Printing nail lacquer and preparation technology and using method thereof

A technology for nail polish and printing, applied in the field of nail beautification treatment, can solve the problems of time-consuming, difficult adhesion of nail polish, etc., and achieve the effect of reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

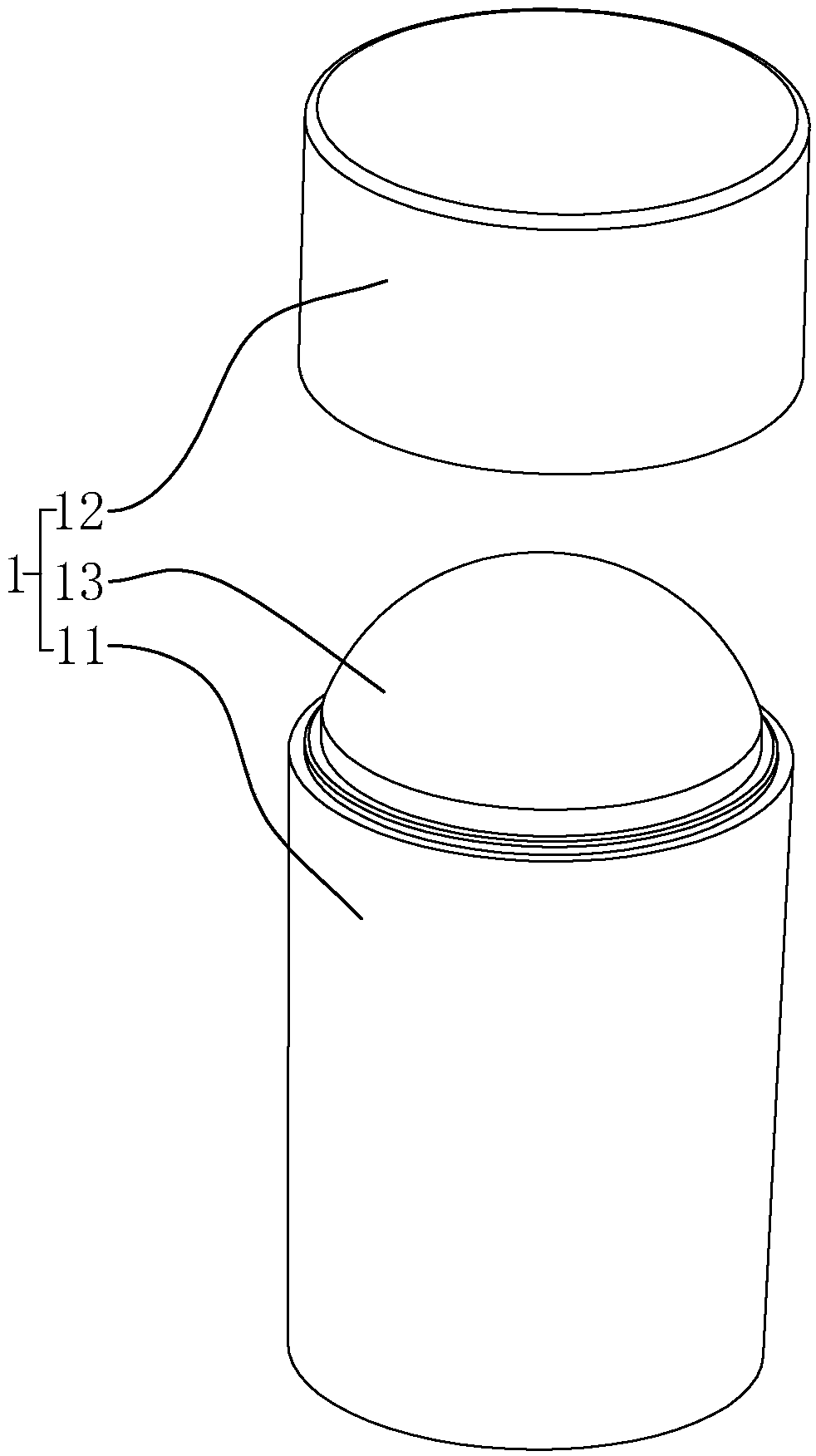

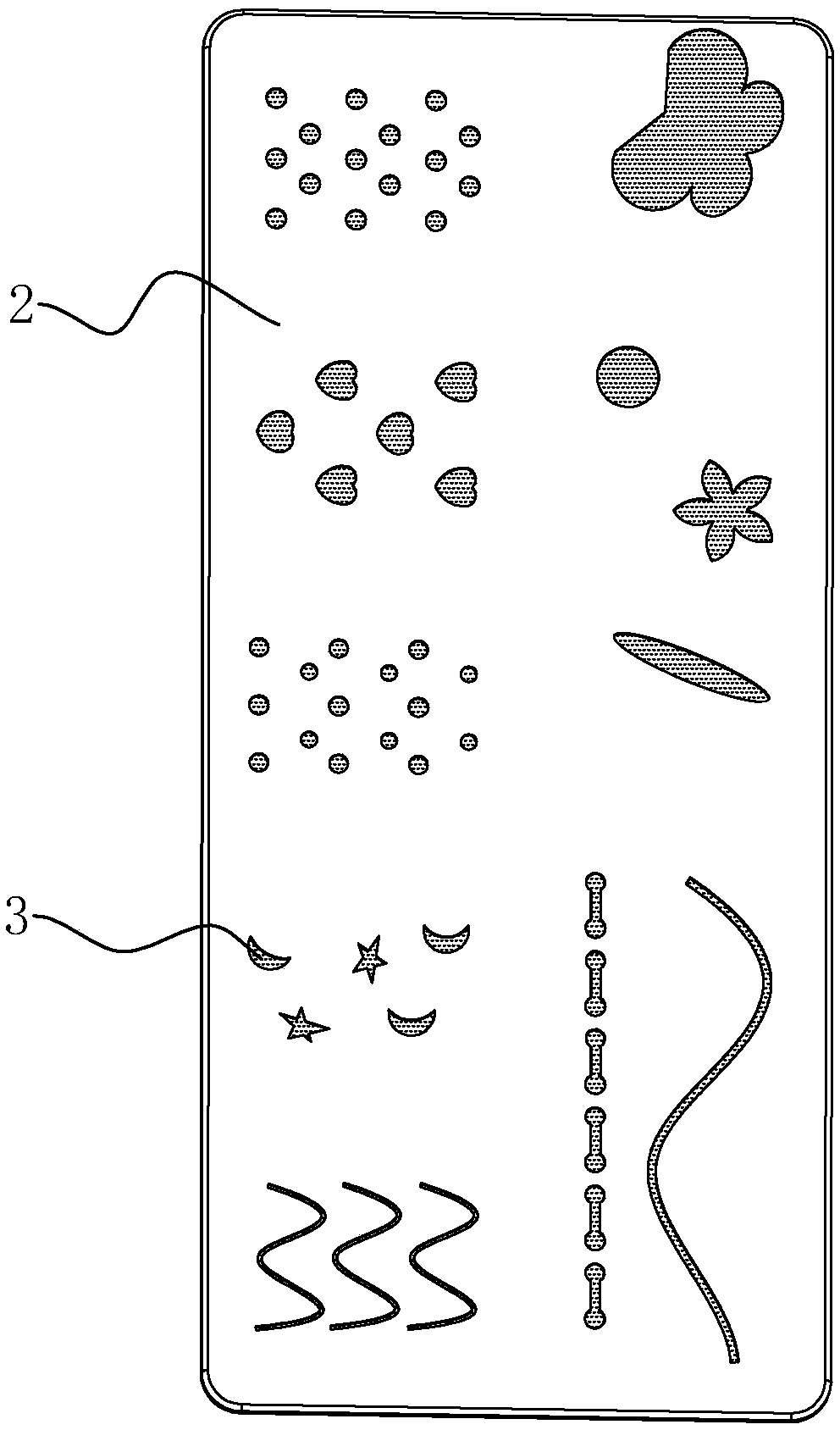

Image

Examples

Embodiment 1

[0074] Embodiment 1: A printed nail polish, the components included and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0075] Step 1, fully mix deionized water, half ethanol, film-forming agent, active agent, bentonite, nano-microcrystalline cellulose colloid, and preservative at a speed of 1300-1600rpm to form the first mixture,

[0076] Step 2: Divide the evenly dispersed coloring agent into the first mixture obtained in step 1 in 3-5 times on average, and stir at a speed of 1500-1700 rpm for 1-2 minutes after each addition, and after all the coloring agent is added, Then mix at a speed of 1200-1500rpm for 25-40min, and mix thoroughly to obtain the second mixture;

[0077] Step 3, add the other half of ethanol to the second mixture obtained in step 2, and mix thoroughly to obtain printed nail polish.

[0078] Wherein, film-forming agent is acrylic acid (ester) class / VA copolymer; Active agent selects sodium dodecylb...

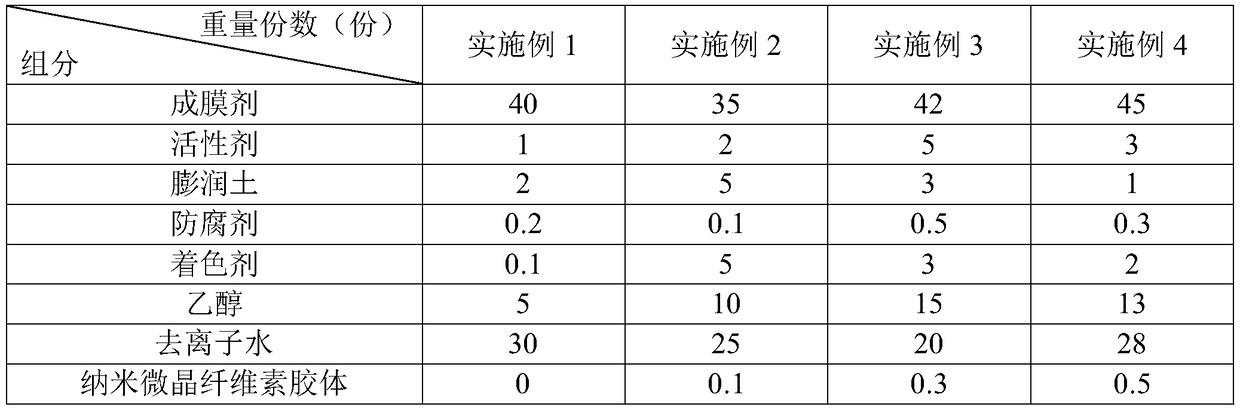

Embodiment 2-4

[0080] Embodiment 2-4: A printed nail polish, the difference from Embodiment 1 is that the components included and their corresponding parts by weight are shown in Table 1. Wherein, in the nanocrystalline cellulose colloid in embodiment 2-4, the percentage of nanocrystalline cellulose is respectively 0.01wt%, 0.06wt%, 0.03wt%, and nanocrystalline cellulose is spherical, and particle size is 50-80nm.

[0081] Components included in Table 1 Embodiment 1-4 and their corresponding parts by weight

[0082]

Embodiment 5

[0083] Embodiment 5: A printed nail polish, the difference from Embodiment 1 is that the film-forming agent is polyvinylpyrrolidone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com