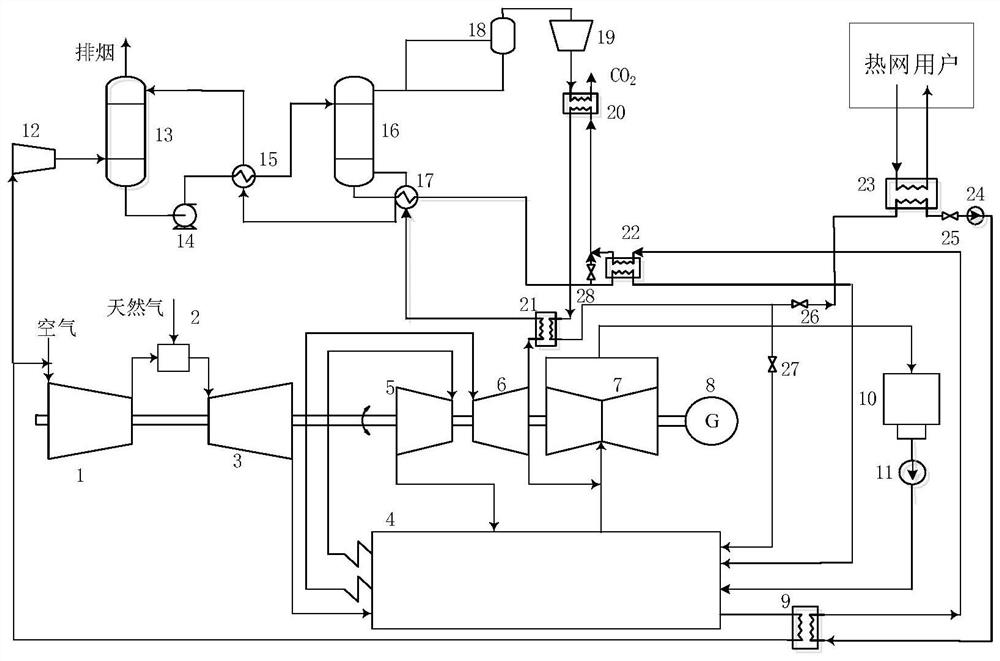

[0016] The present invention will be described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 shown. The present invention proposes a combined heating system of gas-steam combined cycle and decarbonization system, wherein the gas-steam combined cycle unit consists of a compressor 1, a combustion chamber 2, a turbine 3, a waste heat boiler 4, a steam turbine high-pressure cylinder 5, and a medium-pressure cylinder 6. Low-pressure cylinder 7, condenser 10, feed water pump 11, generator 8. The carbon dioxide capture unit is composed of a flue gas blower 12, an absorption tower 13, an absorption liquid pump 14, a lean-rich liquid heat exchanger 15, a desorption tower 16, a reboiler 17, a carbon dioxide separator 18, and a carbon dioxide compression unit 19. The user heating network unit is composed of heating network users, heating network water circulation pump 24 and its circulation loop.

[0018] Among them, the compressor 1 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com